Elastic sweeper for belt conveyor

A technology for belt conveyors and cleaners, applied in the field of cleaners, can solve the problems of poor cleaning effect of cleaners, easy sticking of materials on the surface of the belt, complex cleaner structure, etc., and achieve novel structural design, low cost, and reduced impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

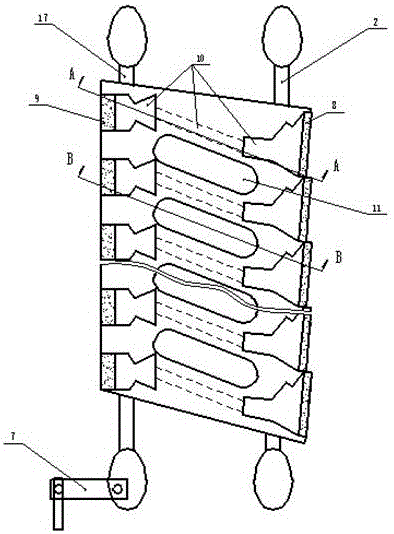

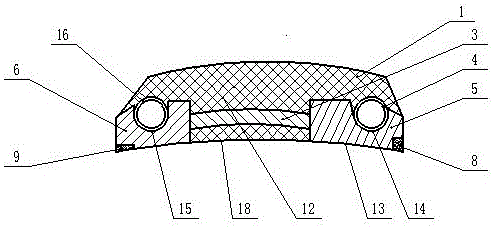

[0027] An elastic cleaner for a belt conveyor, comprising an elastic base 1, a first tensioned steel wire rope 2, a second tensioned steel wire rope 17, an upper knife rest 5, a lower knife rest 6, a wear-resistant upper knife head 8, and a wear-resistant lower knife head 9 and the tensioning device 7, the first row of the elastic base 1 is composed of several upper knife rests 5 closely arranged, and the upper knife rest 5 is provided with a wear-resistant upper cutter head 8, and the wear-resistant upper cutter head 8 is welded and fixed together with the upper knife rest 5; the elastic substrate 1 in the second row is composed of several lower knife rests 6, and the lower knife rest 6 is provided with a wear-resistant lower cutter head 9; the wear-resistant lower The cutter head 9 and the lower tool rest 6 are welded and fixed together, the wear-resistant upper cutter head 8 and the wear-resistant lower cutter head 9 are made of hard alloy, and its hardness HRC is greater th...

Embodiment 2

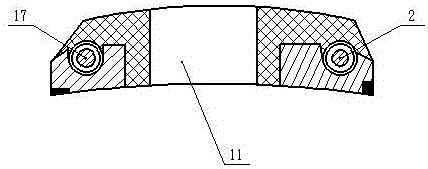

[0033] In the present embodiment, the installation of elastic sweeper and belt surface 21 is as follows: Figure 6 As shown, the elastic cleaner is close to the belt surface 21 due to the tightening of the first tension wire rope 2 and the second tension wire rope 17, and the cleaner is obliquely installed on the belt surface, the first tension wire rope 2 and the belt surface The included angle between the tangential direction of the second tension wire rope 17 and the axial direction of the belt drum is 30︒. When the elastic sweeper of the present invention is installed, it adopts oblique installation, so that the blade is obliquely bound on the drum, and the upper blade and the belt pulley axis have a certain The angle of the belt can reduce the impact of the blade on the belt surface, which can greatly reduce the resistance of cleaning.

[0034] The invention has a novel structural design, fully utilizes the high-hardness material to clean the belt surface, has high efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com