Automobile door cover durability test device and system

A technology for testing devices and door covers, which is applied in the direction of measuring devices, vehicle testing, and mechanical parts testing, etc., and can solve the problems of single function, high cost, and high overall cost of the split structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

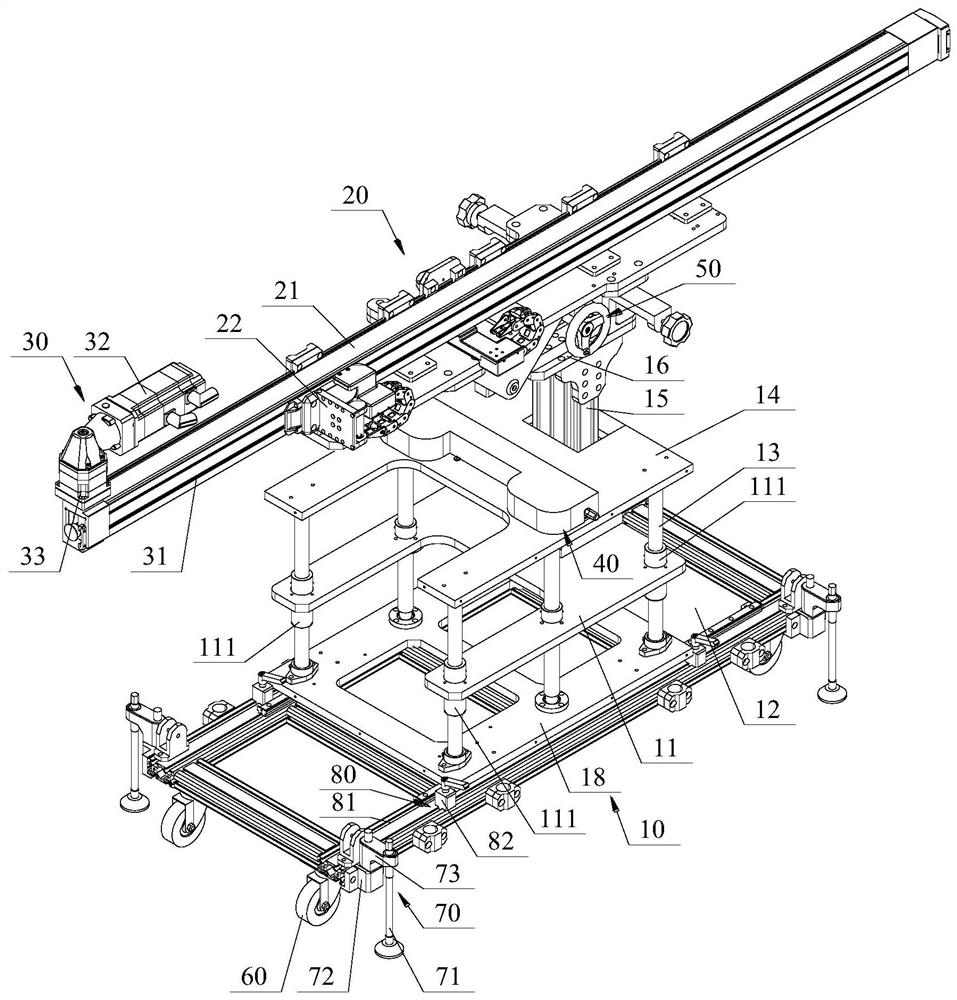

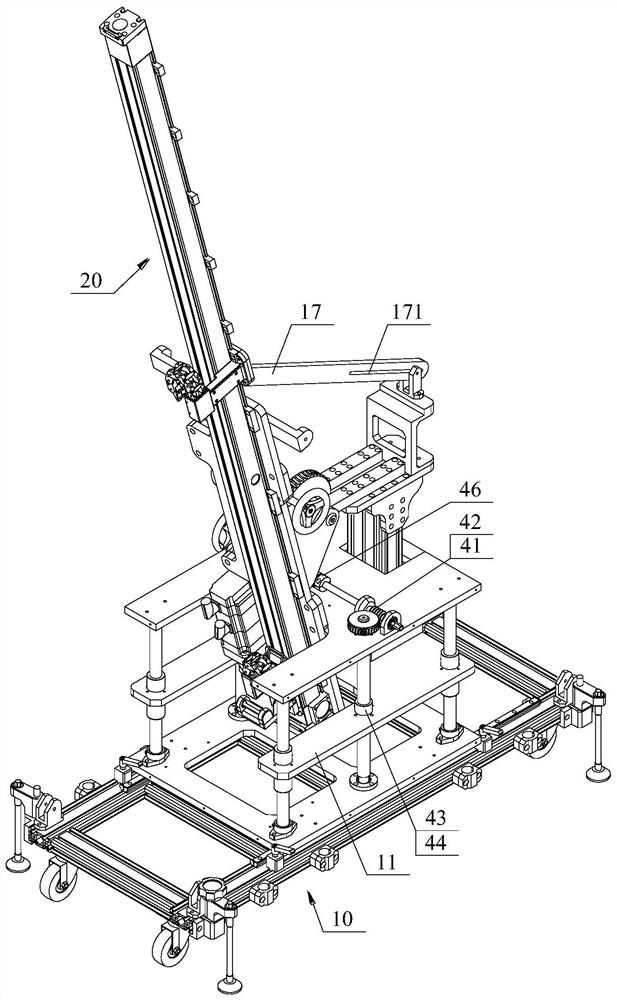

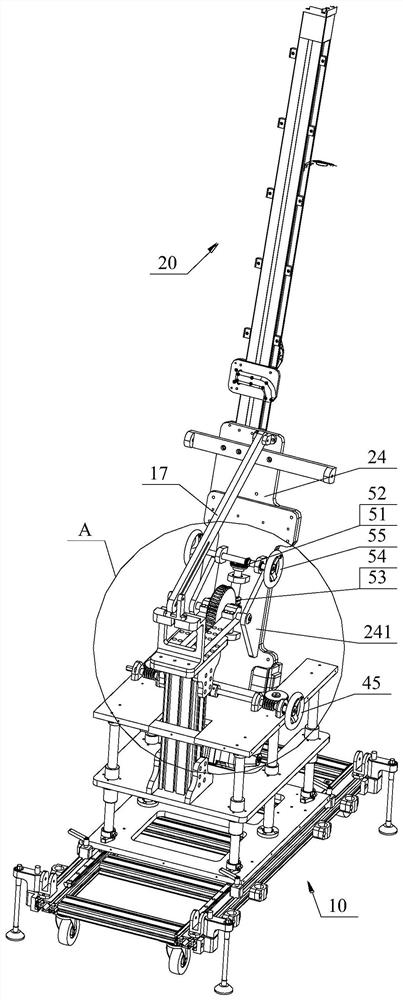

[0035] See figure 1 , which shows a schematic diagram of the overall structure of the automobile door cover durability test device according to this embodiment.

[0036] The automobile door cover durability test device includes a base 10 as a bearing base and a slide assembly 20 arranged on the base 10 . As shown in the figure, the base 10 has a lifting platform 11, and the lifting platform 11 can be displaced in the height direction relative to the base 12 of the base 10; specifically, the lifting platform can be adjusted under the action of the first adjustment mechanism 30 11 height positions.

[0037] Wherein, the sliding table assembly 20 can be rotated around the first hinge center line arranged along the left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com