A micro force measuring device

A measuring device, a technology of tiny force, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, measurement of balance force using force, etc. Difficulty in calibration, measurement data acquisition errors and other problems, to achieve the effect of small impact on measurement results, reasonable and reliable solutions, and small impact of measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

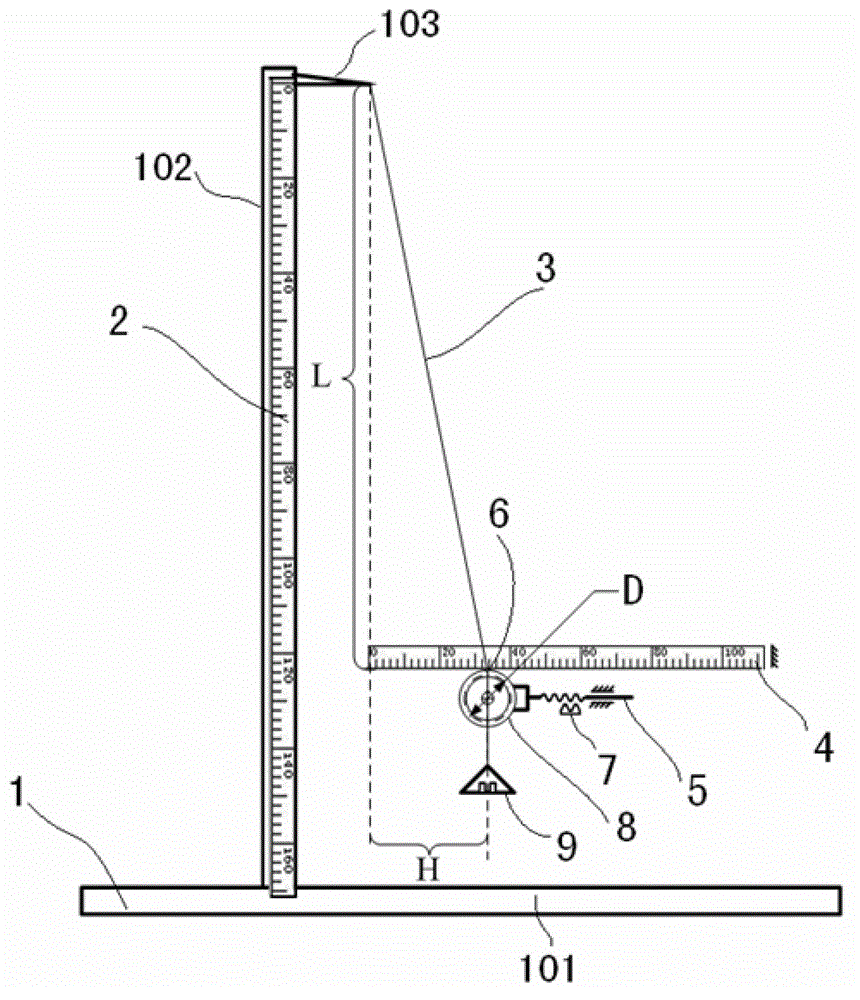

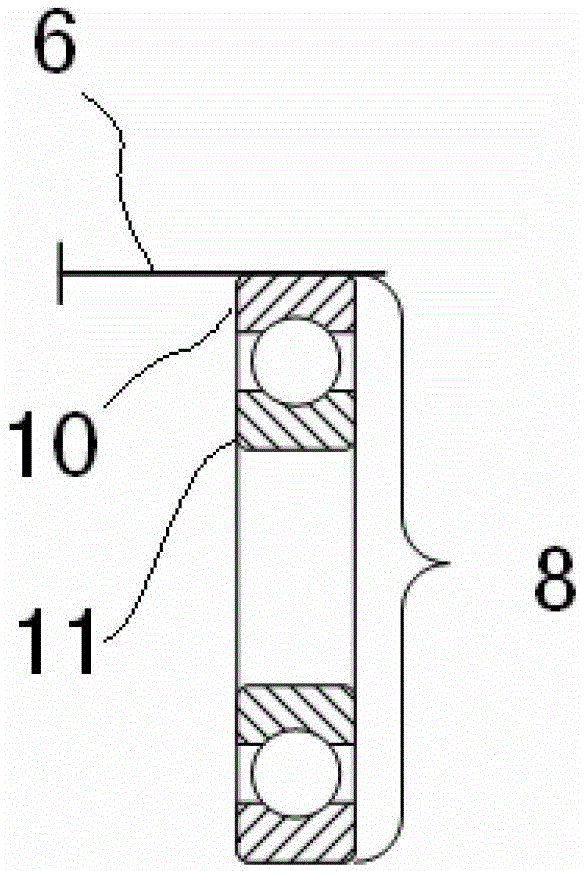

[0024] This embodiment is an example of using the present invention to measure the starting torque of a bearing. The object 8 to be tested is a bearing, the fixed part 11 is the inner ring of the bearing, the movable part 10 is the outer ring of the bearing, one end of the horizontal bracket 5 fixes the inner ring of the bearing, and the other end moves the horizontal bracket 5 along the horizontal direction through the positioning mechanism 7 To move, the movable part 10 of the measured object 8 is fixed with a toggle mechanism 6, and the toggle mechanism 6 is a thin steel needle. In this embodiment, the position adjustment mechanism 7 is a screw nut mechanism.

[0025] In the initial state, the silk thread 3 and the weight 9 hang freely, and the horizontal bracket 5 is moved to make the toggle mechanism 6 fixed on the outer ring of the bearing contact with the silk thread 3, and the cantilever 103 of the workbench 1 is read to the toggle mechanism through the vertical scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com