Aggregate mud content test method and elutriation container

A test method and mud content technology, applied in separation methods, chemical instruments and methods, weighing by removing certain components, etc., can solve problems such as splashing, inaccurate test results, residues, etc.

Inactive Publication Date: 2021-04-27

中铁大桥局集团第六工程有限公司 +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The embodiment of the present application provides a test method for the mud content of aggregates and an elutriation container to solve the problem of residues or

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

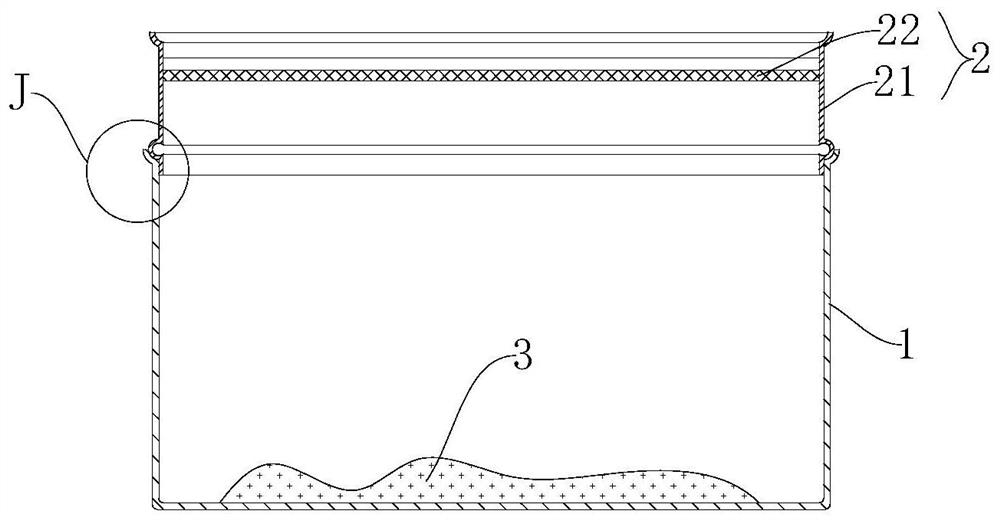

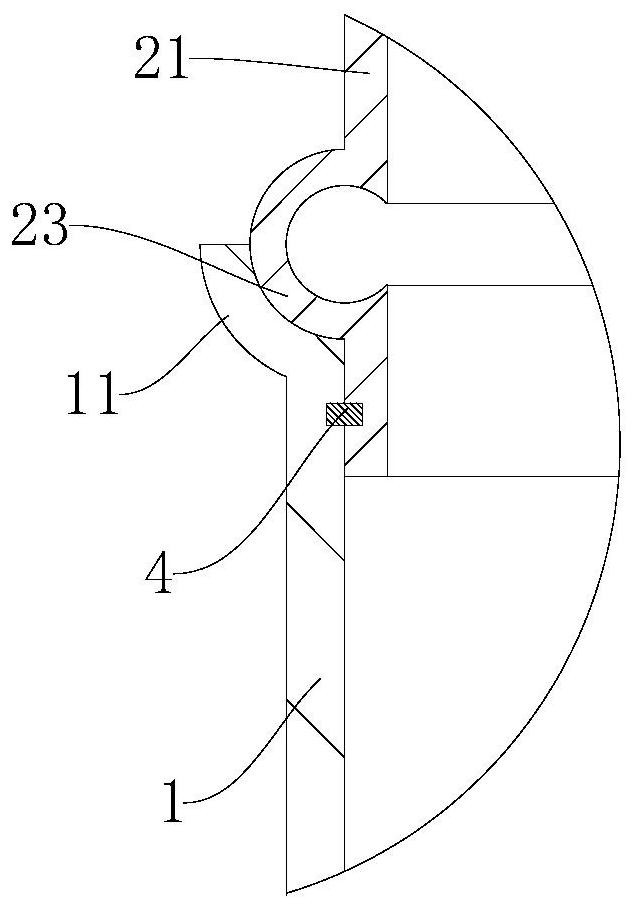

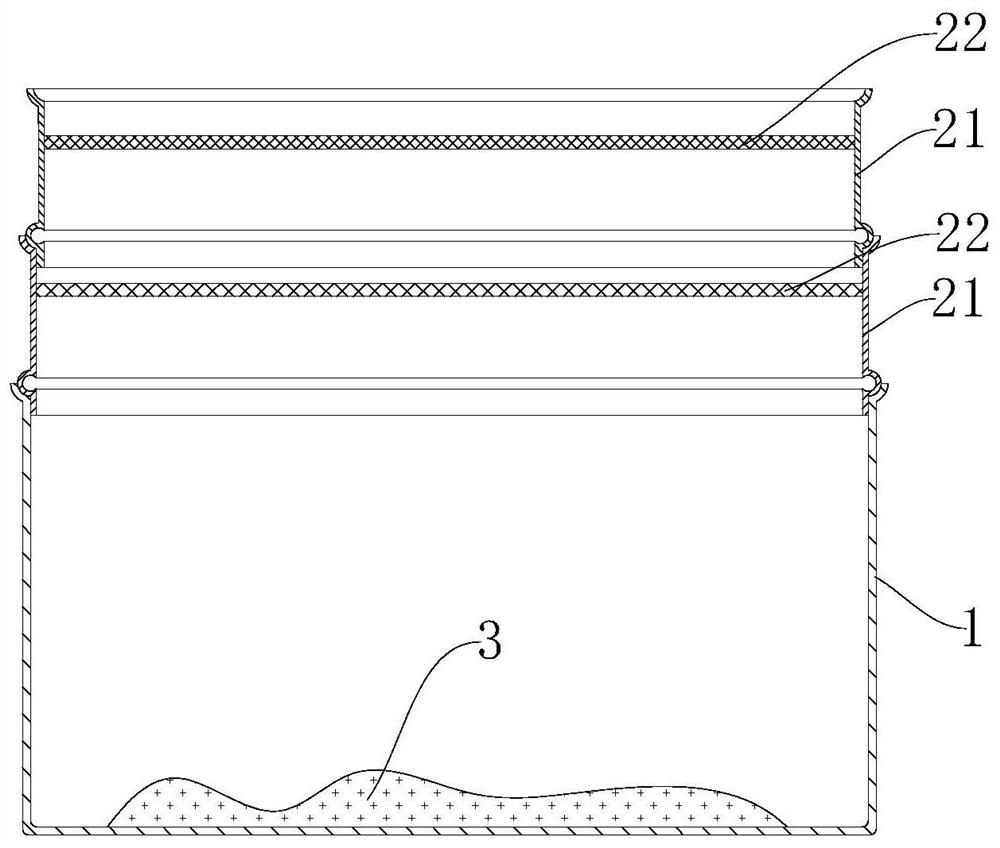

The invention belongs to the technical field of aggregate detection tests and relates to an aggregate mud content test method and an elutriation container. The test method comprises the steps that: an elutriation container is provided, wherein the elutriation container comprises a shell body and a shell cover, wherein the shell cover comprises at least one shell cover unit, wherein each shell cover unit comprises a screen through which particles of which the diameters are smaller than a preset value can pass; the elutriation container and an aggregate sample to be tested are weighed; the weighed aggregate sample is put into the shell body, and the shell body is covered with the shell cover unit; the elutriation container is used for elutriating the aggregate sample, and the particles are filtered out through the screen until a water sample in the shell body is clear; and the elutriation container filled with the elutriated aggregate sample is integrally dried and weighed, so that mud content test can be finished. The method is easy and convenient to operate, efficient and accurate in test result.

Description

technical field [0001] The present application relates to the technical field of aggregate detection and testing, in particular to a test method for mud content of aggregates and an elutriation container. Background technique [0002] In engineering applications, the mud content and mud block content tests in aggregate testing tests are indispensable testing parameters in various construction site tests. In the industry standard E42 and national standards GB 14684 and GB 14685, clay, silt, stone chips and other powders with a particle size of less than 0.075mm are collectively referred to as mud. The steps for the operation of aggregate mud content and mud content are: [0003] Take a portion of the dried sample and place it in the cylinder, and inject clean water until the water surface is about 200mm above the sand surface, stir well, soak for 24 hours; then wash the sample in water by hand to remove dust and silt Separate from clay and sand, and suspend them in water, sl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N5/04

CPCG01N5/04B01D29/03

Inventor 沈彬彬单洋洋刘琴梅朱昌华张慕远晏邦泽

Owner 中铁大桥局集团第六工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com