Nylon cord elastic V belt, engine front end wheel train and test method

A nylon thread and elastic technology, applied in the field of engine accessories assembly, can solve problems such as belt tension not meeting operating requirements, lack of self-maintenance, belt drive failure, etc., to avoid manual maintenance, save assembly space and cost, and reduce belt tension Attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0026] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

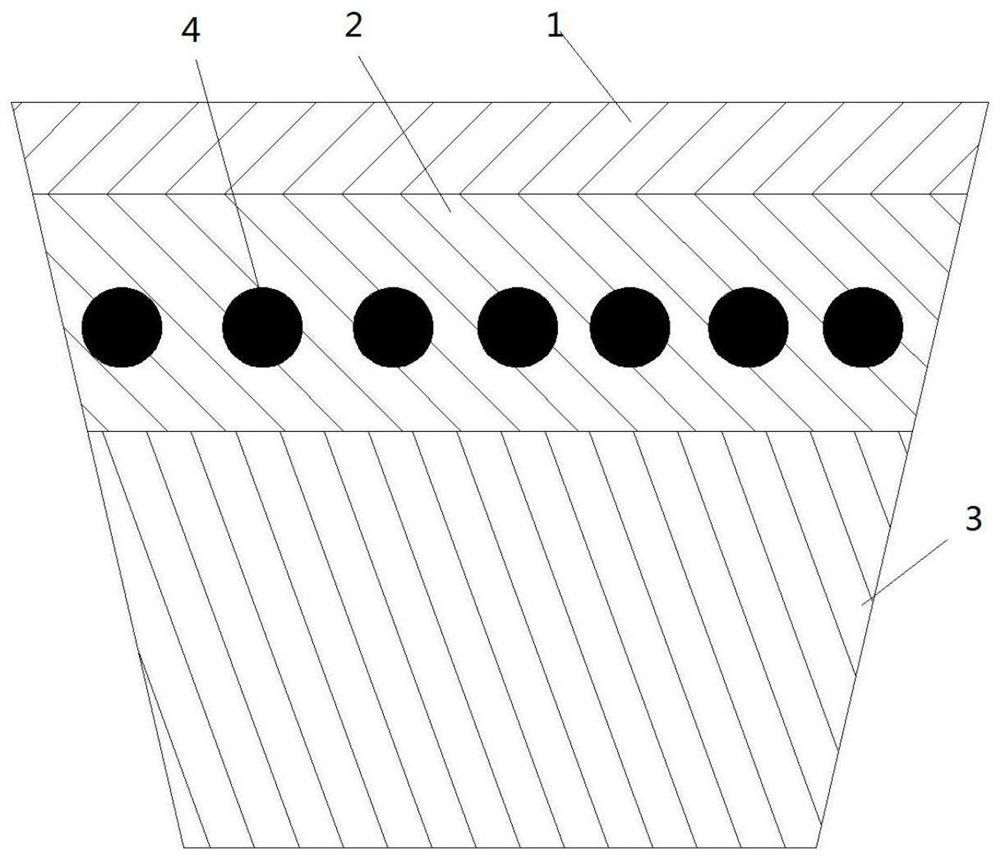

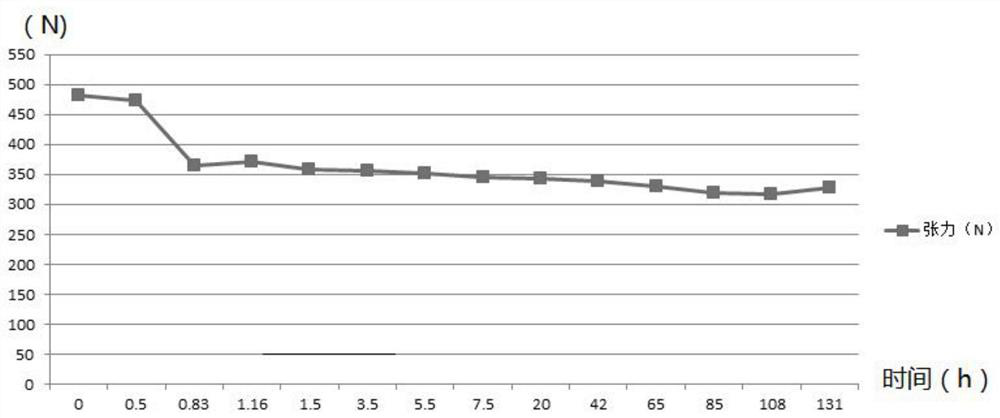

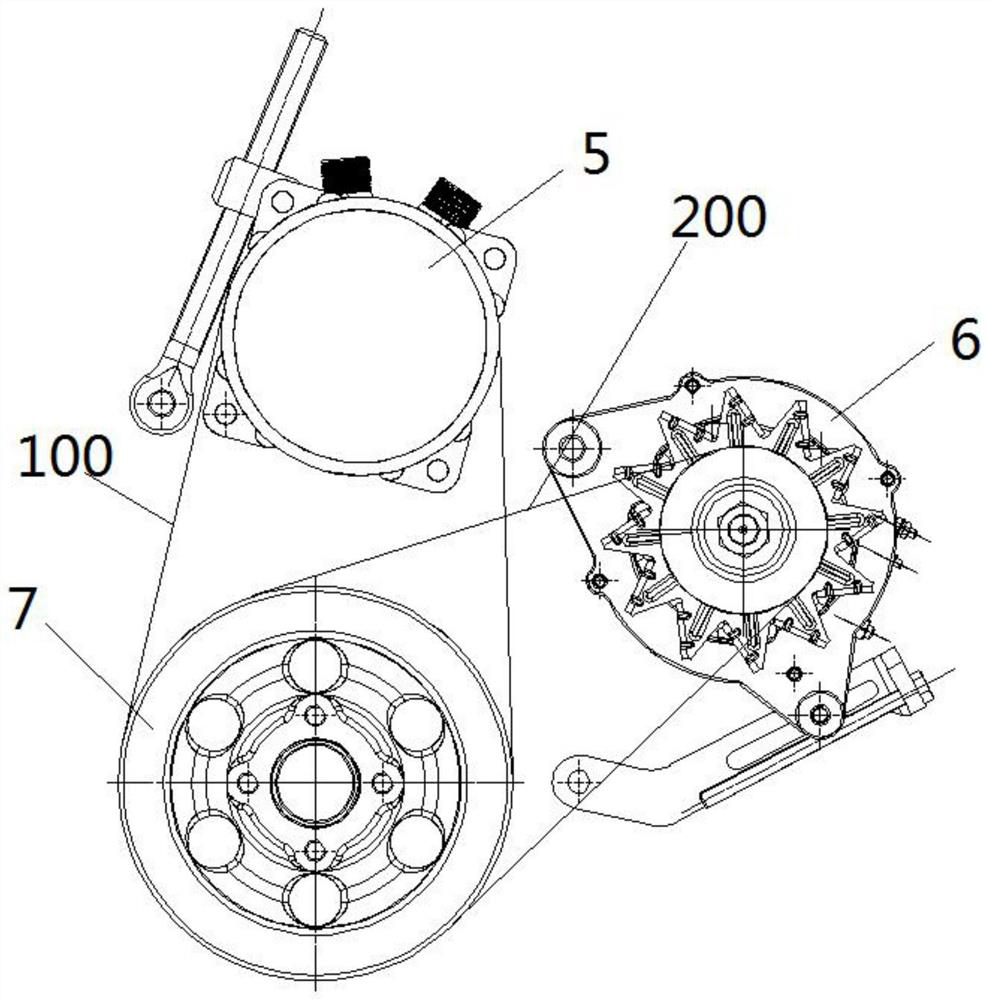

[0027] like figure 1 A nylon rope elastic V-belt shown includes a V-belt body, and the V-belt body is a canvas outer layer 1, a buffer rubber layer 2, and a main rubber layer 3 from the outside to the inside, and the buffer rubber layer 2 is arranged on the canvas. Between the outer layer 1 and the main body rubber layer 3, and the buffer rubber layer 2 is provided with polyester cords along its length. The improvement point of the present application is to replace the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com