A dust suppression device for coal mining

A technology for coal mines and placing troughs, applied in safety devices, dust-proofing, mining equipment, etc., can solve the problems of heavy dust suppression workload of operators, inflexible use of dust suppression equipment, high equipment costs, etc. The effect of high dust suppression efficiency and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

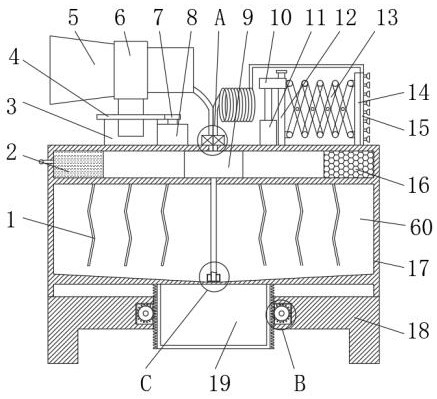

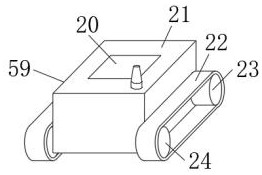

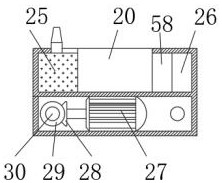

[0036] like Figure 1-12 As shown, the embodiment of the present invention provides a dust suppression device for coal mining, including a base 18 and a crawler 59, a placement slot 19 is provided through the middle of the bottom end of the base 18, and an accommodation slot is provided in the front and rear ends of the placement slot 19. 41. The third servo motor 54 drives the rack 40 to move downward through the third gear 55, so that the placing slot 19 slides down in the base 18. At this time, the accommodating slot 41 in the placing slot 19 moves downward, making the crawler 59 in the Below the base 18 , the racks 40 are fixedly connected to the middle of the two sides of the placement groove 19 , the middle of the front and rear ends of the lower surface of the base 18 is provided with a second groove 34 on both sides, and the inner top of the second groove 34 is fixed. A hydraulic cylinder 31 is connected, and the driving ends of the front and rear hydraulic cylinders 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com