Double-wool flexible shaft and machining method thereof

A processing method and flexible shaft technology, which are applied to double wool flexible shafts and their processing, flexible shafts and their corresponding processing fields, can solve problems such as loose wires, and achieve extended service life, reasonable design, and simple and intuitive overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a double-pile flexible shaft and a processing method thereof, and the specific scheme is as follows.

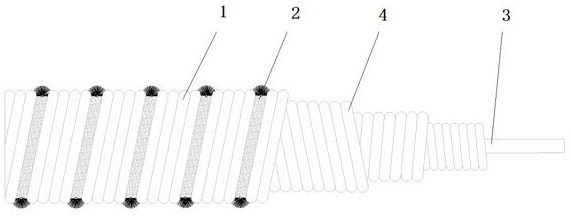

[0028] Such as figure 1 As shown, a double-pile flexible shaft is suitable for some environments that are very sensitive to friction and noise, such as electric seats of luxury cars, etc., and is formed by winding the shaft core and the outer layer of the flexible shaft, and the outer layer of the flexible shaft It includes a plurality of outer layer steel wires 1 and two woolen yarns 2, the plurality of outer layer steel wires 1 and the two woolen yarns 2 are arranged side by side and spirally wound together on the outer peripheral side of the shaft core.

[0029] The shaft core is formed by winding a central steel wire 3 and the inner layer of a multi-layer flexible shaft. The coils are stacked in sequence, spirally wound on the outer peripheral side of the central steel wire 3 , and the winding directions of the inner layers of the flexible s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com