Material mixing and fermenting device for edible mushroom production

A fermentation device and material mixing technology are applied in the field of material mixing and fermentation devices for edible fungi production, which can solve the problems of incapable of sterilizing materials and reduce the production safety of edible fungi, so as to increase the fermentation effect, improve the temperature control effect, and ensure safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

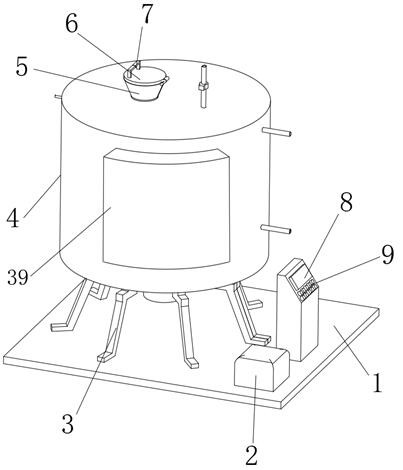

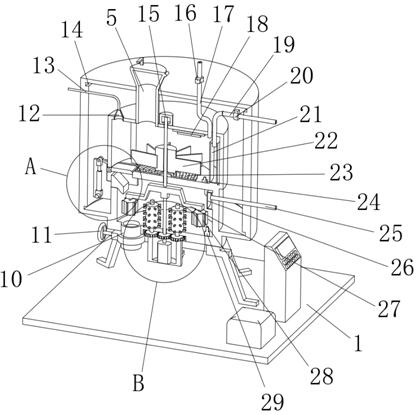

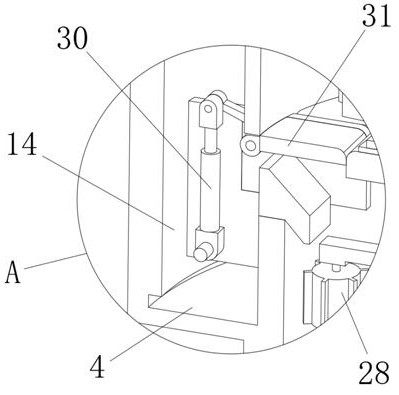

[0034] refer to Figure 1-Figure 6, a material mixing fermentation device for edible fungus production, comprising a bottom plate 1, a plurality of support legs 3 are fixed on the upper surface of the bottom plate 1 by bolts, a tank body 4 is fixed on the top of the support legs 3 by bolts, and the support legs 3 are on the tank body 4 plays a supporting role, the top of the tank body 4 is sealed and plugged with a feed pipe 5, the bottom inner wall of the tank body 4 is fixed with a fermenter by bolts, the fermenter is connected with the feed pipe 5, and the material passes through the feed pipe 5 Enter the fermentation tank, the interior of the fermentation tank is provided with an upper fermentation chamber and a lower fermentation chamber, and the top of the fermentation tank is sealed and inserted with an air inlet pipe 17, one end of the air inlet pipe 17 passes through the tank body 4, and the bottom of the upper fermentation chamber is passed through bolts respectively....

Embodiment 2

[0042] refer to Figure 7 The difference between embodiment 2 and embodiment 1 is that: the mixed fermentation device includes a mixing box 36 fixed on the top inner wall of the tank body 4 by bolts, and a mixing wheel 37 is connected to one side inner wall of the mixing box 36 in rotation, and The inlet pipe 17 is plugged into the mixing box 36, and the design of the inlet pipe 17 and the water inlet pipe 19 being in the mixing box 36 simultaneously can make oxygen and water enter the fermenter simultaneously during fermentation, and flow into the fermenter, increasing the Fermentation effect, the bottom of the mixing box 36 is sealed and inserted with a connecting pipe 38, and one end of the connecting pipe 38 communicates with the ventilating cylinder 21.

[0043] The working principle of this embodiment: when in use, first make oxygen and water enter the mixing tank 36 at the same time, and under the impact of water, the mixing wheel 37 rotates, so that the oxygen and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com