Waterproof hollow plate

A hollow and cavity technology, which is applied in the liquid tightness measurement using liquid/vacuum degree, by detecting the appearance of fluid at the leakage point, testing the hardness of materials, etc., can solve the troublesome detection, inconvenient use, and affect the production of hollow boards, etc. problems, to achieve the effect of good waterproof performance, easy to use, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

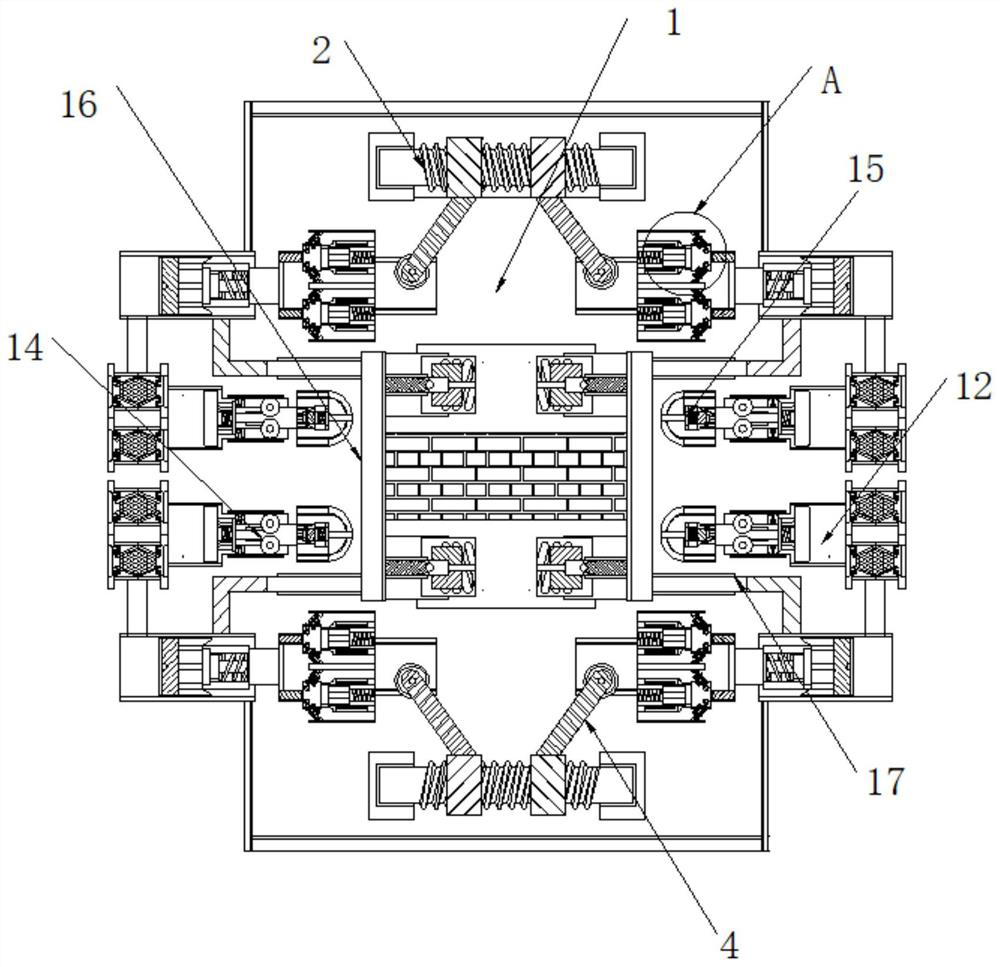

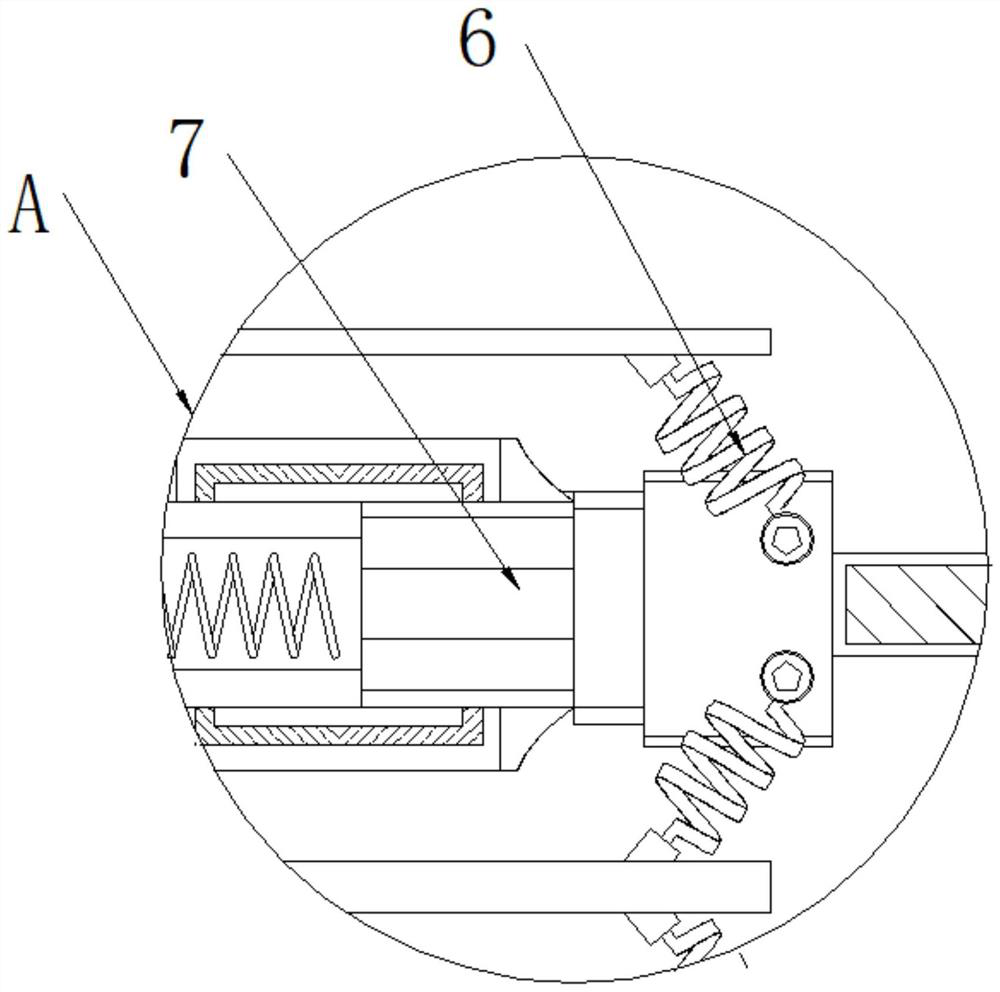

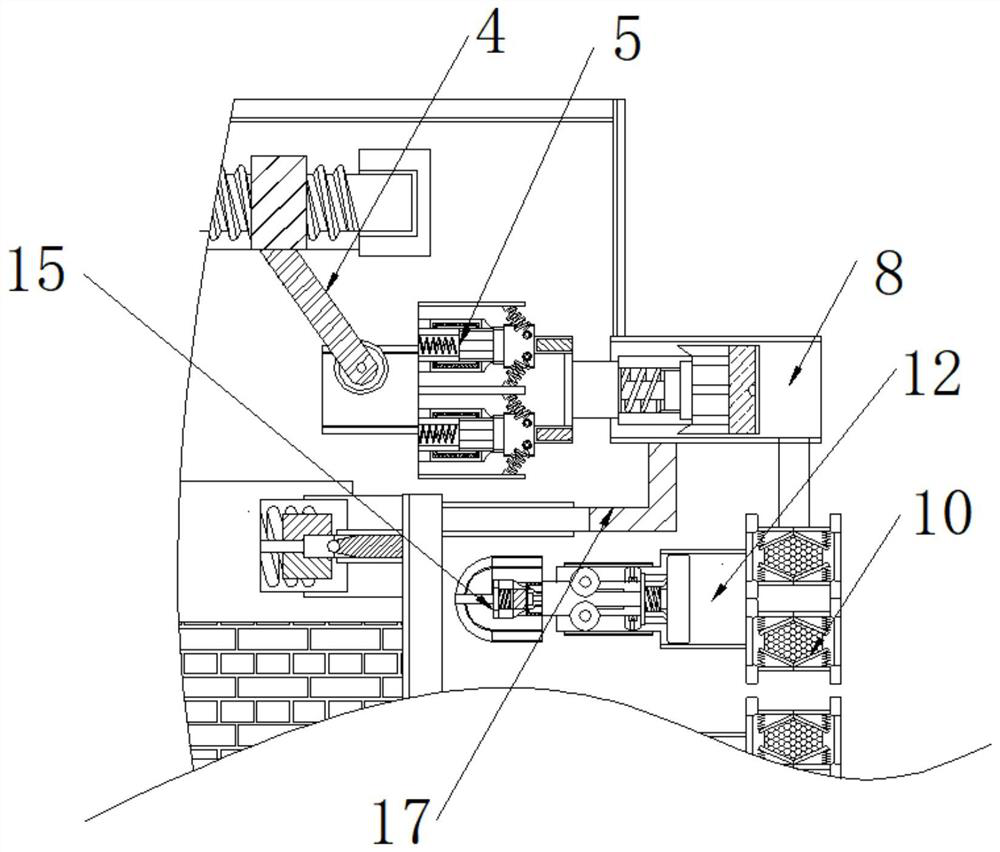

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] as attached figure 1 to attach Figure 8 Shown:

[0025] The invention provides a waterproof hollow board, which includes a detection frame 1, a threaded post 2 is connected to the interior of the detection frame 1 for rotation, a moving sleeve 3 is slidably connected to the outer surface of the threaded post 2, and a push rod is movably connected to the side surface of the moving sleeve 3 4. The inside of the detection frame 1 is provided with a sliding groove compatible with the threaded column 2, the diameter of the moving sleeve 3 is larger than the diameter of the threaded column 2, and the other end of the push rod 4 is movably connected to the elastic frame 5, and the inside of the elastic frame 5 A scroll spring 6 is movably connected, and a push post 7 is movably connected to the side surface of the elastic frame 5, and one end of the push post 7 runs thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com