Weighing equipment for commercial concrete production

A technology for commercial concrete and equipment, applied in the field of weighing equipment for commercial concrete production, can solve problems such as poor equipment use effect, equipment failure, and equipment failure, and achieve the effect of improving the actual use effect and preventing the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

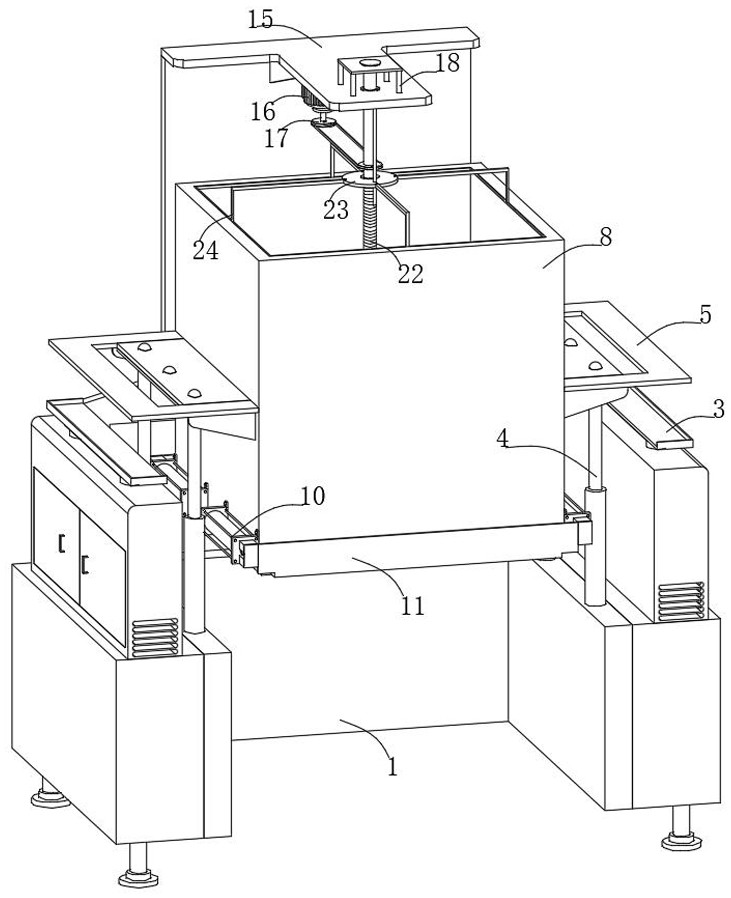

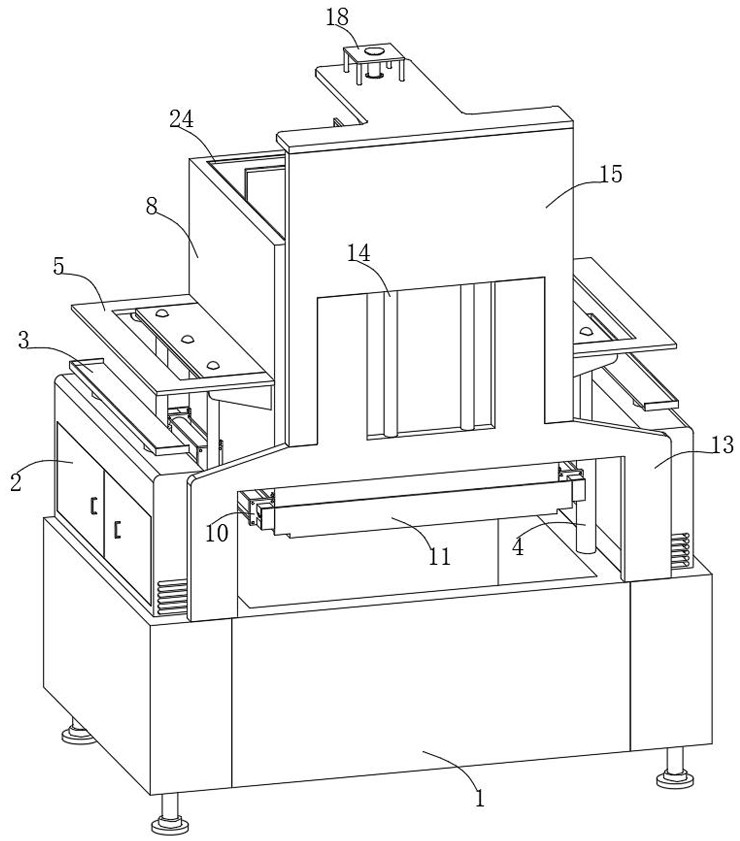

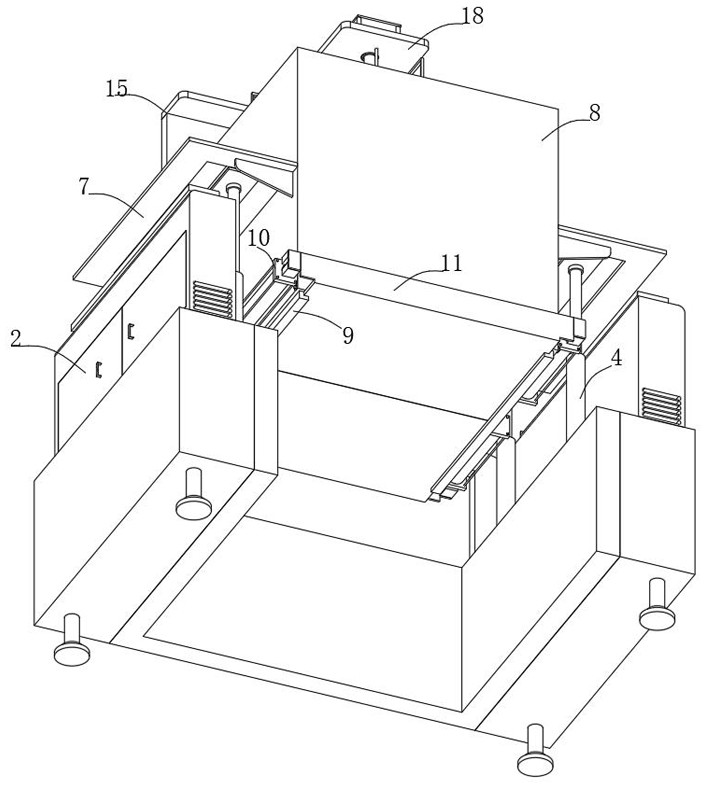

[0029] Embodiment one, with reference to Figure 1-10: A kind of weighing equipment for commercial concrete production, including weighing mechanism 27, weighing mechanism 27 includes base 1, the establishment of base 1 provides the installation basis for other functional components of the equipment, and simultaneously enables the equipment to be placed firmly on the designated place of use , the top of the base 1 is fixedly connected with a scale body 2 close to the edges of both sides. The establishment of the scale body 2 enables the equipment to effectively weigh the concrete quality. The input end of each scale body 2 is fixedly connected with a tray 3, and the tray 3 The establishment of the storage frame 8 can be stably placed on the top of the scale body 2 through the connecting plate 7, and a group of first oil cylinders 4 are fixedly connected to both sides of the top center of the base 1. The establishment of the first oil cylinder 4 can effectively carry out the sto...

Embodiment 2

[0030] Embodiment two, refer to Figure 4-10 : the top of each connecting plate 7 is equidistantly provided with a plurality of limit holes along the horizontal direction, the setting of the limit holes cooperates with the limit block 6 to enable the support plate 5 and the connection plate 7 to be connected firmly, and the top of each support plate 5 is located at multiple The inside of each limit hole is fixedly connected with the limit block 6, and the outer surface on both sides of each sealing plate 11 and the inner surface wall on one side of the two L-shaped sliders 9 are respectively attached, and the bottom of each sealing plate 11 and the two L-shaped The inner bottom surface of the slide bar 9 is all attached, and each scraper bar 12 is a triangular columnar structure, and the outer surfaces on both sides of each scraper bar 12 and the inner surface walls on both sides of the storage frame 8 are respectively attached, and the bottom of each connecting plate 7 The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com