Method for predicting viscosity characteristics of cellulose bio-ink

A bio-ink and characteristic prediction technology, applied in the fields of genetic laws, special data processing applications, design optimization/simulation, etc., can solve problems such as lack of model comparison and selection, inability to use linear fitting methods, and lack of viscosity models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

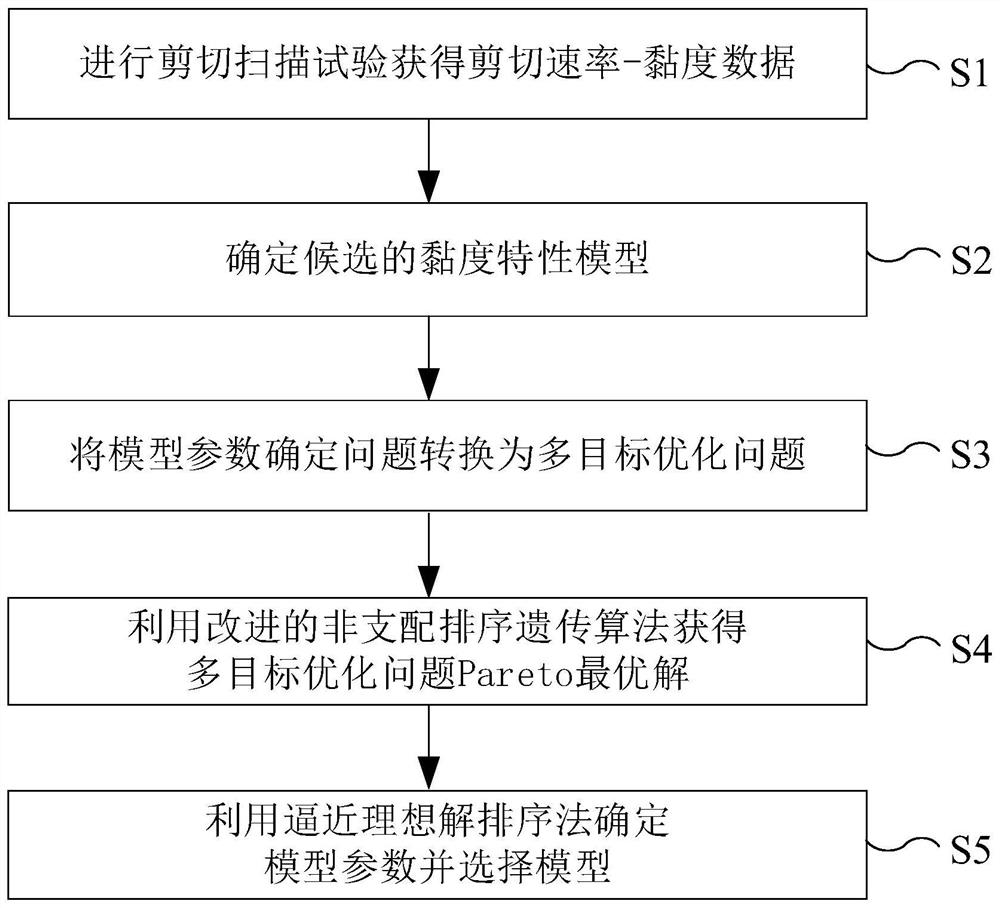

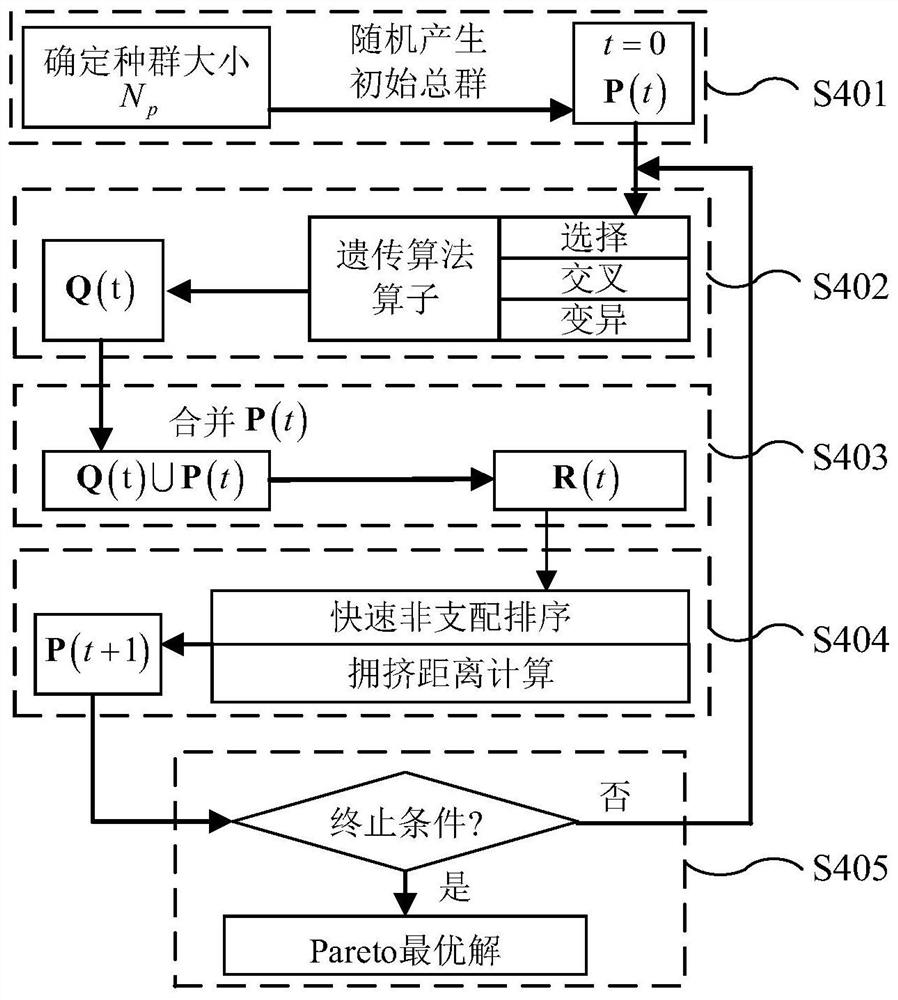

[0082] Such as figure 1 As shown, the viscosity characteristic prediction of a cellulose bioink is taken as an example, and the specific implementation steps of the method for predicting the viscosity characteristics of the cellulose bioink of the present application are described. The steps are as follows:

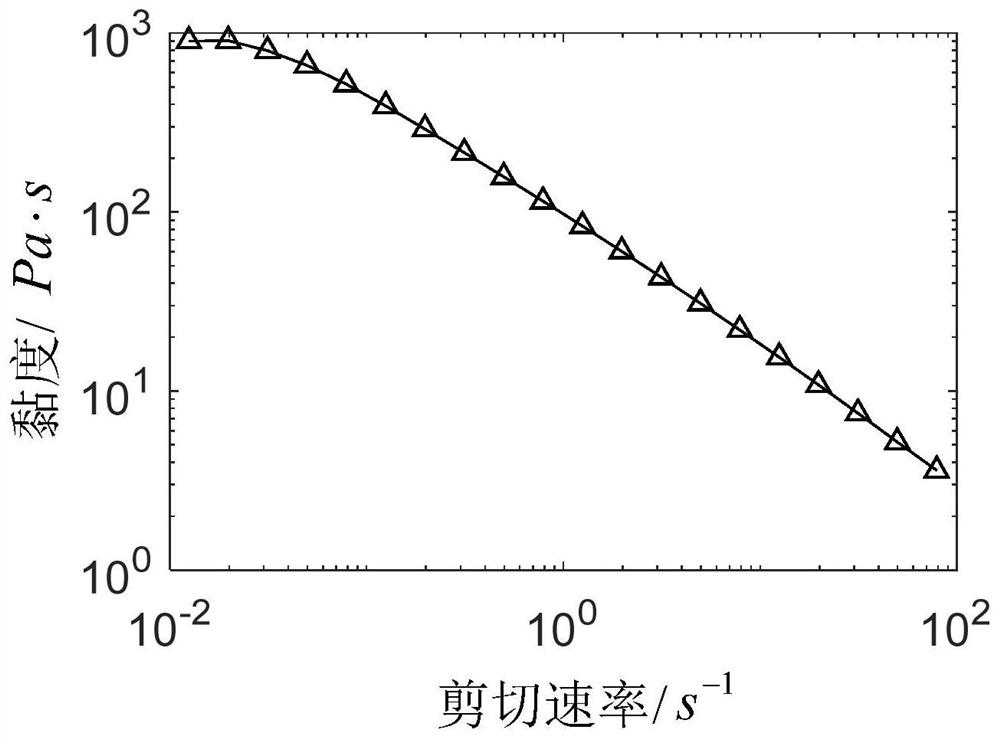

[0083] S1. Using a rotational rheometer to perform a shear scanning test on the cellulose bioink to obtain shear rate-viscosity data; specifically,

[0084] In this step, the rotational rheometer adopts the rotational rheometer ARES (Texas Instruments, USA), and selects two circular flat plates with a diameter of 25mm as the geometric structure for the viscosity characteristic test, and sets two circular flat plates arranged in parallel. Set the distance between the plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com