Hydraulic practical training platform

A training platform and hydraulic technology, applied in the field of training equipment, can solve the problems of limited floor area, low demonstration effect, and low demonstration efficiency, and achieve the effects of improving efficiency, reducing distance, and ensuring viewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

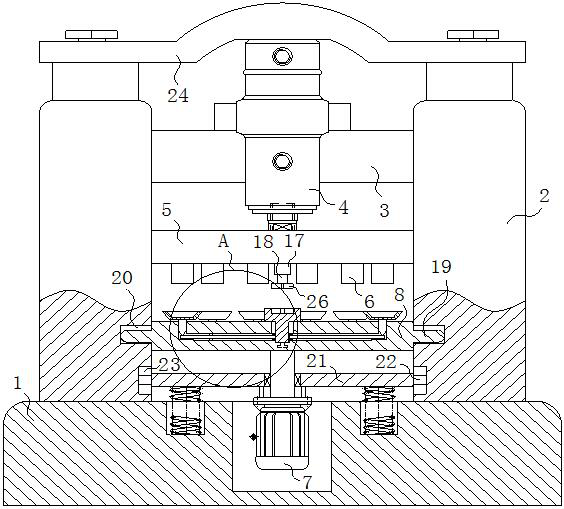

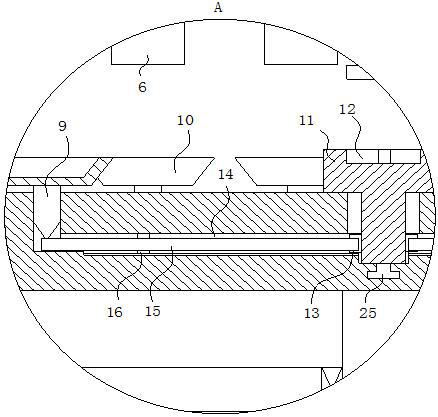

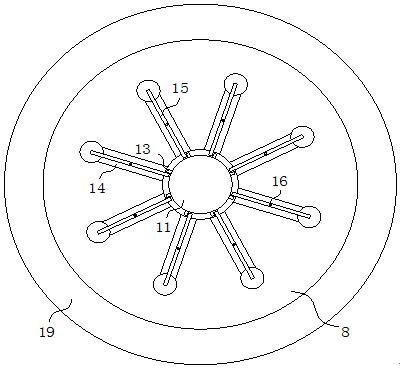

[0031] As a specific embodiment of the present invention, the distance from the annular disk 19 to the bottom of the slot 20 is smaller than the distance from the support rod 9 to the bottom of the slot; The distance to move up is large.

[0032] As a specific embodiment of the present invention, the bottom end of the rotating rod 11 is fixedly connected with an inverted T-shaped disk 25, and the inverted T-shaped disk 25 is located in the rotating disk 8 at the bottom of the central groove; the groove wall of the cross groove 12 and The outer surface of the cross 26 has been polished; the inverted T-shaped plate 25 can limit the rotation rod 11 when the cross 26 rises from the cross groove 12, preventing the cross 26 from driving the rotation rod 11 up, and the cross groove 12 The groove wall and the outer surface of the cross 26 are all polished to reduce the friction between the two, and the cross 26 can be quickly removed from the cross groove 12.

[0033] As a specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com