Oil-water separator for kitchen waste

An oil-water separator, kitchen waste technology, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of unsatisfactory separation effect and low efficiency, and achieve the effect of oil-water separation, fast and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The oil-water separator for kitchen waste according to the present invention will be further described in detail through specific examples below.

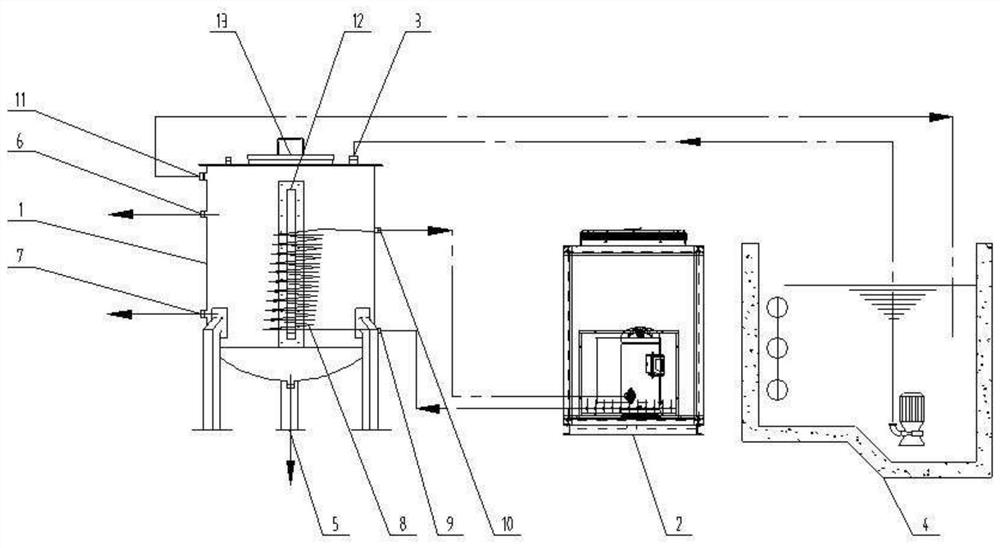

[0012] Such as figure 1 As shown, a kind of oil-water separator used for kitchen waste comprises a separation tank 1 and a constant temperature water heater 2, the top of the separation tank 1 is provided with a feeding port 3, and the feeding port 3 and the kitchen waste sewage pool 4 The bottom of the separation barrel 1 is provided with a sewage outlet 5, the side of the separation barrel 1 is respectively provided with an oil outlet 6 and a water outlet 7 from top to bottom, and the inside of the separation barrel 1 is provided with a coil 8, a coil 8 The two ends connected to the side of the separation barrel 1 are the circulating water inlet 9 and the circulating water outlet 10 respectively, and the circulating water inlet 9 and the circulating water outlet 10 are connected with the constant temperature water heater 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap