Automatic control system for silicothermic process semicontinuous magnesium smelting furnace burden calcination

An automatic control system, semi-continuous technology, applied in the field of automatic control system for calcination of furnace materials for thermal magnesium smelting, can solve the problems of controlling temperature output value, inability to calculate deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

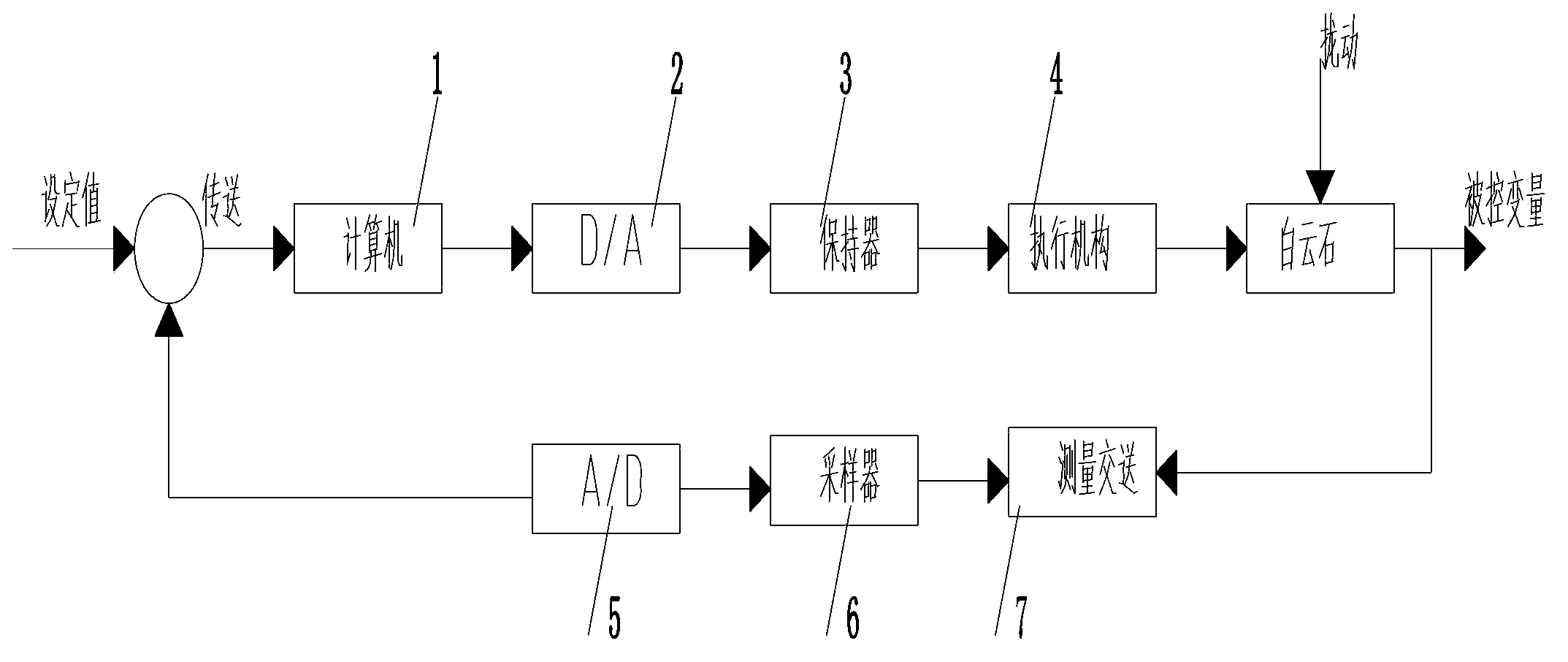

[0009] Embodiment 1: Using the working principle of the closed-loop control system :

[0010] When there is a deviation in the calcination process for some reason, the controllers such as computer 1, converter 2, and holder 3 will calculate the deviation according to the set control temperature, and then output a control value △u to the actuator 4 to reduce the deviation , until the control requirements are met, at this time the controller output u will remain at a certain value and will not change.

Embodiment 2

[0011] Embodiment 2 adopts the purpose of automatic control:

[0012] The purpose of automatic control is to keep the system stable when the temperature setting value of each section of the rotary kiln changes or is disturbed by the outside world. A well-controlled system should be stable, rapid and accurate after the system is disturbed. To approach and return to the set value, evaluate the quality indicators of the system, and have the characteristic parameters of the step response curve (attenuation ratio overshoot, recovery time, residual error) and deviation integral performance indicators, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com