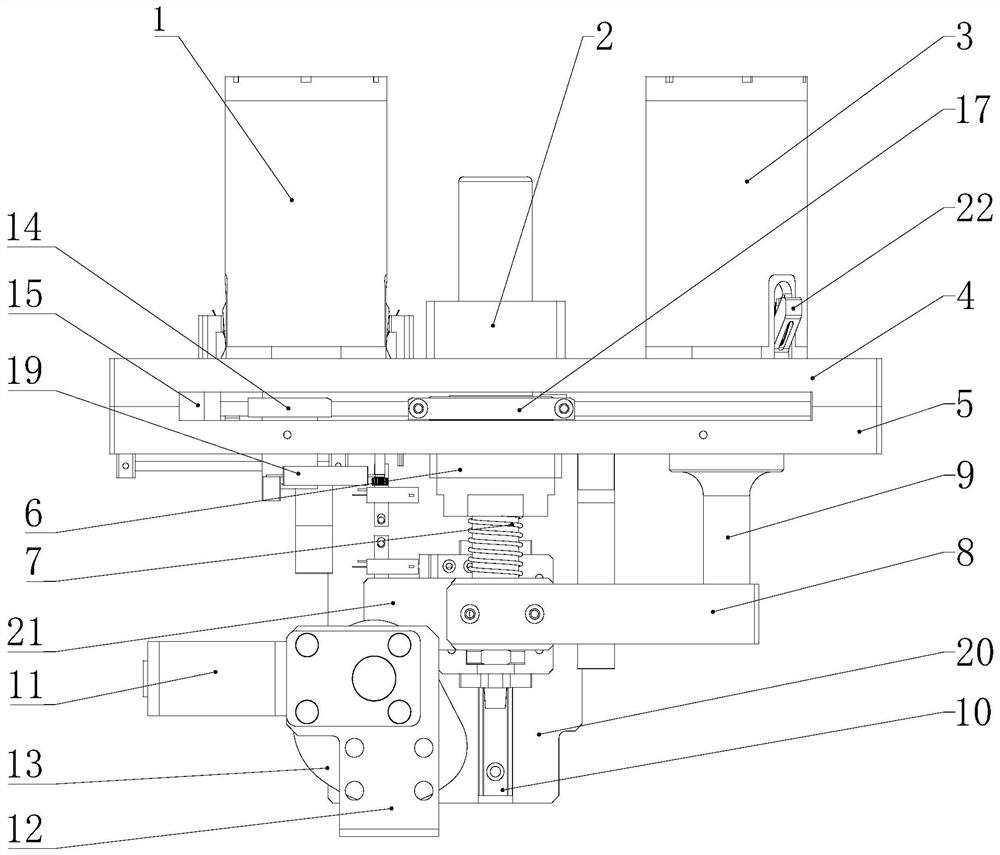

Automatic film changing device of particulate matter sampler

A technology of automatic membrane change and sampler, which is applied in the field of particle sampler and air detection, which can solve the problems of troublesome operation and inconvenient time measurement, so as to achieve the effect of not easy to drop, improve sampling efficiency and sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

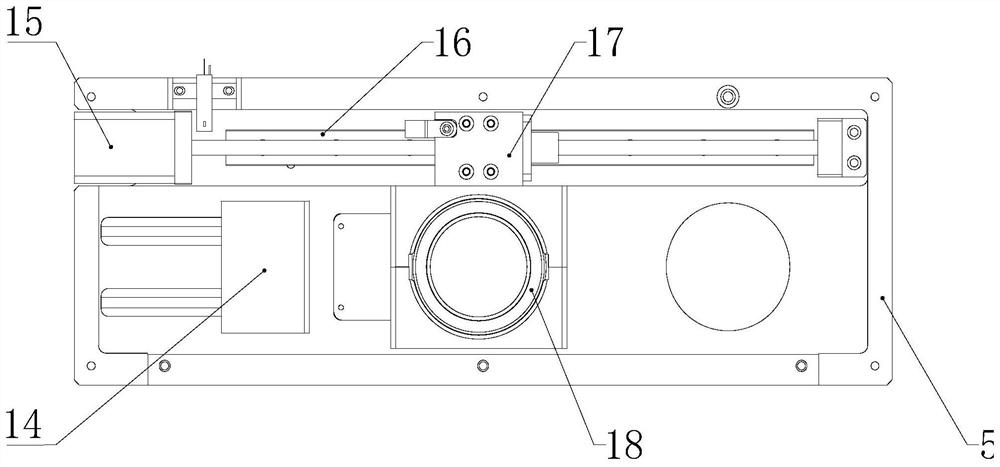

[0015] refer to figure 1 , figure 2 , an automatic membrane changing device for a particle sampler of the present invention, comprising a blank membrane cylinder 1, an upper membrane opening 2, a sampling membrane cylinder 3, a chute upper plate 4, a chute lower plate 5, a lower membrane opening 6, a compression spring 7, Top membrane support 8, top membrane rod 9, first guide rail 10, DC motor 11, motor seat 12, automatic cam 13, anti-off slide plate 14, screw motor 15, second guide rail 16, push plate 17, filter membrane holder 18. Tension spring 19, back seat plate 20, cam plate 21, check film buckle 22, the back seat plate 20 is fixed with a chute upper plate 4 and a chute lower plate 5, and the upper end of the chute upper plate 4 is sequentially A blank membrane tube 1, an upper membrane port 2, and a sampling membrane tube 3 are installed, and several filter membrane clips 18 are arranged in the blank membrane tube 1, and a chute is formed between the upper plate 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com