Portable equipment interface testing device and method

A portable equipment and interface testing technology, applied in the electrical field, can solve the problems of wasting manpower and time, low test efficiency, dense pinholes, etc., and achieve the effect of convenient testing, small influence of temperature and humidity on measuring equipment, and low dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

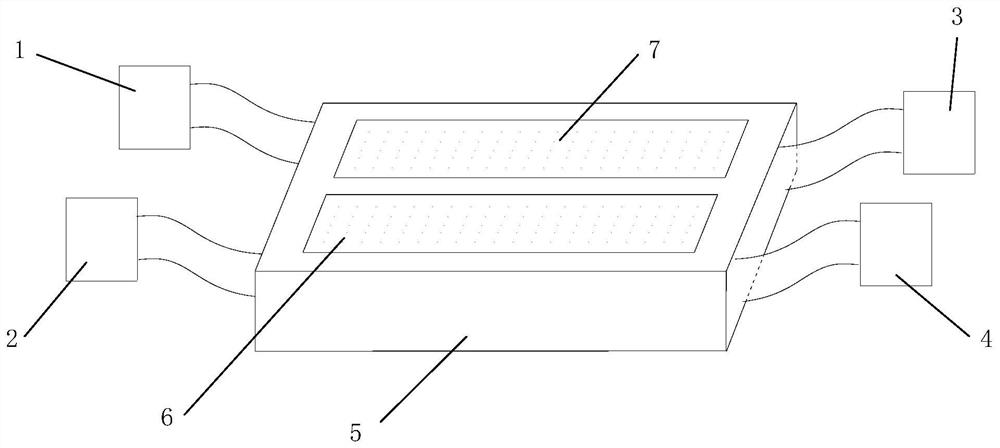

[0028] An embodiment of the present invention provides a portable device interface testing device, the device includes a platform test box, a plurality of adjustable joints, the plurality of adjustable joints are respectively connected to the left and right sides of the platform test box; on the test box A plurality of test areas are arranged on the surface, each test area corresponds to an adjustable joint, and the test area is correspondingly connected to the adjustable joint.

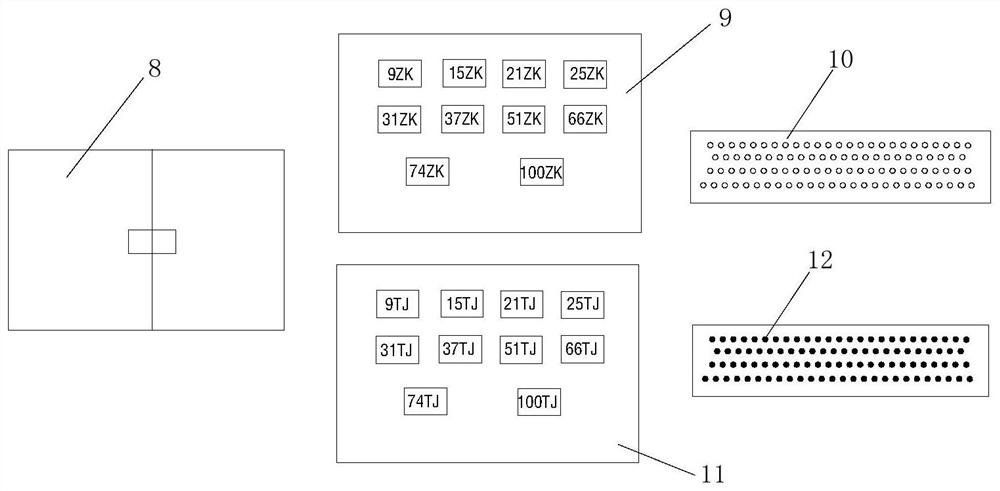

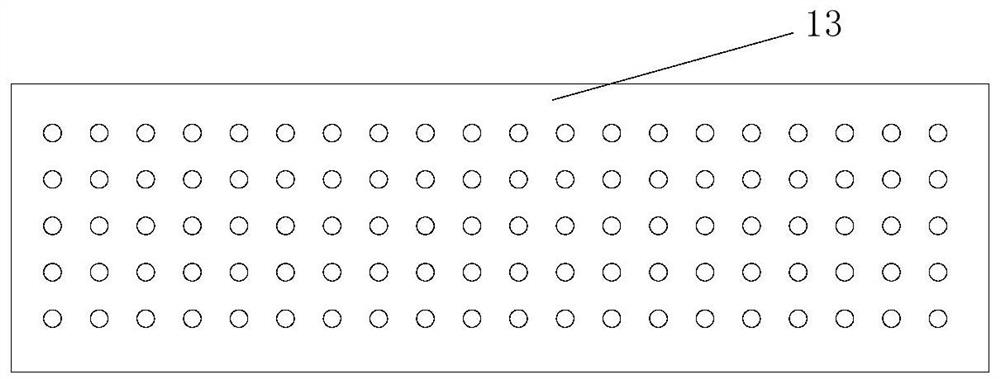

[0029] (1) Multiple test holes are provided on each test area, and each test hole corresponds to the pins on the adjustable connector one by one.

[0030] (2) The inside of the adjustable connector includes two modes: a jack specification selection area and a pin selection area;

[0031] The jack specification selection area is provided with a jack specification key selection area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com