Single-sided composite aluminum foil belt conveying mechanism for symmetrical cable taping machine

一种复合铝箔、对称电缆的技术,应用在电缆/导体制造、导体/电缆供给装置、电路等方向,能够解决成本高、耗能大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

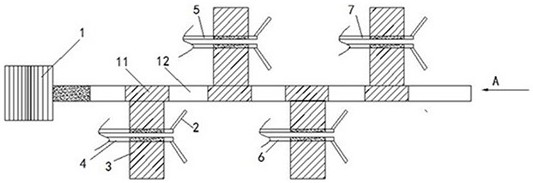

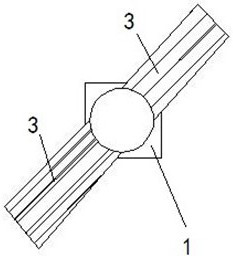

[0029] Such as figure 1 , 2 , 3, an energy-saving taping machine for symmetrical cables, including a frame and a motor 1 arranged on the frame, the output end of the motor 1 drives four tape reels 2 for winding cables , the output end of the motor 1 is provided with a clutch device for controlling the linkage between the motor 1 and the four taping reels 2 . When one motor 1 drives four tape reels 2 to rotate, through the clutch device, respectively control the rotation of the tape reels 2 and the linkage between the tape reels 2 and the clutches are realized.

[0030] Specifically, the output end of the motor 1 is composed of a gear-shaped rotating shaft 11 and a cylindrical rotating shaft 12 alternately, that is, a plurality of gear-shaped rotating shafts 11 are separated by a cylindrical rotating shaft 12, and the gear-shaped rotating shaft 11 drives the gear 3 to move, and the cylindrical rotating shaft The shape rotating shaft 12 is mainly used to separate a plurality o...

Embodiment 2

[0035] Such as Figure 4 As shown, an energy-saving tape machine for symmetrical cables includes a frame and a motor 1 arranged on the frame, and the output end of the motor 1 drives four tape reels 2 for winding cables. The output end of the motor 1 is provided with a clutch device for controlling the linkage between the motor 1 and the four taping reels 2 . When one motor 1 drives four tape reels 2 to rotate, through the clutch device, respectively control the rotation of the tape reels 2 and the linkage between the tape reels 2 and the clutches are realized.

[0036]Specifically, the output end of the motor 1 is composed of a gear-shaped rotating shaft 11 and a cylindrical rotating shaft 12 alternately, that is, a plurality of gear-shaped rotating shafts 11 are separated by a cylindrical rotating shaft 12, and the gear-shaped rotating shaft 11 drives the gear 3 to move, and the cylindrical rotating shaft The shape rotating shaft 12 is mainly used to separate a plurality of...

Embodiment 3

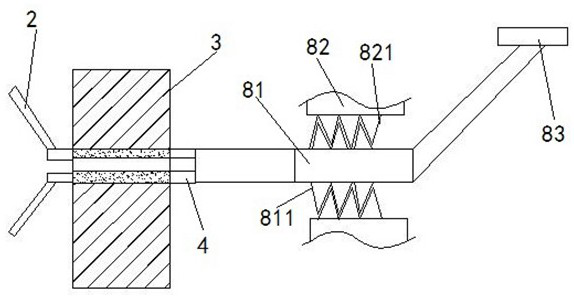

[0039] Such as Figure 5 , 6 As shown, an energy-saving tape machine for symmetrical cables includes a frame and a motor 1 arranged on the frame, and the output end of the motor 1 drives four tape reels 2 for winding cables. The output end of the motor 1 is provided with a clutch device for controlling the linkage between the motor 1 and the four taping reels 2 . When one motor 1 drives four tape reels 2 to rotate, through the clutch device, respectively control the rotation of the tape reels 2 and the linkage between the tape reels 2 and the clutches are realized.

[0040] Specifically, the output end of the motor 1 is composed of a gear-shaped rotating shaft 11 and a cylindrical rotating shaft 12 alternately, that is, a plurality of gear-shaped rotating shafts 11 are separated by a cylindrical rotating shaft 12, and the gear-shaped rotating shaft 11 drives the gear 3 to move, and the cylindrical rotating shaft The shape rotating shaft 12 is mainly used to separate a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com