Method for measuring stress intensity factors of multi-round-hole multi-crack anisotropic material

A technology of stress intensity factor and anisotropy, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve problems such as difficulty in obtaining high-precision solutions, dependence, and failure to consider the surface stress of round holes and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preferred embodiment 1, the specific steps of the method for measuring the stress intensity factor of the multi-hole multi-crack anisotropic material disclosed in this embodiment are as follows.

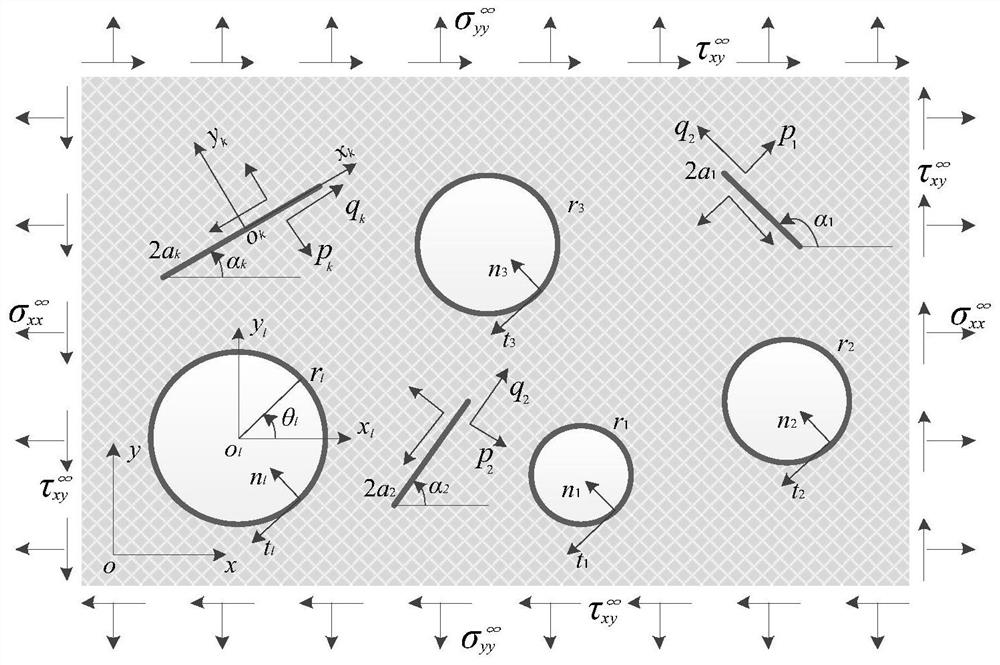

[0054] The first step is to construct an anisotropic body, such as figure 1 As shown, the anisotropic body contains L circular holes (radius r l ,l=1,2,3,…,L) and K cracks (half-length a k , inclination α k ,k=1,2,3,…,K), the far-field effect has uniform stress ( and ), the hole and the surface of the crack act on the surface of arbitrarily distributed normal stress and shear stress (n k , t k and p l ,q l ).

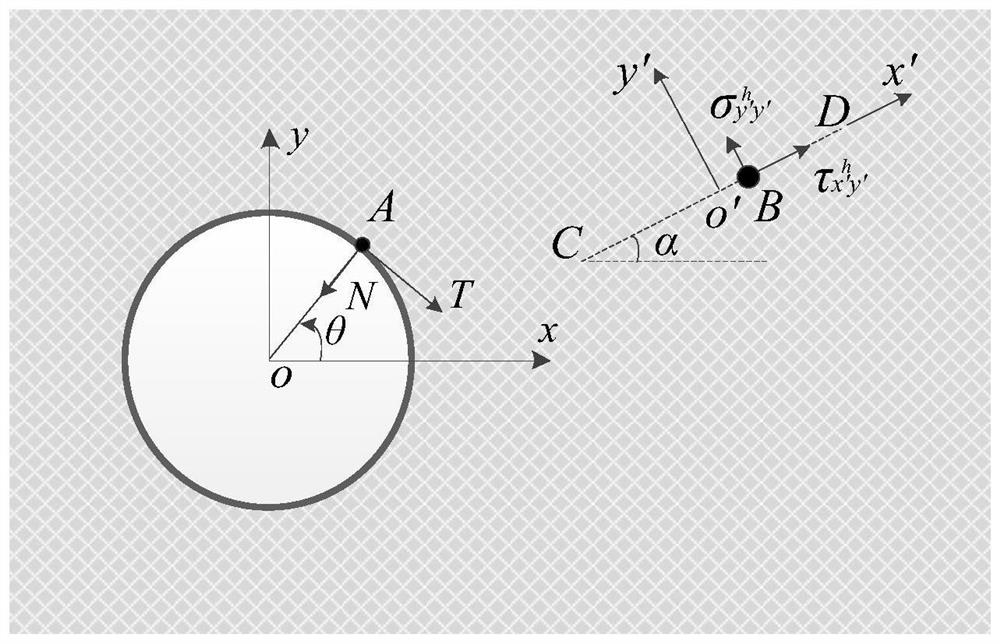

[0055] The second step is to construct a planar unit model with a single circular hole, such as figure 2 As shown, when the plane unit model contains a single circular hole (aperture r) and any point A(r, θ) of the anisotropic body acts on the concentrated force (N, T), any point B on the virtual crack CD (inclination angle α) normal and tangential stress ...

Embodiment 2

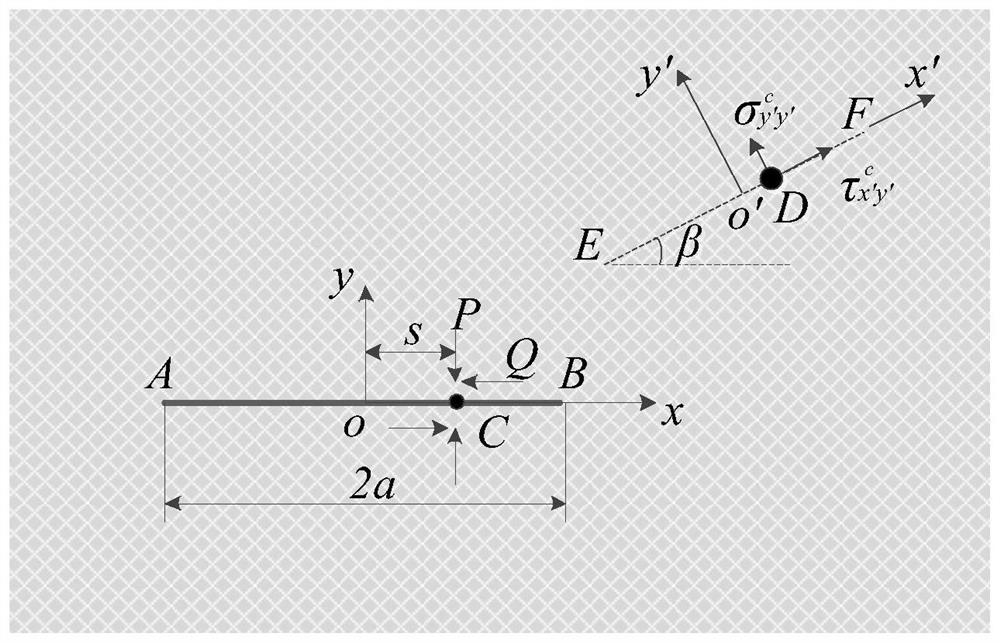

[0104] Preferred Embodiment 2. This embodiment is used to calculate isotropic materials. Such as Figure 4 As shown, construct an infinite isotropic flat plate (Poisson's ratio ν=0.3) containing a horizontal crack with a radius r and a length 2a (a=0.5r), and a uniform Brass stress σ acts on the vertical crack surface at infinity, s and t denote the horizontal and vertical distances between the center of the circle and the midpoint of the crack, respectively.

[0105] Let the two roots u of the characteristic equation of the anisotropic material j (j = 1, 2) are approximately equal, and the basic stress solution of the isotropic body with a single circular hole subjected to the concentrated force on the orifice surface is obtained approximately, and the crack inclination angle α in the basic solution is set to 0, and the stress caused by the concentrated force on the surface of the circular hole is obtained The normal and tangential stresses on the horizontal crack surface. ...

Embodiment 3

[0135] Preferred Embodiment 3. This embodiment can be used to calculate anisotropic materials. Such as Figure 5 As shown, construct an infinite anisotropic flat plate with a radius r and a length 2a (a=0.5r) inclined crack (inclination angle α=30°), and biaxial tensile stress acts at infinity Uniformly distributed surface stress n(n=-cos 2 θMPa), s represents the distance between the center of the circle and the midpoint of the crack. Anisotropic material properties are:

[0136]

[0137] S1: Make the crack inclination angle α=30 ° in the basic solution, obtain the surface normal direction and tangential stress of the inclined crack surface caused by the concentrated force on the surface of the circular hole;

[0138] S2: Determine the normal and tangential stresses on the surface of the circular hole caused by the concentrated force on the surface of the crack;

[0139] S3: Based on the derived basic solution and the stress boundary conditions of the circular hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com