Bridge guardrail

A technology for guardrails and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of guardrails with little protection, too simple functions, and lack of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

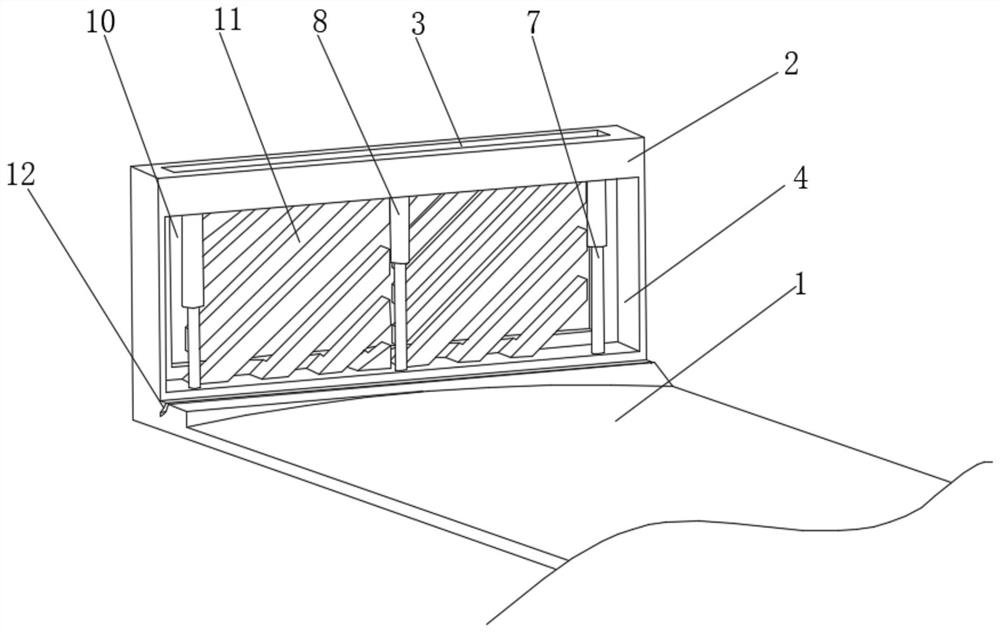

[0030] see figure 1 , the present invention provides a technical solution: a bridge guardrail, including a bridge base surface 1, the outer surface of the bridge base surface 1 is fixedly connected with a protective pile 2, the top of the protective pile 2 is provided with a greening groove 3, and the outer surface of the protective pile 2 On the surface and below the greening groove 3, there is a through groove 4, the top and bottom of the inner surface of the through groove 4 are provided with a curved groove 5, and the inner surface of the curved groove 5 is provided with an elastic mechanism 6, two curved grooves 5 The opposite sides are evenly slidably connected with a curved rod 7, the outer surface of the curved rod 7 is fixedly connected with an anti-collision mechanism 8, and the outer surface of the curved rod 7 is movably connected with the inner surface of the curved groove 5. The buffer mechanism 9, the inner surface of the through groove 4 and is located directly...

Embodiment 2

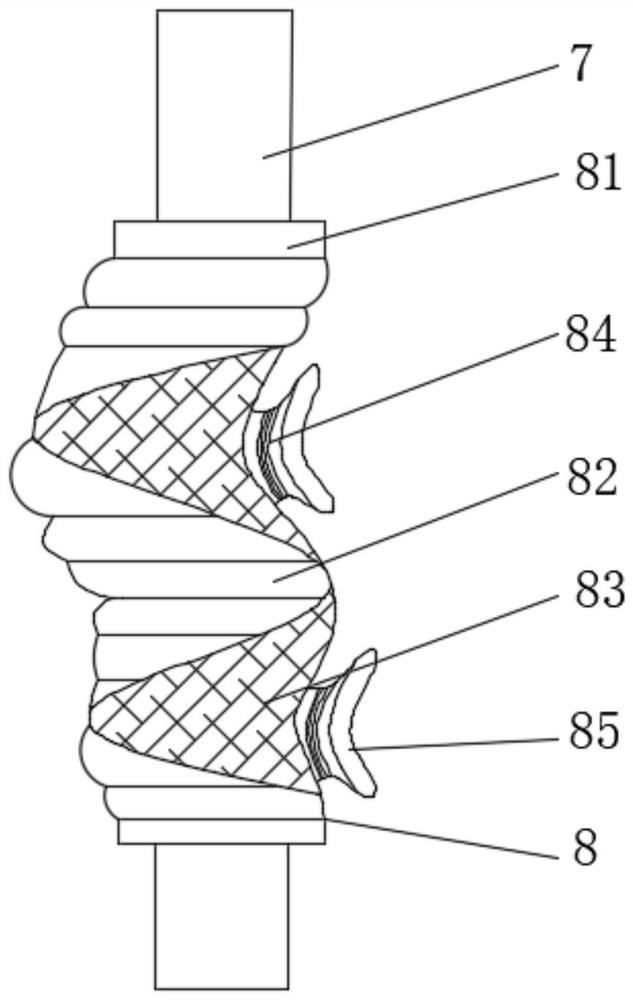

[0032] see figure 2, the present invention provides a technical solution: the anti-collision mechanism 8 includes a shock absorbing sleeve 81, the outer surface of the shock absorbing sleeve 81 is fixedly connected with the outer surface of the curved rod 7, and the outer surface of the shock absorbing sleeve 81 is wound and connected with The anti-collision rubber strip 82, the outer surface of the shock-absorbing sleeve 81 and the top and bottom of the anti-collision rubber strip 82 are wound and connected with a shock-absorbing pad 83, and the outer surface of the shock-absorbing pad 83 is fixedly connected with a spring leaf 84, and the spring leaf The outer surface of 84 is fixedly connected with a sliding piece 85, and the outer surface of the sliding piece 85 is a curved surface. By wrapping the anti-collision rubber strip 82 and the shock pad 83 on the outside of the shock-absorbing sleeve 81 , the impact force of the vehicle can be dispersed after the outside of the ...

Embodiment 3

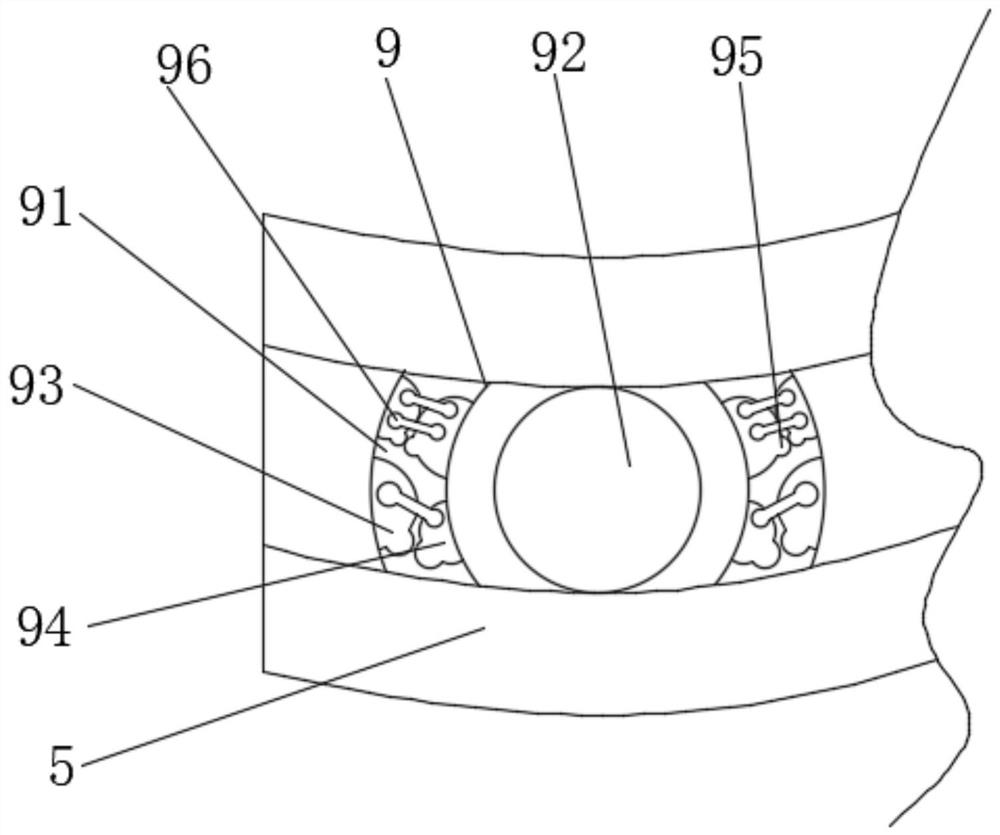

[0034] see image 3 , the present invention provides a technical solution: the buffer mechanism 9 includes a buffer casing 91, the outer surface of the buffer casing 91 is movably connected with the inner surface of the curved groove 5, and a circular groove 92 is provided at the center of the buffer casing 91. The inner surface of the groove 92 is movably connected with the outer surface of the curved rod 7 , and the inner surface of the buffer casing 91 is evenly and fixedly connected with a first buffer hemisphere 93 . When the curved rod 7 is subjected to an impact force, the fixed connection can be changed to shake left and right in a small range, which gives the curved rod 7 the effect of buffering force, and the first buffer hemisphere 93 and the second buffer hemisphere 94 arranged inside collide with each other , can avoid the curved rod 7 from shaking too much, and has a limited effect, which improves the flexibility and service life of the protective pile 2 internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com