A method for predicting viscosity properties of cellulose bioinks

A technology of bio-ink and characteristic prediction, applied in genetic rules, special data processing applications, design optimization/simulation, etc., can solve problems such as inability to use linear fitting methods, inaccurate prediction results, lack of model comparison and selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the following embodiments do not limit the present invention by any means.

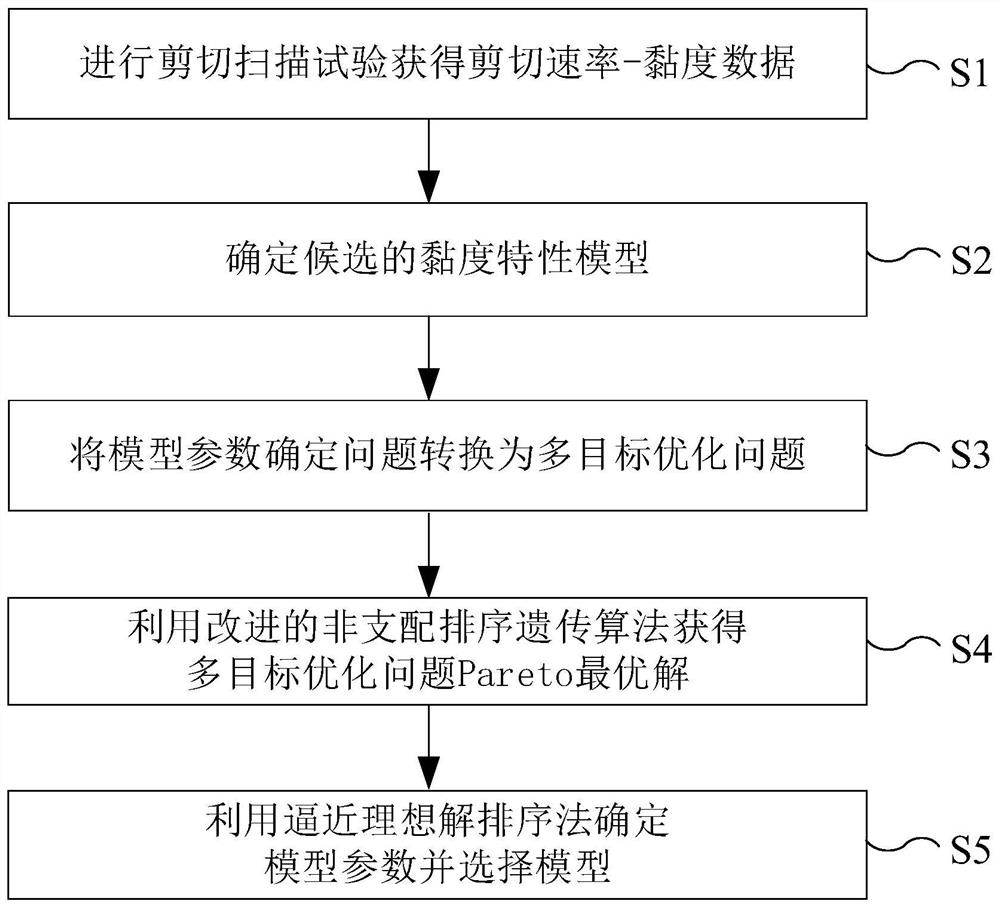

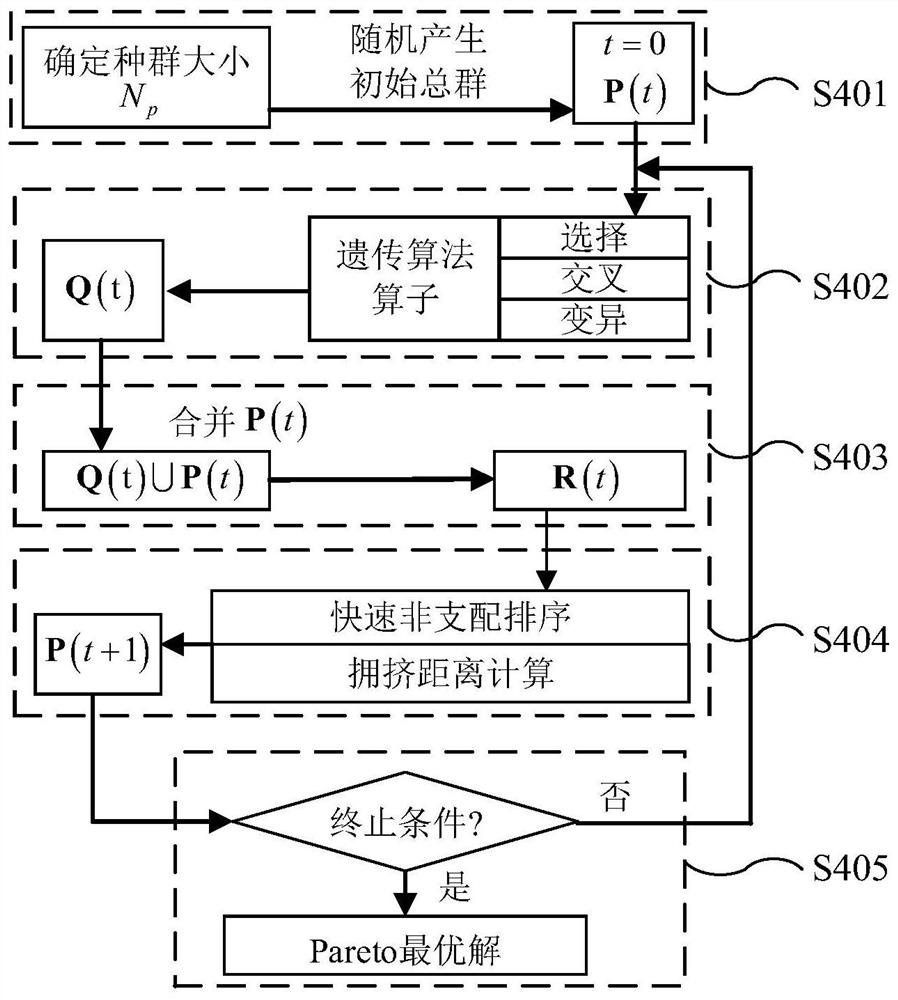

[0082] like figure 1 As shown in the figure, taking the prediction of the viscosity characteristics of a cellulose bio-ink as an example, the specific implementation steps of the method for predicting the viscosity characteristics of a cellulose bio-ink of the present application are described, and the steps are as follows:

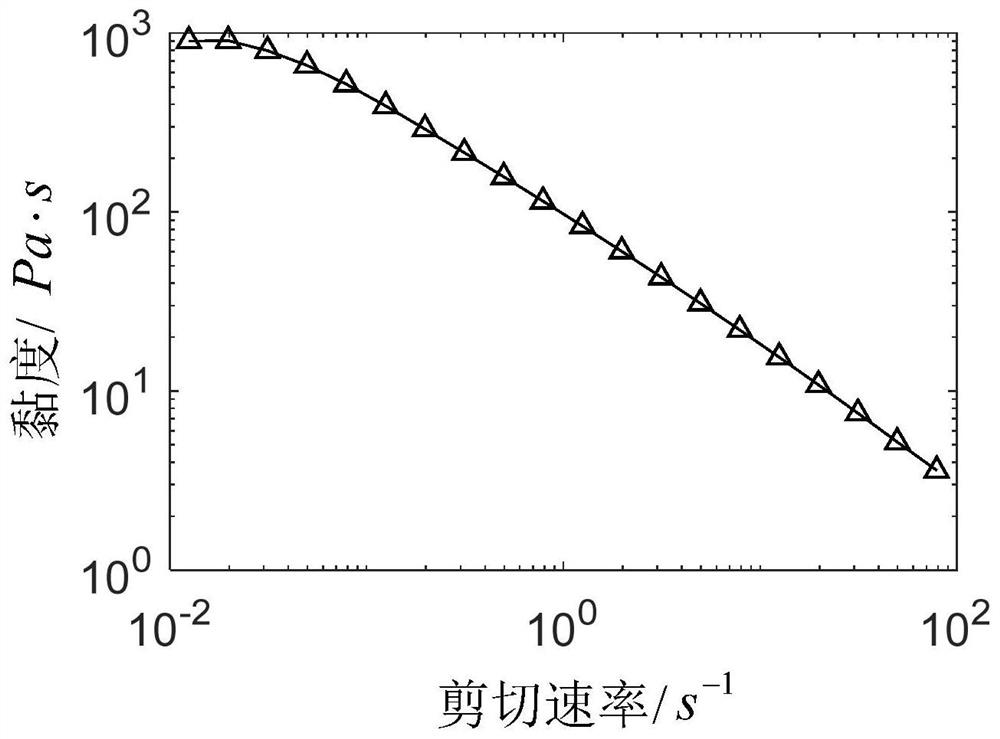

[0083] S1. Use a rotational rheometer to perform a shear scanning test on the cellulose bioink to obtain shear rate-viscosity data; specifically,

[0084] In this step, the rotational rheometer adopts the rotational rheometer ARES (Texas Instruments, USA), and selects two circular plate structures with a diameter of 25 mm as the geometric structure for the viscosity characteristic test, and sets two circular plates arranged in parallel. The spaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com