Bitumen-like material creep test device

A creep test and asphalt technology, applied in the field of testing equipment, can solve the problems of high complexity of equipment, expensive equipment, and high equipment maintenance cost, and achieve the effect of shortening design size, simple equipment and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

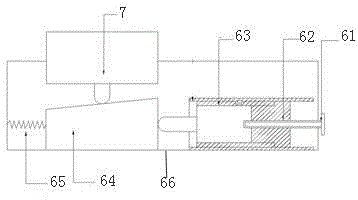

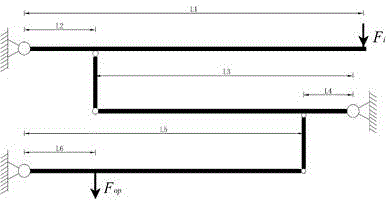

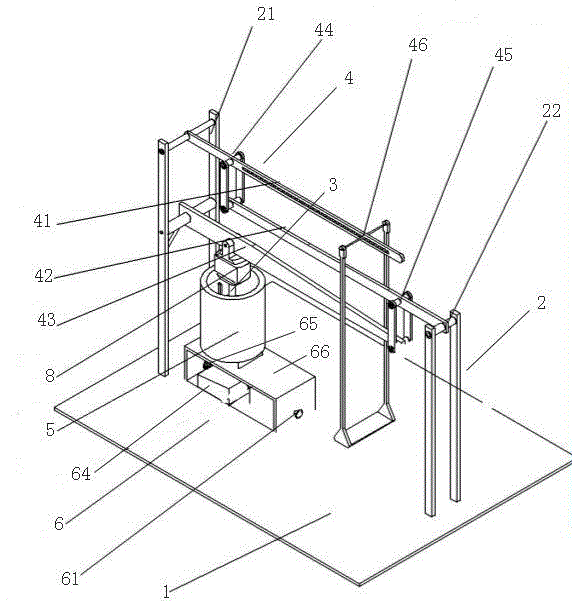

[0019] The research idea of the present invention is to adopt a three-stage turn-back lever booster system, and to apply a constant external force through weight loading and a lever structure, so as to realize the creep performance test of asphalt materials. At the same time, the angle feed system is used to compensate the small deformation of the specimen during the creep process, so that the lever booster mechanism maintains better working performance. The finite element method is used to calculate and analyze the internal force and deformation of the creep testing machine, and check the component stress, so as to ensure that the machine has good strength and stiffness characteristics.

[0020] like image 3 Shown is the working principle diagram of the foldback three-stage series booster three-stage lever booster structure. The device is mainly composed of three-stage series booster levers and a dowel bar in the middle. If a downward force F is applied to the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com