Fire-proof and flame-retardant cable and wrapping mechanism for producing fire-proof and flame-retardant cable

A fire-retardant and wrapping technology, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of poor flame-retardant and fire-proof performance, and the wrapping mechanism cannot be provided, so as to reduce the time for replacing paper trays and improve Production efficiency and the effect of extending the continuous use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0040] It should be noted that the words "front", "rear", "left", "right", "upper", "lower", "bottom" and "top" used in the following description refer to the attached In the directions in the drawings, the words "inner" and "outer" refer to directions toward or away from the geometric center of a particular component, respectively.

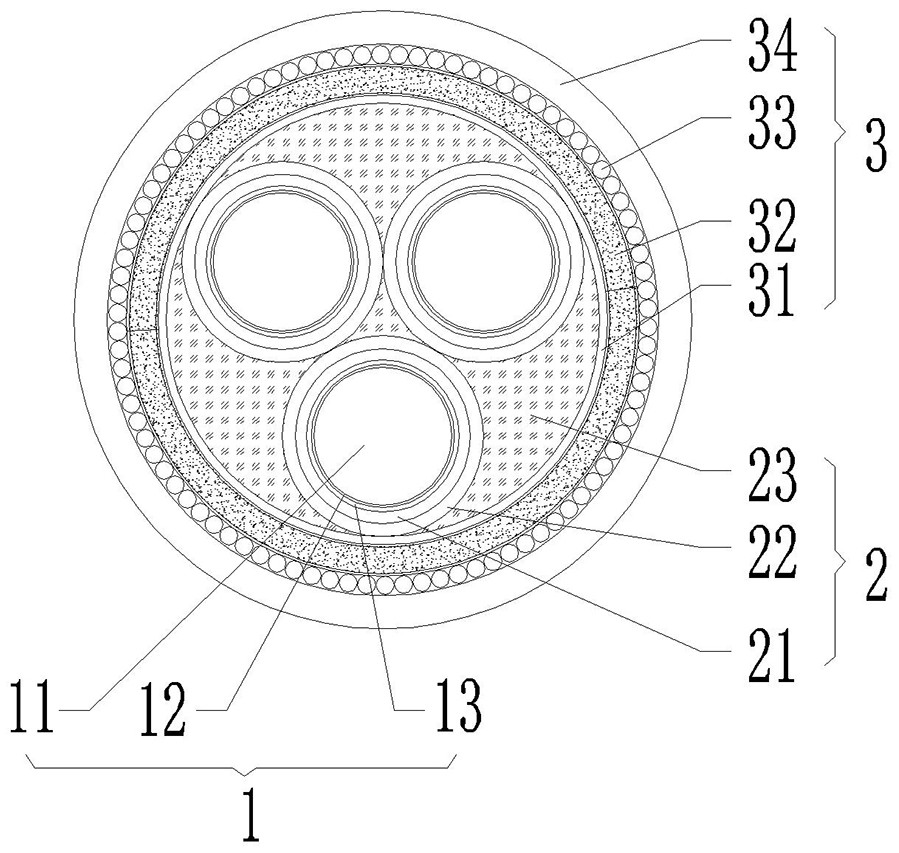

[0041] like Figure 1 to Figure 7 As shown, a fire-resistant and flame-retardant cable includes a plurality of inner cores 1, and each inner core 1 includes a wire core 11, an insulating layer 12 and a shielding layer 13 from the inside to the outside, and also includes an inner protective layer 2 and an outer protective layer 3;

[0042] The inner protective layer 2 includes a flame-retardant layer 21, a fire-proof layer 22 and a filling layer 23, and the flame-retardant layer 21 and the fire-proof layer 22 are layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com