Automobile wire harness fixing support

A technology for fixing brackets and automotive wiring harnesses, applied in electrical components and other directions, which can solve the problems of easy shaking, large occupied space, long wiring harness length, etc., and achieve the effect of reducing abnormal noise, reducing wiring harness cost, and optimizing wiring harness length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

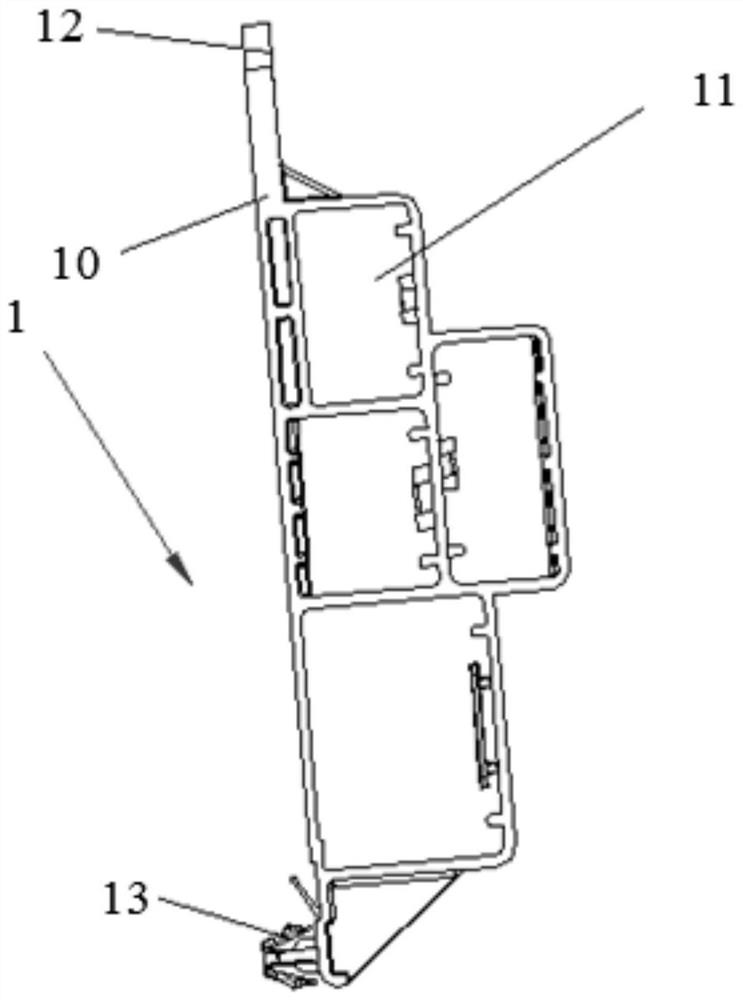

[0019] The automobile wire harness fixing bracket of the present invention includes a bracket main body 1. The bracket main body 1 includes a flat plate portion 10 and a frame mouth portion 11 located above the flat plate portion 10. There are four frame mouth portions 11 in total, including the Three arranged along the length direction of the flat plate parts 10 and a fourth one located above the three frame mouth parts. A screw hole 12 is formed at one end of the two ends along the length direction of the flat plate portion 10 , and a fixing buckle 13 is formed at the other end. The fixing buckle 13 is formed on a side wall of the flat plate portion 10 opposite to the frame mouth portion 11 .

[0020] In this embodiment, the screw holes 12 and the fixing buckles 13 are located on both sides of the periphery of the frame opening 11 .

[0021] In order to increase the overall strength of the entire automobile wire harness fixing bracket, a reinforcing rib 13 is formed between...

Embodiment 2

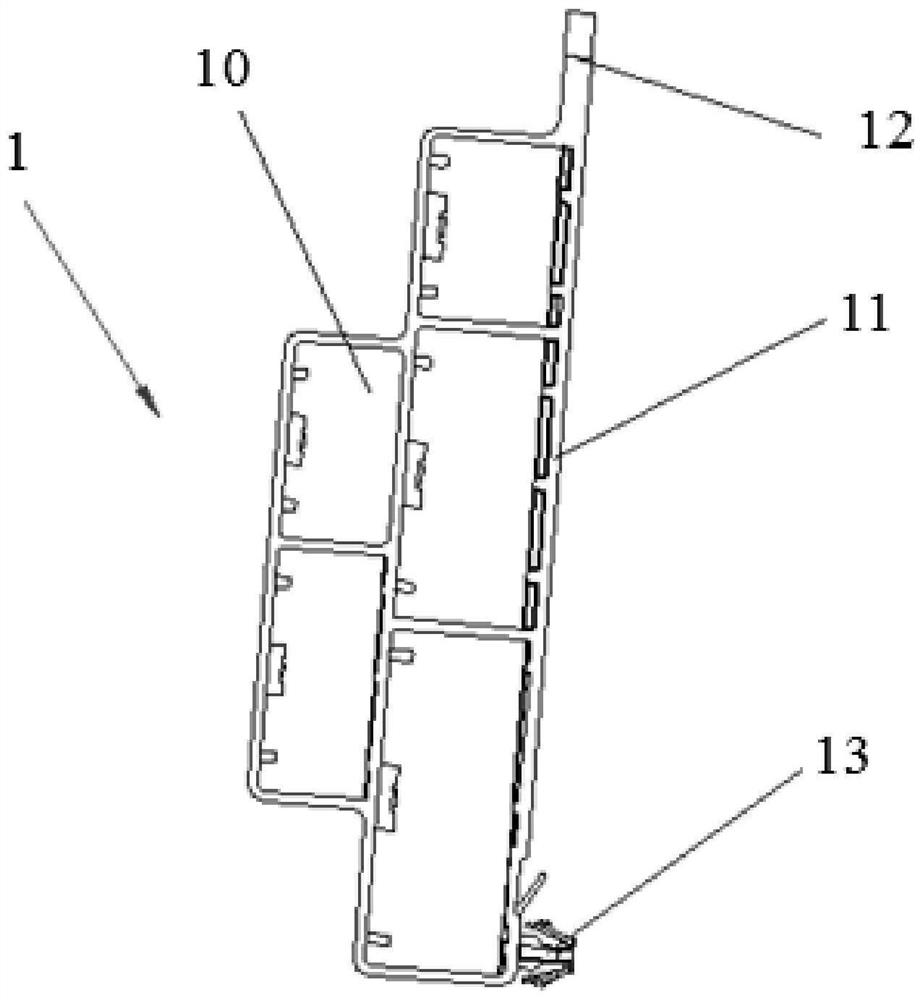

[0023] The automobile wiring harness fixing bracket of the present invention includes a bracket main body 1. The bracket main body 1 includes a flat plate portion 10 and a frame mouth portion 11 located above the flat plate portion 10. There are five frame mouth portions 11 in total, including the Three arranged along the length direction of the flat plate parts 10 and the fourth and fifth ones located above the three frame mouth parts. A screw hole 12 is formed at one end of the two ends along the length direction of the flat plate portion 10 , and a fixing buckle 13 is formed at the other end. The fixing buckle 13 is formed on a side wall of the flat plate portion 10 opposite to the frame mouth portion 11 .

[0024] In this embodiment, the screw holes 12 are located on the peripheral side of the frame opening 11 , and the fixing buckles 13 are located on the opposite side wall of the frame opening 11 .

[0025] In the automobile wiring harness fixing bracket of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com