Angle adjusting piece for steel support

An angle adjustment, steel support technology, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as unable to provide support, irregular shape of foundation pit, etc., to achieve flexible angle adjustment, wide application range, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

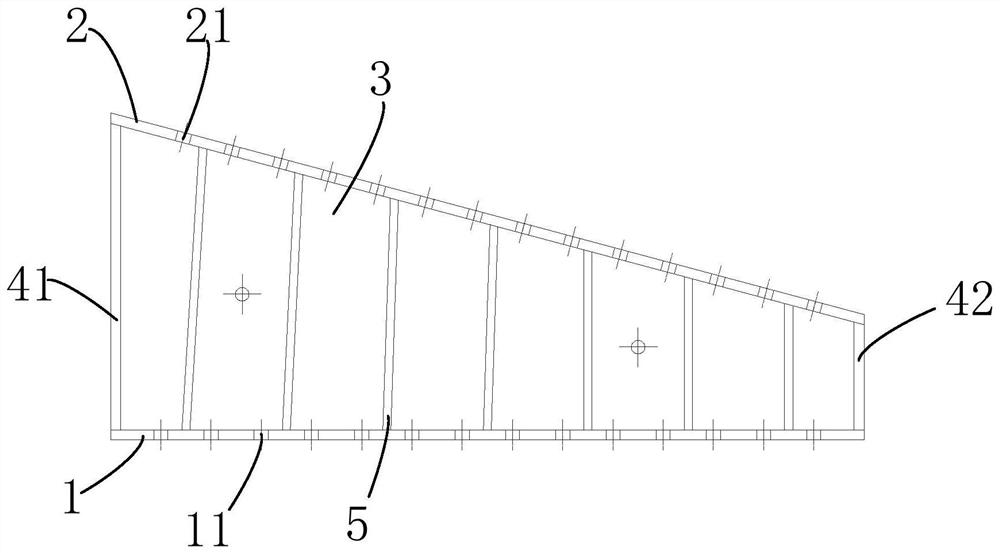

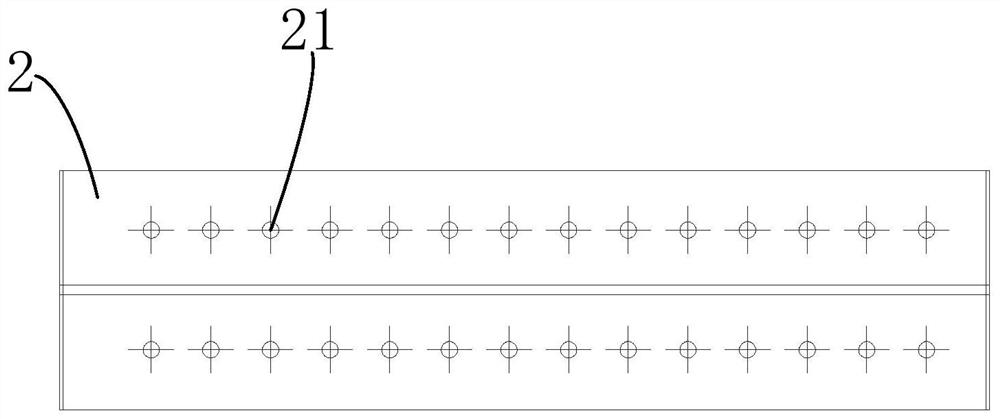

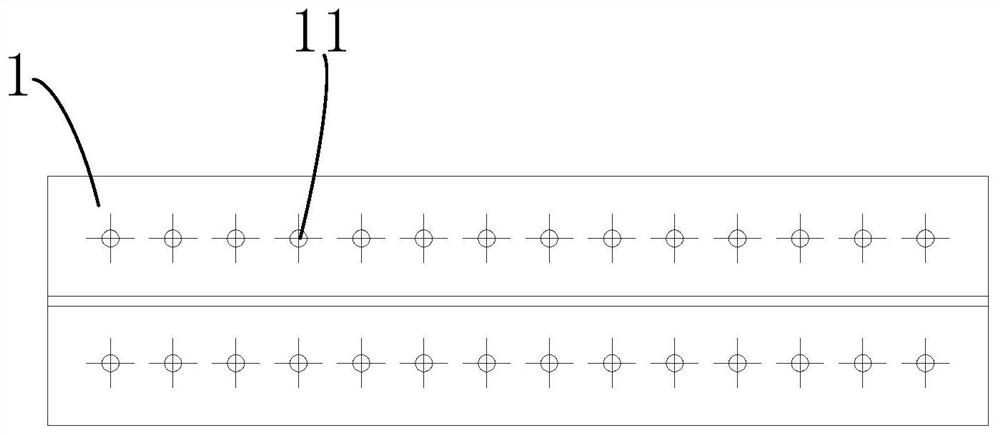

[0031] Please refer to Figure 1 to Figure 6 As shown, it is a diagram of Embodiment 1 of an angle adjustment member for steel support in the present application. The angle adjusting member for steel support includes a bottom flange plate 1, a top flange plate 2 and a web 3, and the bottom flange plate 1, the top flange plate 2 and the web 3 are all steel plates. The bottom flange plate 1 and the top flange plate 2 are opposite to each other, and the web 3 intersects the bottom flange plate 1 and the top flange plate 2 . That is, the web 3 is erected between the bottom flange 1 and the top flange 2 . Preferably, the lower and upper ends of the web 3 are connected to the central axis of the length direction of the bottom flange 1 and the top flange 2, so that the angle adjustment member has a symmetrical structure, ensuring Force balance during use. The web 3 is perpendicular to the bottom flange 1 and the top flange 2 .

[0032] see Figure 4 As shown, the web 3 is a righ...

Embodiment 2

[0037] see Figure 7 As shown, it is a diagram of Embodiment 2 of an angle adjustment member for steel support in the present application. It differs from Embodiment 1 mainly in that the included angle it forms is different from Embodiment 1. In this embodiment, the angle between the top flange plate 2 and the bottom flange plate 1 of the angle adjusting member is 5°. Each component and its structure in this embodiment can be set with reference to Embodiment 1, and will not be repeated here. In another embodiment, the angle formed by the top flange plate 2 and the bottom flange plate 1 of the angle adjusting member may also be 10° or other angles.

Embodiment 3

[0039] see Figure 8 and Figure 9 As shown, it is a diagram of Embodiment 3 of an angle adjustment member for steel support in the present application. The main difference between it and Embodiment 1 and Embodiment 2 is that it also includes an adapter plate 6 .

[0040] Specifically, in this embodiment, the angle adjusting member for steel support further includes an adapter plate 6 . The adapter plate 6 is parallel to the bottom flange plate 1 and welded on the web 3 , and the stiffening plate 5 includes a joint welded between the adapter plate 6 and the bottom flange plate 1 The first stiffening plate 51 between them, and the second stiffening plate 52 welded between the adapter plate 6 and the top flange plate 2 . The first stiffening plate 51 is perpendicular to the bottom flange plate 1 , the adapter plate 6 and the web 3 respectively. The second stiffening plate 52 is perpendicular to the top flange plate 2 and the web 3 , but not perpendicular to the adapter plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com