Deep horizontal displacement automatic monitoring device

A technology of horizontal displacement and monitoring device, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of difficult to eliminate the gravitational acceleration error, time-consuming and labor-intensive, and great influence on measurement accuracy, so as to solve the problem of gravity acceleration. Acceleration error, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

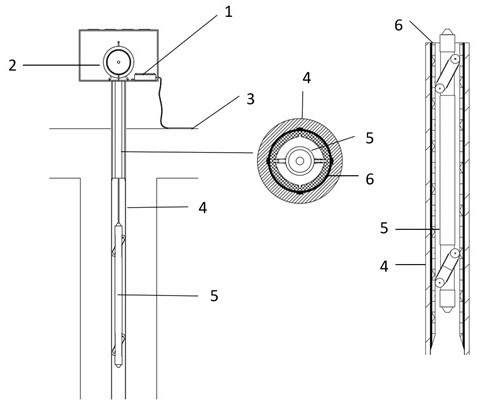

[0021]Such asfigure 1As shown, a deep horizontal displacement automation monitoring device includes a power supply module 3, a acquisition control module 1, a boost module 2, a rotation module 6, a sensor integrated module 5, a tube 4; the power supply module 3 is a acquisition control module 1, improved Module 2, the sensor integrated module 5, the rotation module 6 provides an energy source; the acquisition control module 1 and the lifting module 2 are connected by a wire connection, and the boost module 2 and the sensor integrated module 5 are connected by a composite wire, and the acquisition control module 1 acquires from the sensor integrated module 5. Data, and transmit data through wireless signals; the composite wires are complicated with cable, and the control sensor integrated module 5 is controlled and deceased; the acquisition control module 1 and the rotation module 6 are connected by a wire, and the rotation module 6 and the tube 4 pass through the inner wall. The tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com