A construction method for synchronous lateral movement of high and low span grid structures

A technology of grid structure and construction method, applied in special structures, building components, building structures, etc., can solve problems such as heavy workload, and achieve the effect of reducing overall workload, not easy to bend, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

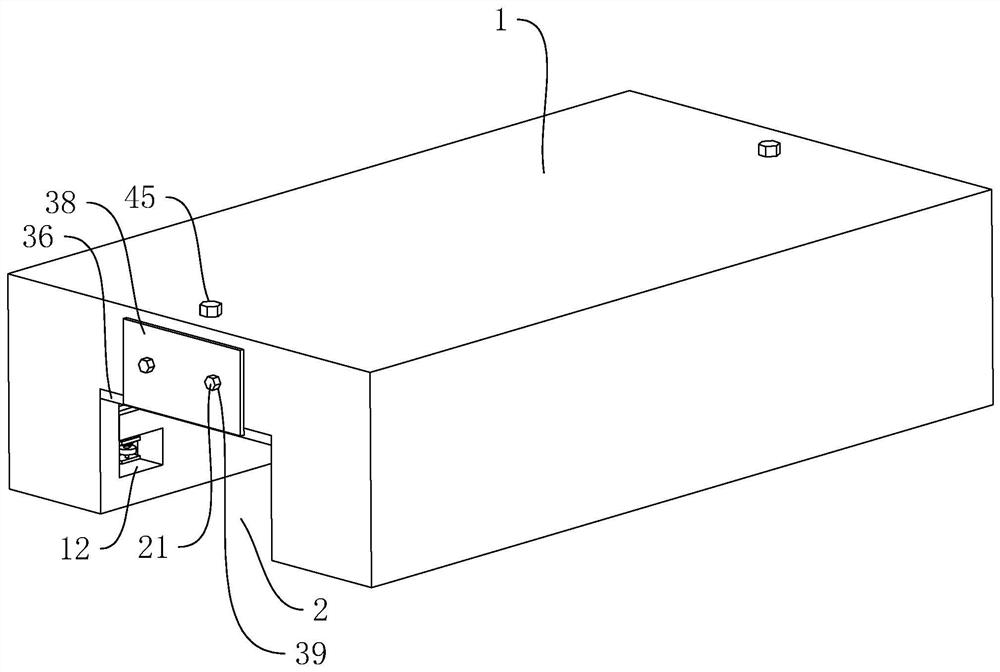

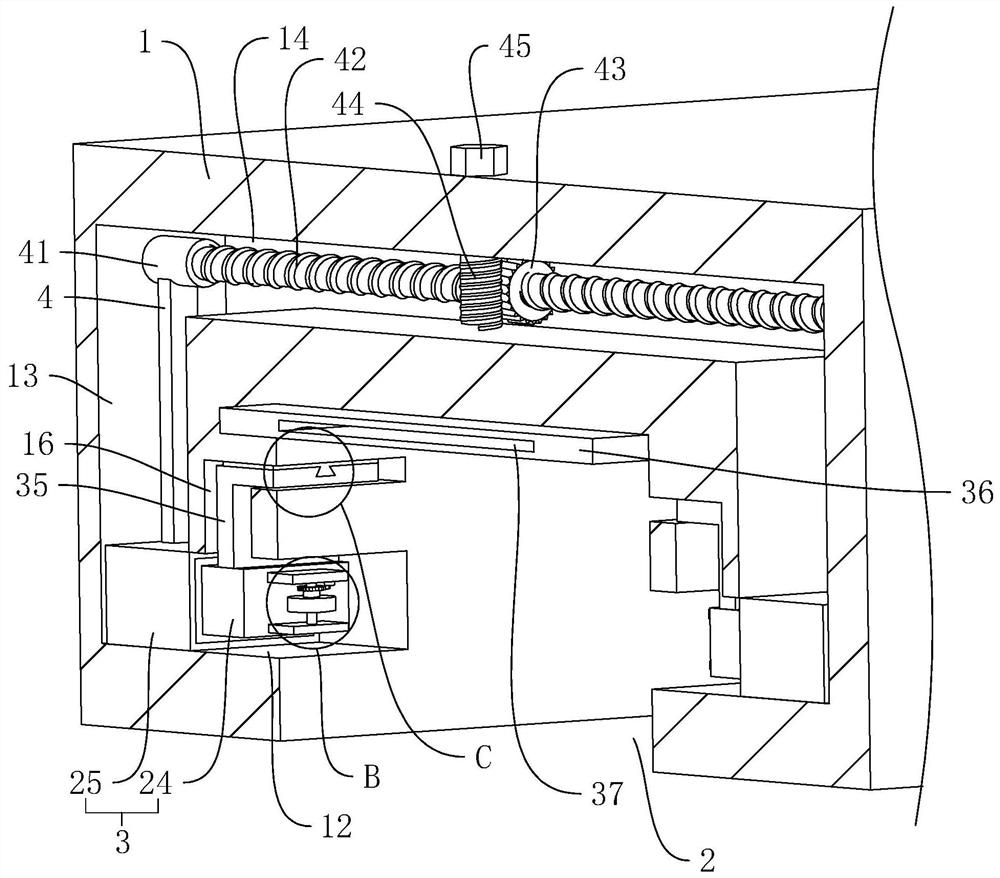

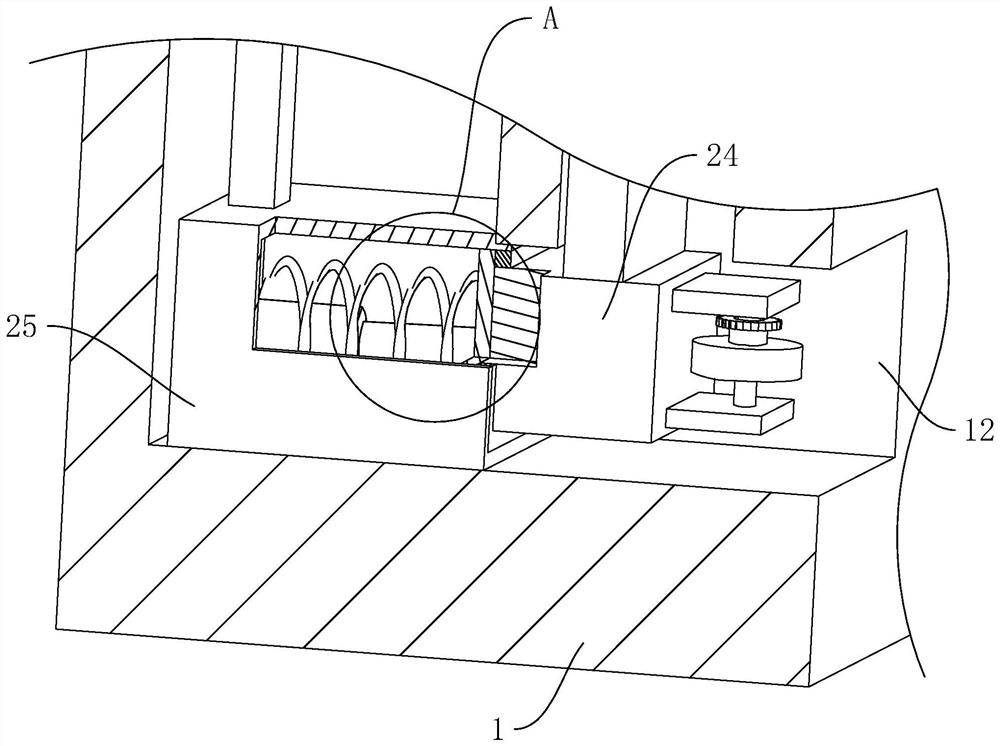

[0038] The present application will be further elaborated below in conjunction with all the drawings.

[0039] Embodiments of the present application disclose a construction method of synchronous traversal of high and low spanning frame structures, with reference Figure 1 and Figure 2 , which includes the following steps:

[0040] Step 1: Build the assembly platform and assemble the first frame segment on the assembly platform;

[0041] Step 2: Slide rails are laid on both sides of the concrete columns, and the slide rails are H-shaped steel;

[0042] Step 3: Build a temporary support between the two slide rails, and lay a third slide on the temporary rail;

[0043] Step 4: The first grid frame segment is lowered to the slide rail, the track clamping equipment and the slide rail are connected, and then the power rod of the hydraulic cylinder that is articulated with the track clamping equipment and the structural support that is fixed to the first grid frame segment are articulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com