Drying and dedusting integrated equipment for fireproof plate production and fireproof plate production method

The technology of fireproof board and equipment is applied in the field of integrated drying and dust removal equipment for fireproof board production and fireproof board production, which can solve the problems of incomplete drying, low efficiency and high labor cost, and achieve good drying effect and structure. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

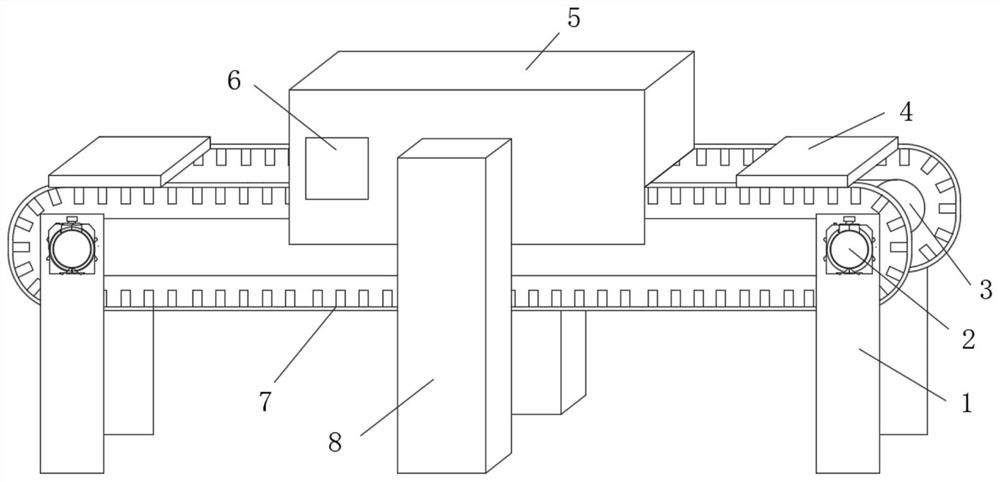

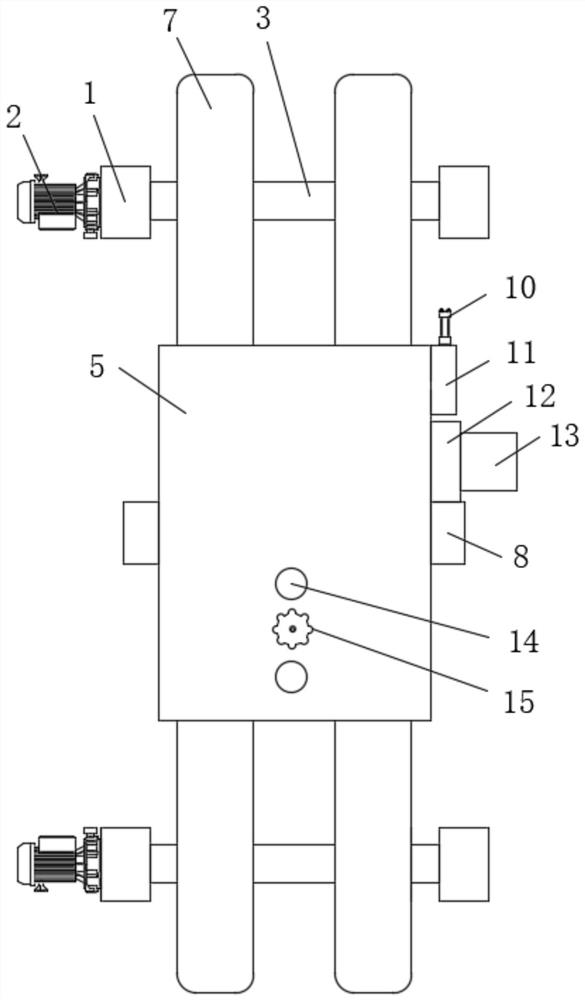

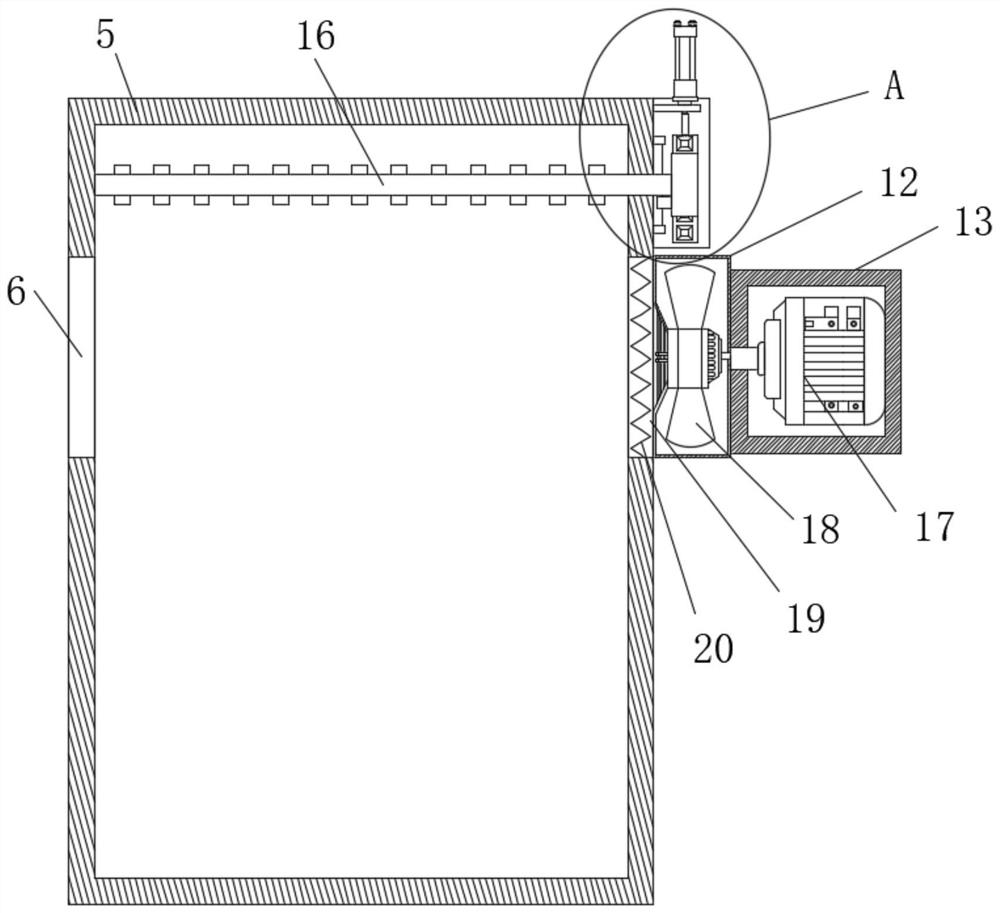

[0031] refer to Figure 1-10 , an integrated drying and dust removal equipment for the production of fireproof boards, including a fireproof board body 4 and two symmetrically arranged second support columns 8, the sides of the two second support columns 8 close to each other are fixedly connected with the same rectangular cover 5. A transmission component for transmitting the fireproof board body 4 is arranged directly under the rectangular cover 5, the fireproof board body 4 is placed on the transmission component, and one side of the rectangular cover 5 is fixedly connected with a dust removal component for removing dust from the fireproof board body 4, One side of the rectangular cover 5 is fixedly connected with a pre-drying assembly for pre-drying the fireproof board body 4, and the top inner wall of the rectangular cover 5 is provided with a drying assembly for drying the fireproof board body 4. In the present invention, by The transmission component transmits the firep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com