An intelligent lifting device for a hanging welding robot

A welding robot, lifting device technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of difficult welding, lack of stability and safety, etc., to ensure quality, convenience and stability , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

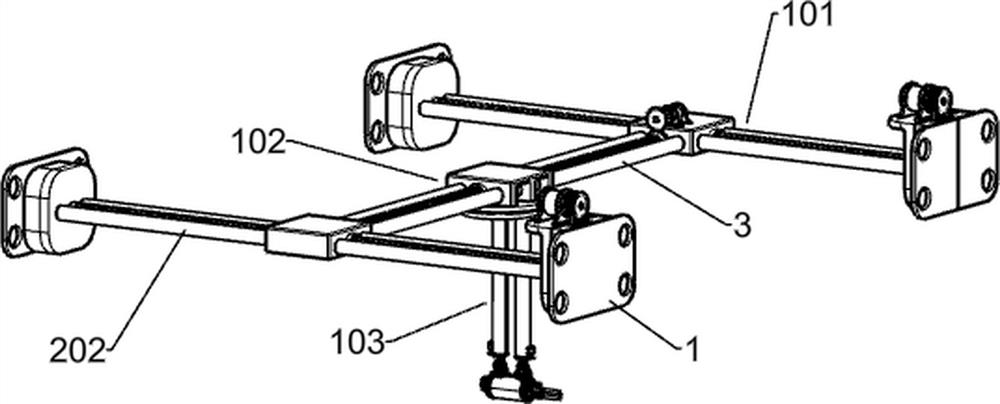

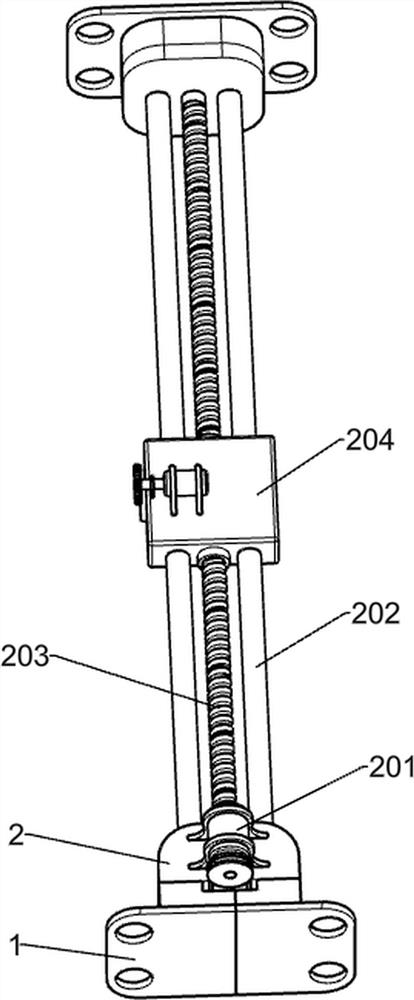

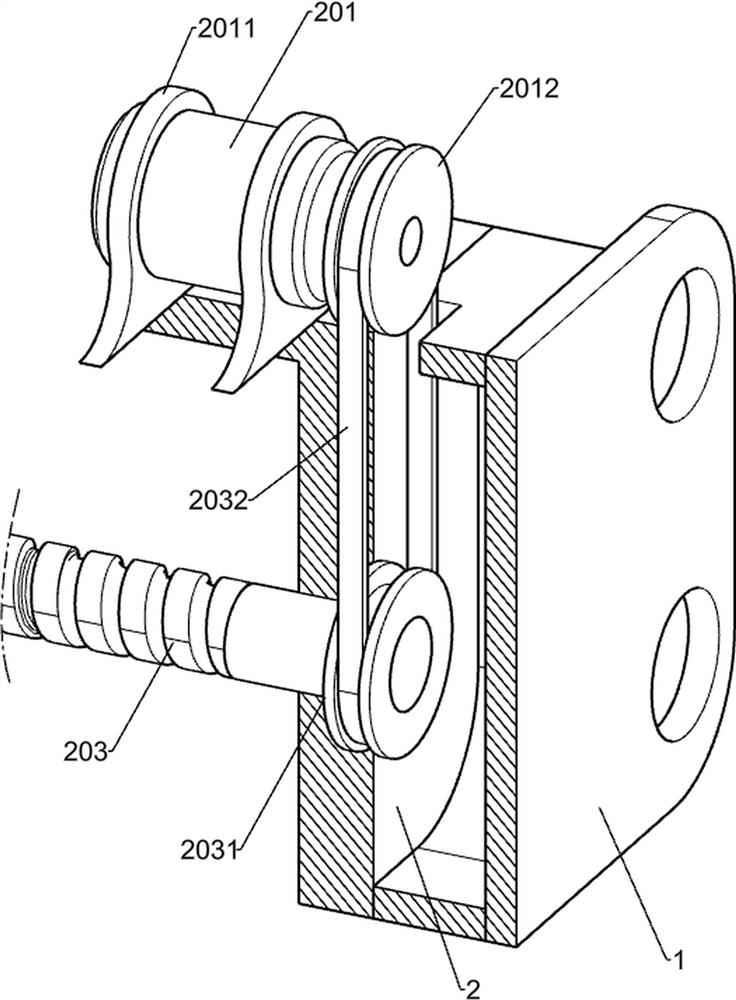

[0033] Such as figure 1As shown, an intelligent lifting device for a hanging welding robot includes a mounting plate 1, an X moving unit 101, a Y moving unit 102, a telescopic welding angle adjusting device 103, a welding rotation angle adjusting device and a handle protection assembly, two pairs of installation An X mobile unit 101 is installed on each board 1, and a Y mobile unit 102 is connected to the X mobile unit 101, and a telescopic welding angle adjustment device 103 is connected to the Y mobile unit 102, and the X mobile unit 101 is in the form of a screw slide table Translating the Y moving unit 102, the Y moving unit 102 translates the telescopic welding angle adjustment device 103 in the form of a lead screw slide table, the telescopic welding angle adjustment device 103 is connected with a welding rotation angle adjustment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com