Prestressed concrete prefabricated part manufacturing and forming method

A technology for concrete prefabricated parts and a forming method, which is applied in the directions of forming indenters, manufacturing tools, unloading devices, etc., can solve the problem of increasing the difficulty of making prestressed concrete prefabricated parts, low efficiency of prestressed concrete prefabricated parts, and complicated mold installation and disassembly. Complex problems, to achieve the effect of simple and convenient installation and disassembly methods, improve production efficiency, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings. In the process, in order to ensure the clarity and convenience of illustration, we may exaggerate the width of the lines or the size of the constituent elements in the diagram.

[0038] In addition, the following terms are defined based on the functions in the present invention, and may be different according to the user's or operator's intention or practice. Therefore, these terms are defined based on the entire content of this specification.

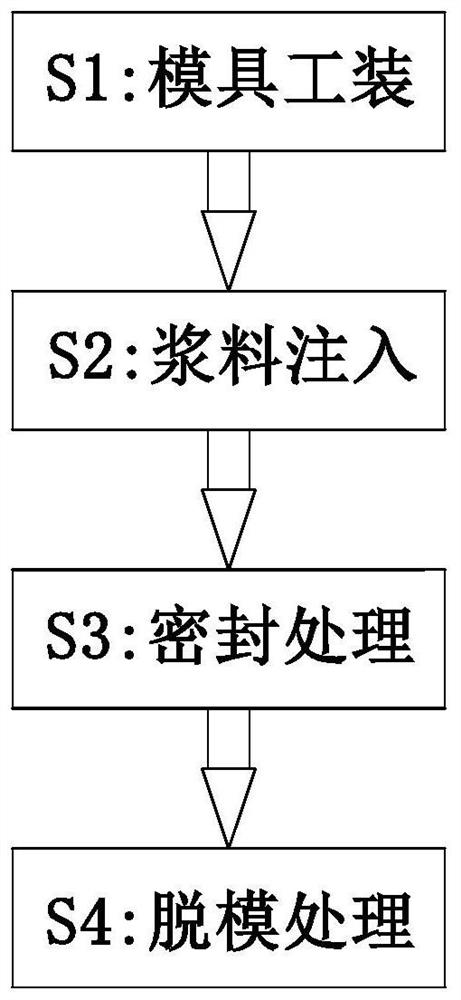

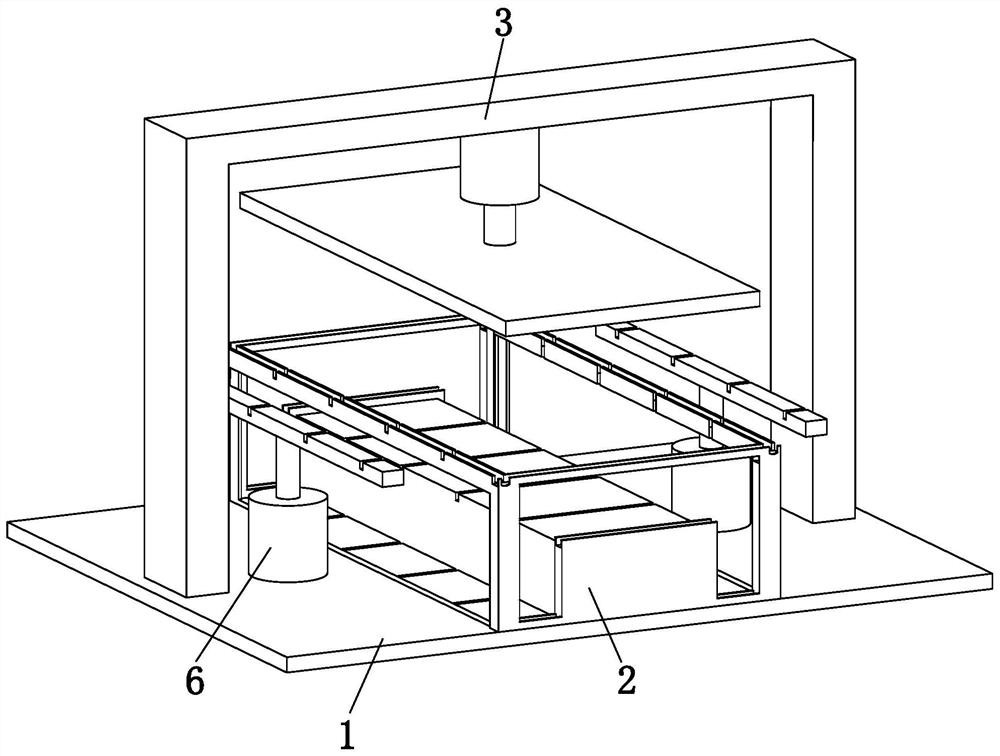

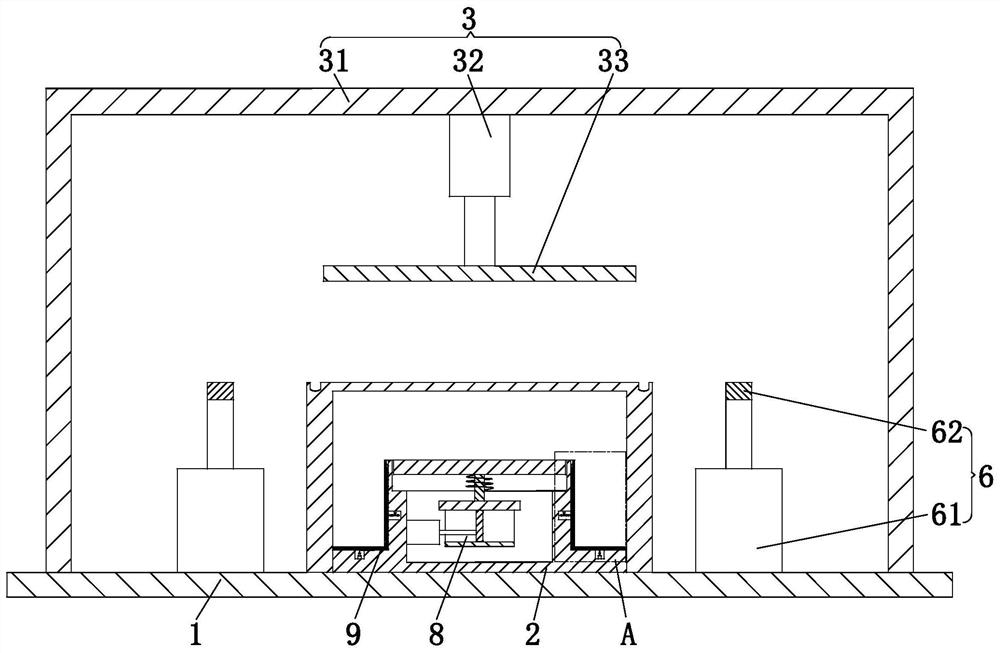

[0039] Such as Figure 1 to Figure 11As shown, a prestressed concrete prefabricated production molding method, which uses a prestressed concrete prefabricated production molding equipment, the prestressed concrete prefabricated production molding equipment includes a bottom plate 1, a mold frame 2, an upper sealing mechanism 3, Side plate 4, sliding mechanism 5, jacking mechanism 6, partition plate 7, lifting mechanism 8 and bottom dem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com