System and method for characterization of buried defects

A defect and subsystem technology, applied in the field of defect inspection and classification, which can solve problems such as inability to accurately measure size and depth, detection and/or measurement difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention has been particularly shown and described with respect to particular embodiments and its particular features. The embodiments set forth herein are to be regarded as illustrative and not restrictive. It will be readily apparent to those skilled in the art that various changes and modifications in form and details can be made without departing from the spirit and scope of the invention.

[0017] Reference will now be made in detail to the disclosed subject matter illustrated in the accompanying drawings.

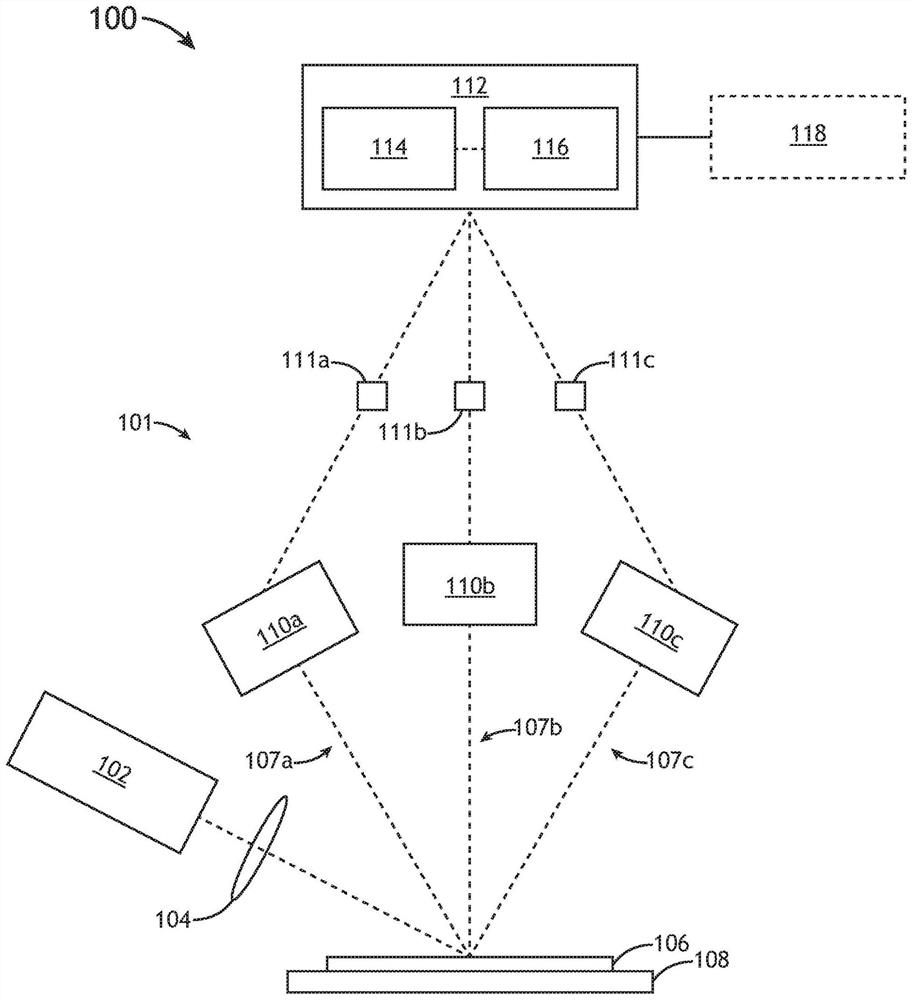

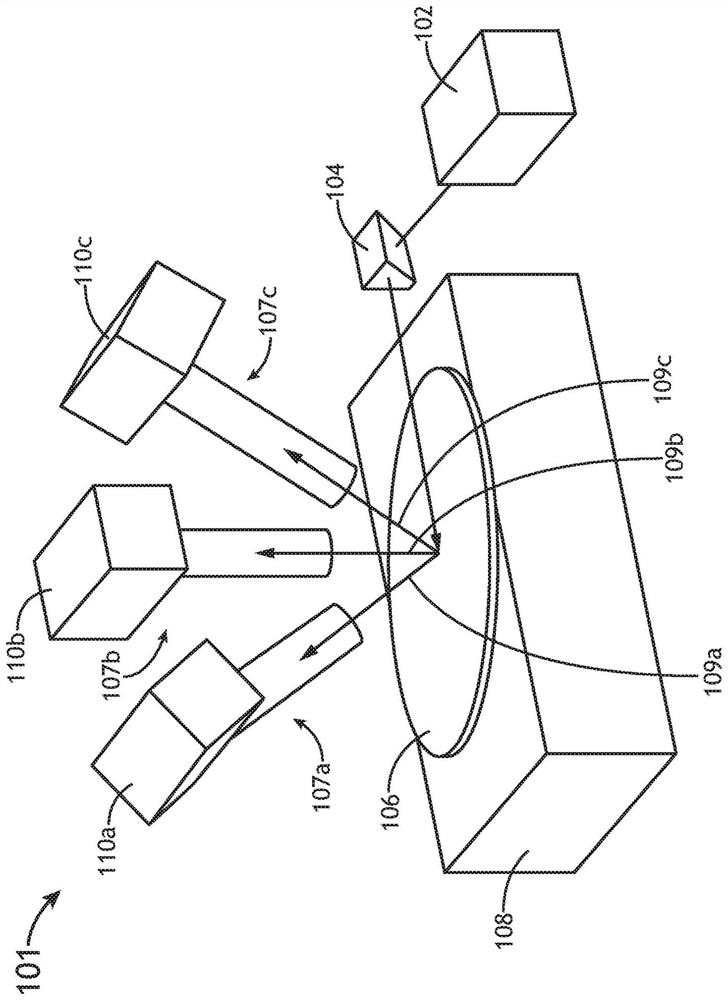

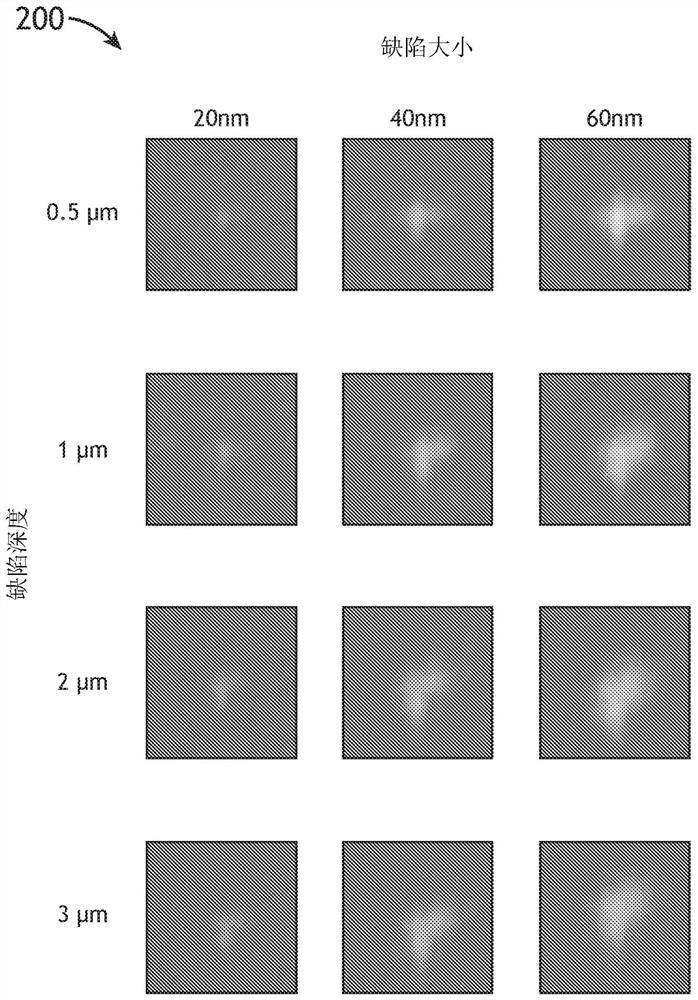

[0018] generally refer to Figures 1A to 6 , systems and methods for defect detection and classification using machine learning are shown and described in accordance with one or more embodiments of the invention.

[0019] Embodiments of the invention relate to defect detection and classification using machine learning classifiers (eg, defect classifiers). More specifically, embodiments of the invention relate to training a defect classifier using images...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com