Magnetic liquid sealing device

A magnetic liquid and sealing device technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of magnetic liquid loss, affecting sealing performance, small sealing gap, etc., and achieve the effect of not easy adsorption and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

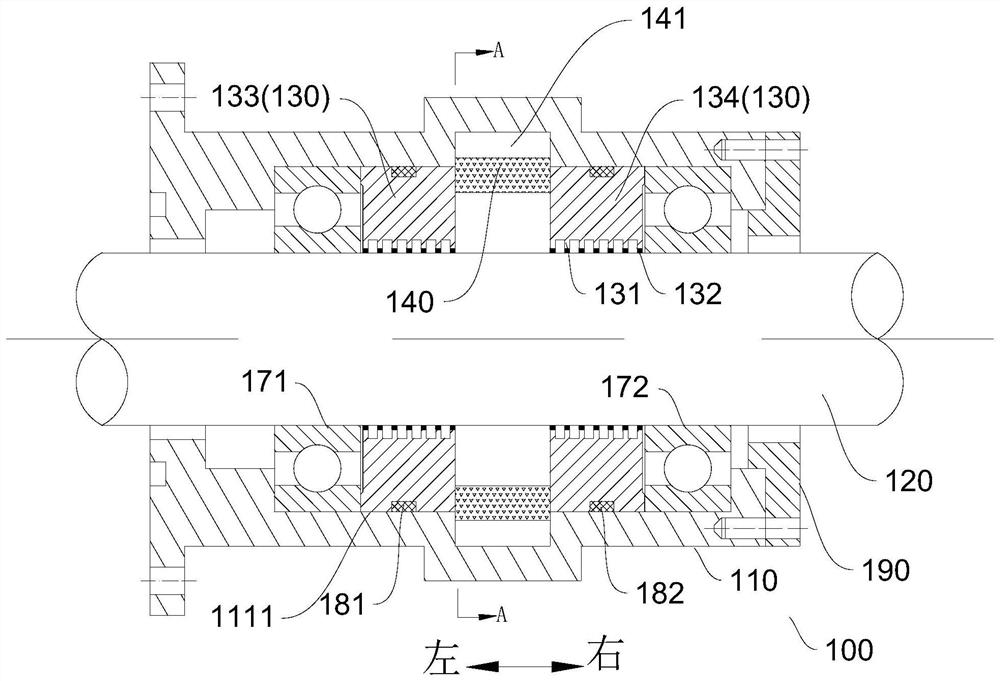

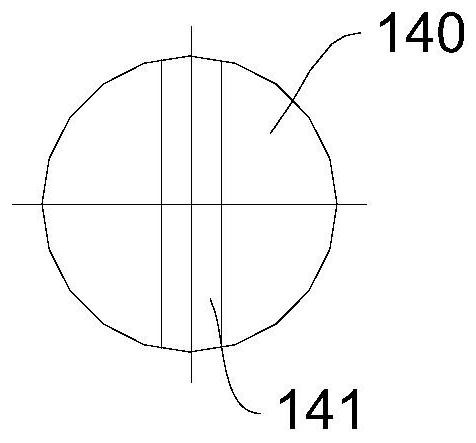

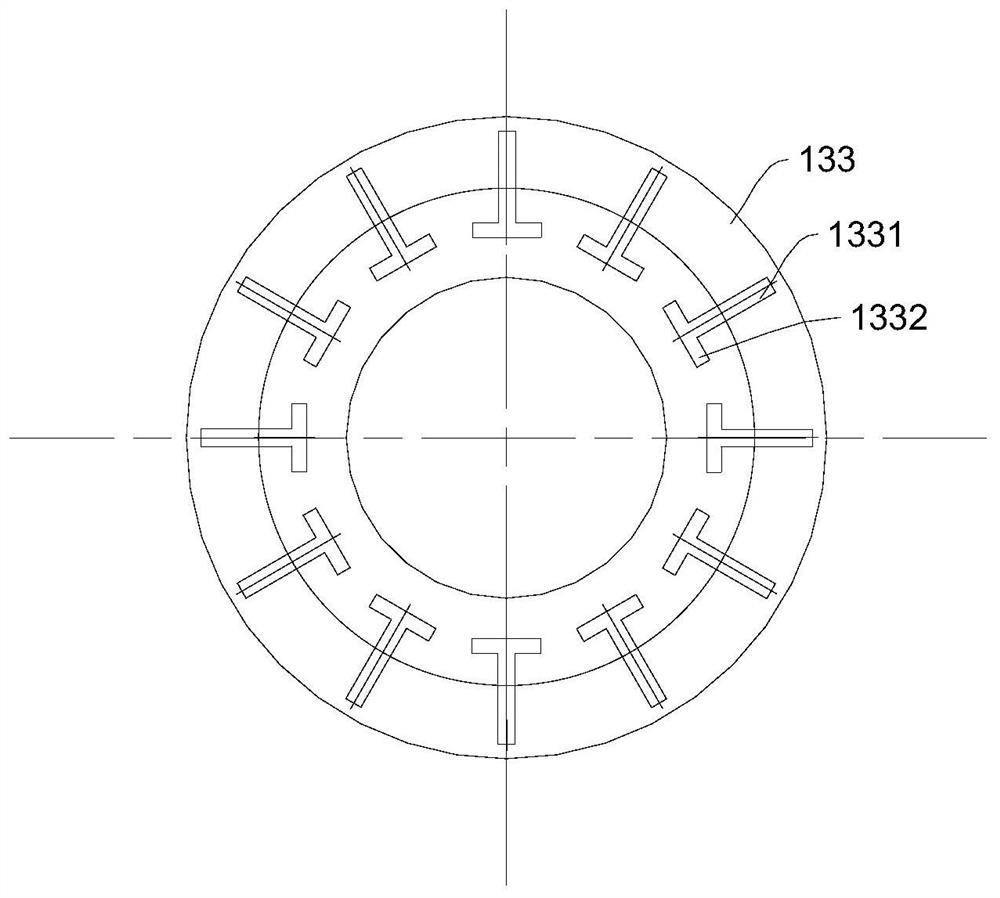

[0046]Such asfigure 1 As shown, the magnetic liquid sealing device 100 in the present embodiment includes a shaft case 110, a rotating shaft 120, a first pole shoe 133, a second pole shore 134, and a permanent magnet group (first permanent magnet group). The first permanent magnet group includes a plurality of permanent magnets 140, and several permanent magnets 140 are arranged around the shaft 120 along the circumferential direction of the shaft 120. In this embodiment, the permanent magnet 140 is a cylindrical shape, the axial direction is the same as the axial direction of the rotating shaft 120. It will be appreciated that in other embodiments, the permanent magnet 140 can be other columnar structures.

[0047]The first pole shoe 133 and the second pole shoe 134 are all set to the shaft 120, and the outer circumferential surface is connected to the peripheral wall surface 1111 of the chamber 111 to be connected to the shaper shell 110. The first permanent magnet group is located b...

Embodiment 2

[0065]The structure of the magnetic liquid sealing device in this embodiment is basically the same as that of the Example, and will be described herein. Different from the circumferential wall surface 1111 formed a plurality of avoidance grooves 112, the plurality of avoidance grooves 112 corresponds to a plurality of permanent magnets 140 in the first permanent magnet group, and the avoidance groove 112 and the diameter of the permanent magnet 140 corresponding to the rotation shaft 120. On the other hand, that is, at least a portion of the permanent magnet 140 can be located within the avoidance groove 112 corresponding thereto. It will be appreciated that the plurality of avoidance grooves 112 are arranged around the circumferential direction of the rotating shaft 120 on the circumferential wall surface 1111. Alternatively, in other embodiments, a plurality of avoidance grooves 112 around the circumferential arrangement around the shaft 120 are formed, each of which corresponds t...

Embodiment 3

[0068]The structure of the magnetic liquid sealing device in this embodiment is basically the same as that of the Example, and will be described herein. Different, such asFigure 4 As shown, the shaft case 110 in the present embodiment includes a first sub-axle housing 113 and a second sub-axle shell 114. The first sub-axle housing 113 and the second sub-axle housing 114 are arranged in the axial direction of the shaft 120 and detachably interconnected. The first sub-axle housing 113 and the second sub-axle housing 114 collectively define the chamber 111 and the avoidance tank 112. Alternatively, the first sub-axle housing 113 and the second sub-axle case 114 are connected by a connection bolt 160.

[0069]The first pole shoe 133 is located within the subcarcies formed by the first sub-axis casing 113, and the second pole shoe 134 is located in the sub-chamber formed by the second sub-axle housing 114. The left end of the permanent magnet 140 extends into the first sub-axle case 113, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com