Double lower rail structure of opposed type sliding doors

A technology for sliding doors and guide rails, which is applied in the direction of doors, transmissions, door/window accessories, etc., which can solve the problems of poor vehicle design freedom, inability to stably support sliding doors, and increased vehicle weight to achieve the effect of preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

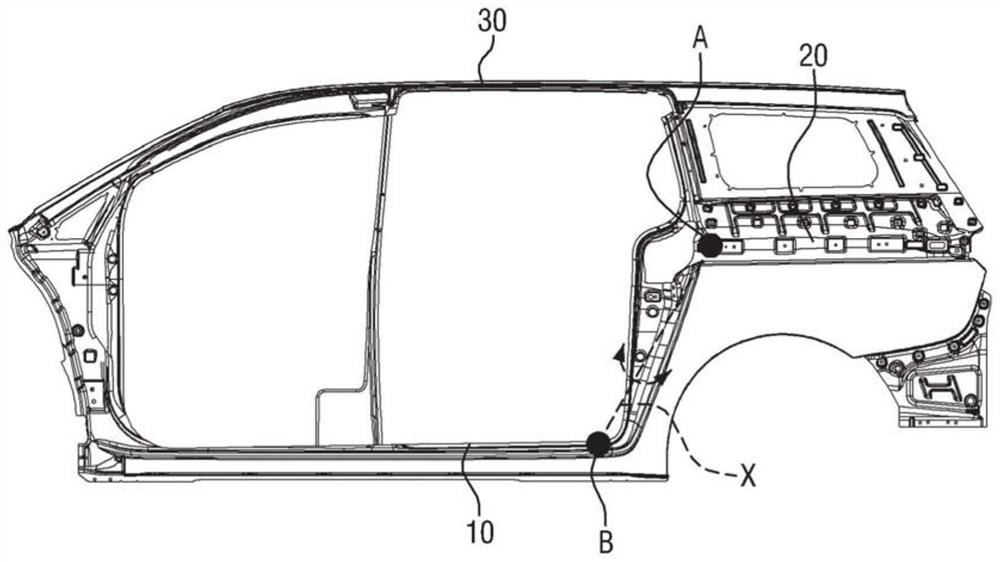

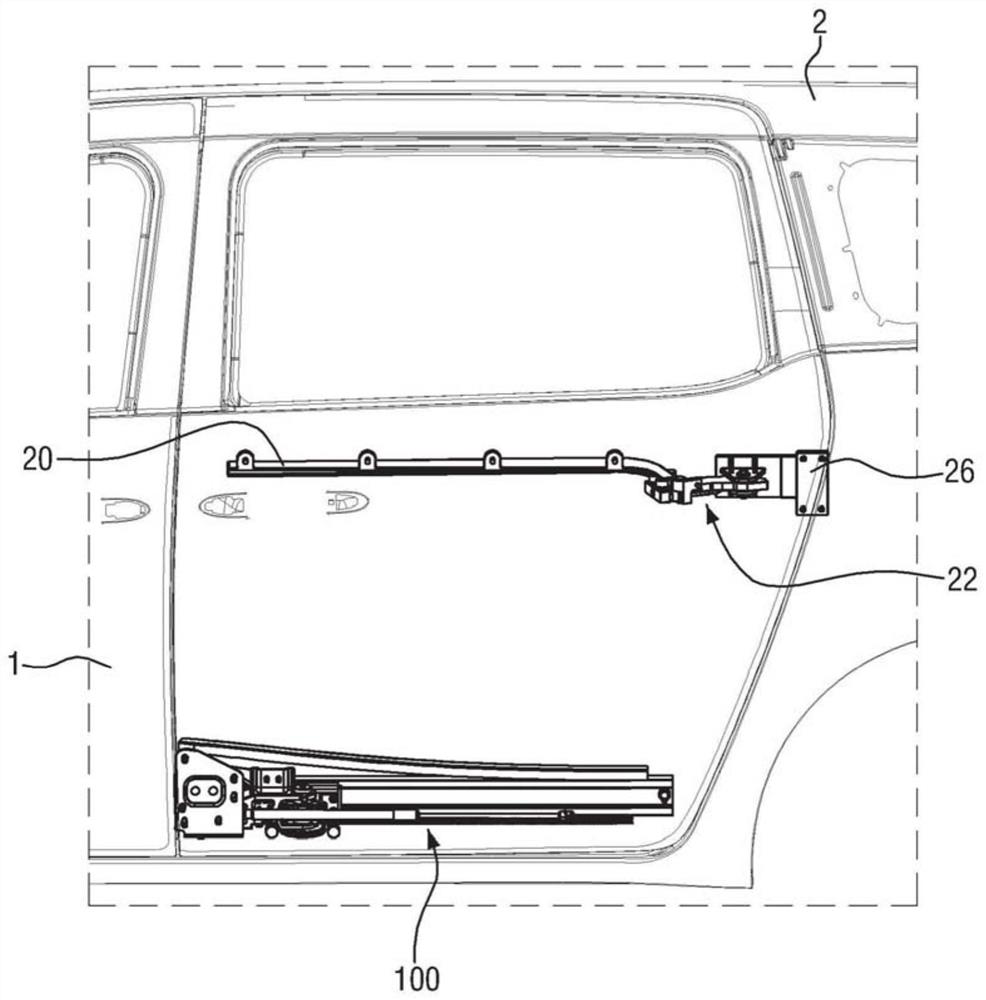

[0049] The floor space 150 is a space formed in advance when designing a vehicle on which the sliding door is installed, and the first lower rail 110 and the second lower rail 120 are not exposed outside the floor space 150 (outside of an open portion of the floor space). Therefore, according to the exemplary embodiment of the present invention, the vehicle in which the sliding door is installed is excellent in appearance, there is no obstacle in the moving route when the user gets on or off the car, and the floor space formed in the related art 150 may be used to install the first lower rail 110 and the second lower rail 120 without changing the design of the vehicle body 2 .

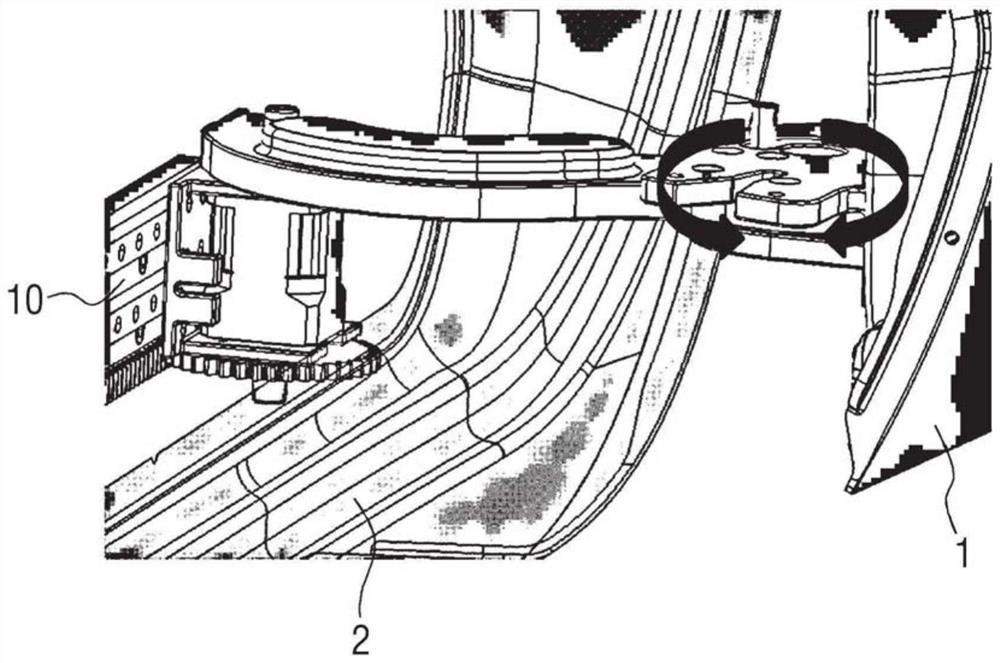

[0050] refer to Figure 7 , the first lower rail roller unit 130 is rollably connected to the first lower rail 110 . Specifically, the first roller 132 of the first lower rail roller unit 130 is inserted into the first roller insertion portion 112 of the first lower rail 110 . The first roller 132 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com