Ultrasonic in-situ automatic detection system for creep cracks on inner wall of hydrogen production furnace tube

An ultrasonic system and automatic detection technology, applied in the signal transmission system, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems that do not involve multi-channel ultrasonic transducer transmission detection methods , cables affect the detection distance, manually change the detection position, etc., to solve the problem of automatic detection in situ, increase the burden of movement, and reduce the complexity of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

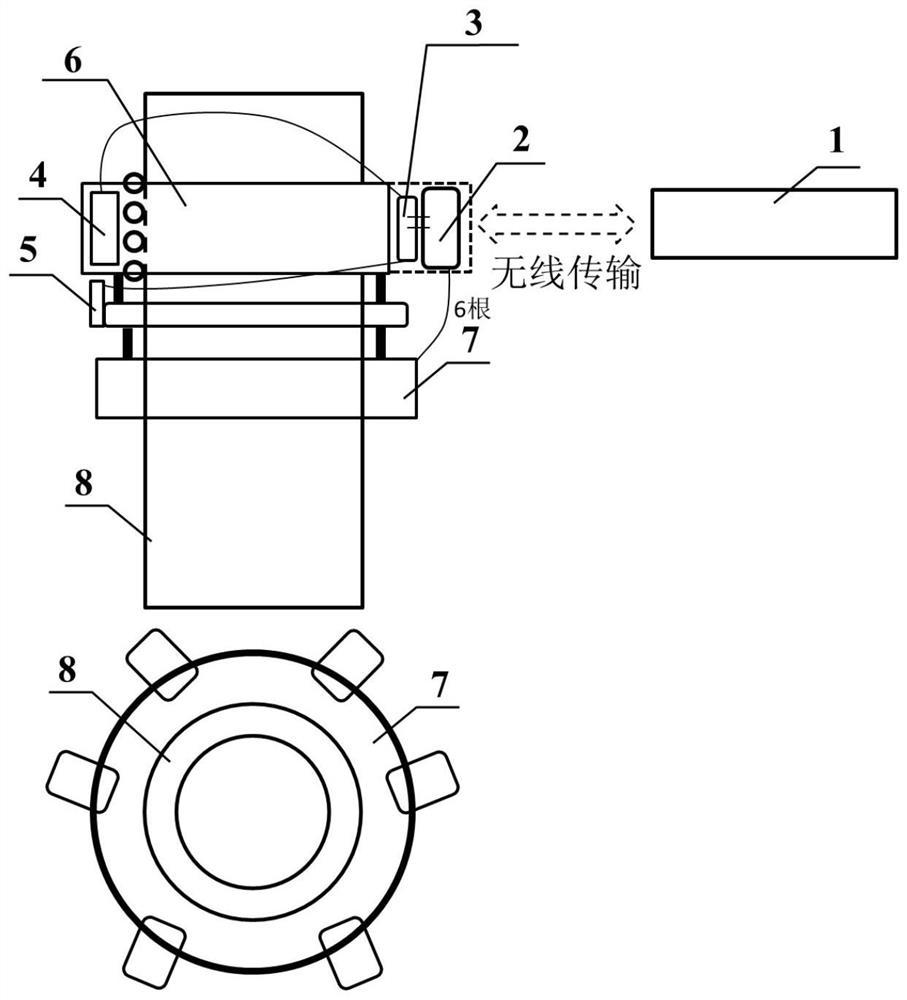

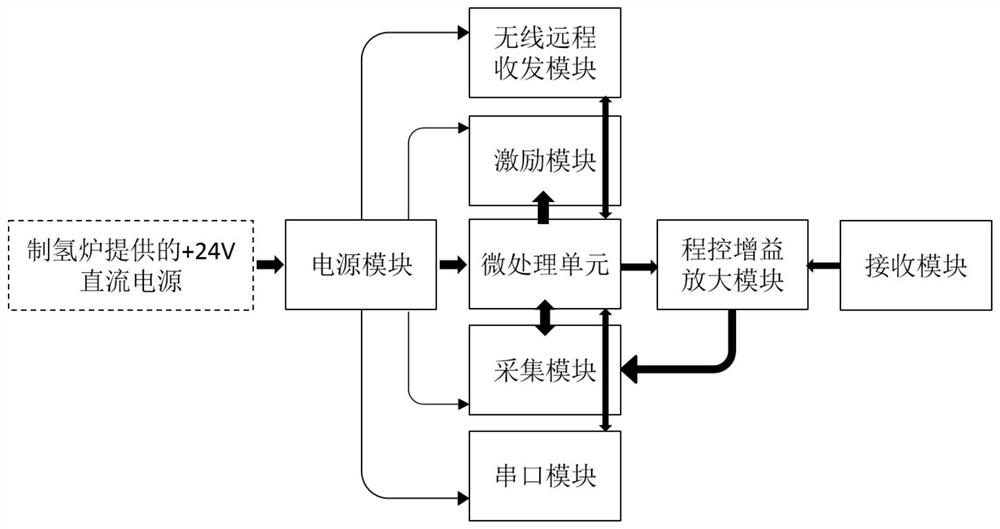

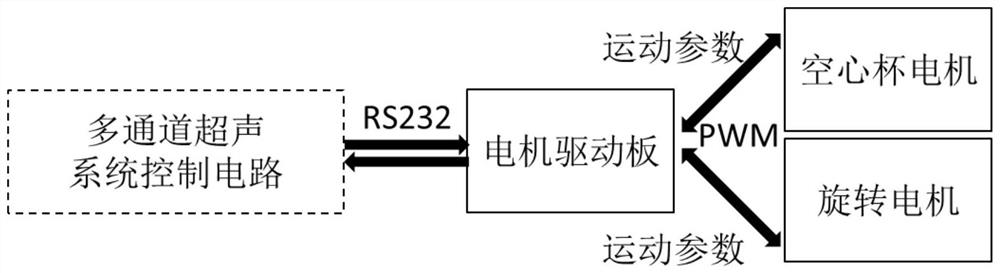

[0032] The ultrasonic in-situ automatic detection system for creep cracks in the hydrogen production furnace tube of the present invention will be further described below in conjunction with the accompanying drawings and examples. The structural schematic diagram of the ultrasonic in-situ automatic detection system for creep cracks on the inner wall of the hydrogen production furnace tube used in this example is as follows figure 1 As shown, in order to cover the entire circumference of the furnace tube, the number of piezoelectric transducers required by the test is 6, one excitation and one collection are divided into 3 groups of two each, and the excitation on the multi-channel ultrasonic system control circuit The receiving SMA head is correspondingly connected to the piezoelectric transducer.

[0033] Such as figure 1As shown, a hydrogen production furnace tube creep crack ultrasonic in-situ automatic detection system according to the present invention includes a compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com