High-safety power line repair tower lifting device

A lifting device and safety technology, which is applied in the field of electric power emergency repair tower lifting device, can solve the problems of poor flexibility, large limitations of electric power repair work, unfavorable good adjustment, etc., and achieve the effect of convenient and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

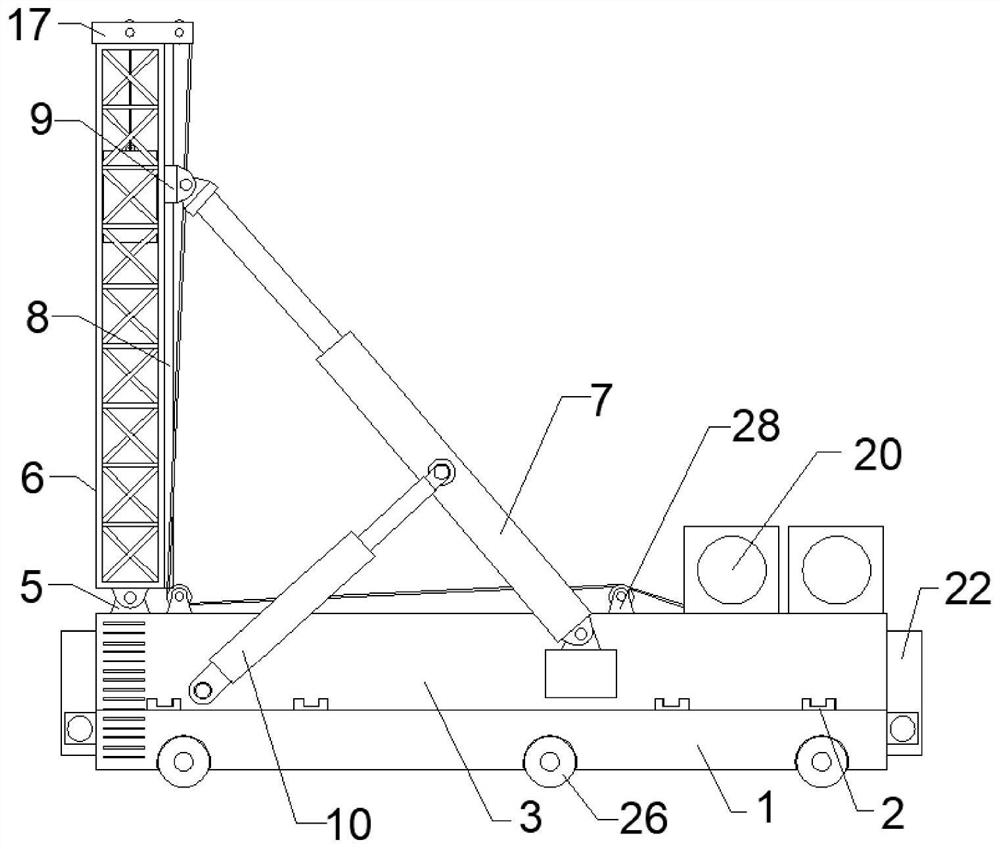

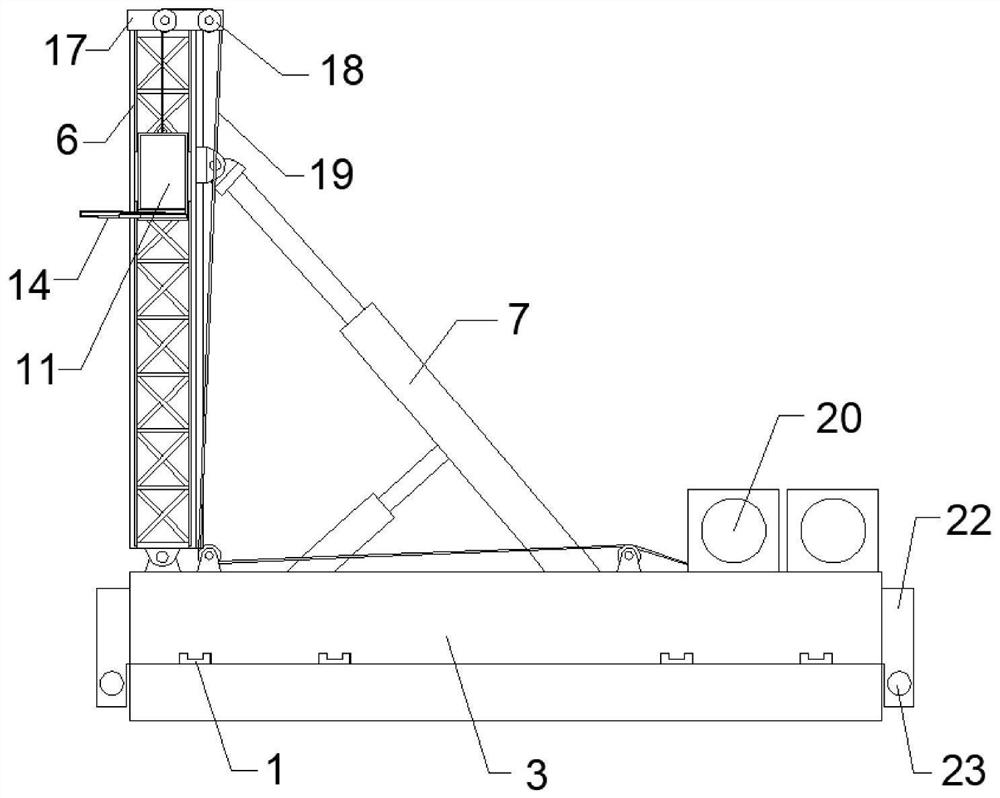

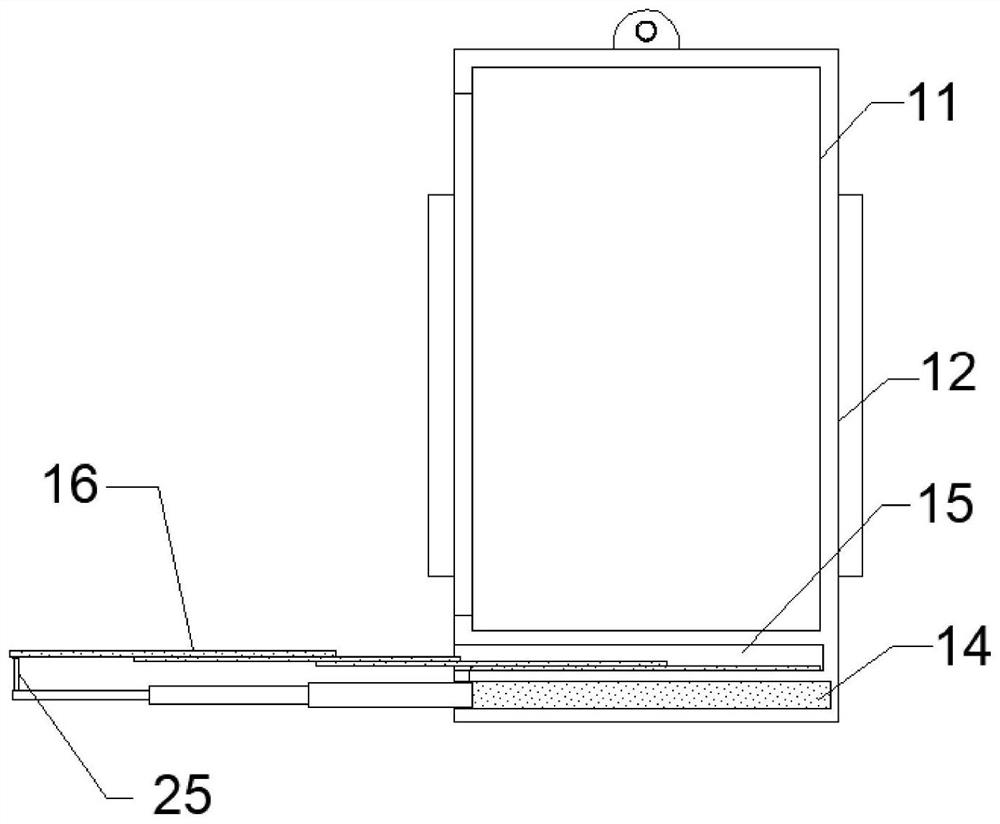

[0026] Such as Figure 1-6 As shown, a high-safety electric emergency repair tower lifting device includes a base 1, a moving base 3, a lifting tower 6, a threaded rod 21, a multi-stage hydraulic rod 14 and a slide plate 16, and guide rails are welded on the top of the base 1 2. The top of the guide rail 2 is slidably connected with a moving seat 3, and one end of the top of the moving seat 3 is rotated through a bearing seat 5 to install a lifting tower 6, and a car 11 is arranged inside the lifting tower 6, and the inside of the car 11 A plate groove 15 is opened at the bottom, and slide plates 16 are stacked and arranged in the plate groove 15. A multi-stage hydraulic rod 14 is fixedly installed in the car 11 and at the bottom of the plate groove 15, and the multi-stage hydraulic rod 14 outputs The end top is welded and connected with the end of the slide plate 16 at the top of the plate groove 15 through the support column 25, and the first slide rail 8 is welded on one si...

Embodiment 2

[0040] Such as Figure 1-6 As shown, a high-safety electric emergency repair tower lifting device includes a base 1, a moving base 3, a lifting tower 6, a threaded rod 21, a multi-stage hydraulic rod 14 and a slide plate 16, and guide rails are welded on the top of the base 1 2. The top of the guide rail 2 is slidably connected with a moving seat 3, and one end of the top of the moving seat 3 is rotated through a bearing seat 5 to install a lifting tower 6, and a car 11 is arranged inside the lifting tower 6, and the inside of the car 11 A plate groove 15 is opened at the bottom, and slide plates 16 are stacked and arranged in the plate groove 15. A multi-stage hydraulic rod 14 is fixedly installed in the car 11 and at the bottom of the plate groove 15, and the multi-stage hydraulic rod 14 outputs The end top is welded and connected with the end of the slide plate 16 at the top of the plate groove 15 through the support column 25, and the first slide rail 8 is welded on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com