Simplified rotating module

A technology of rotating modules and rotating shafts, which is applied to TVs, color TV parts, electrical components, etc. It can solve the problems of large volume of kits, electrical signal introduction, and multiple parts of multiple kits, so as to reduce complexity and difficulty. , Miniaturized structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

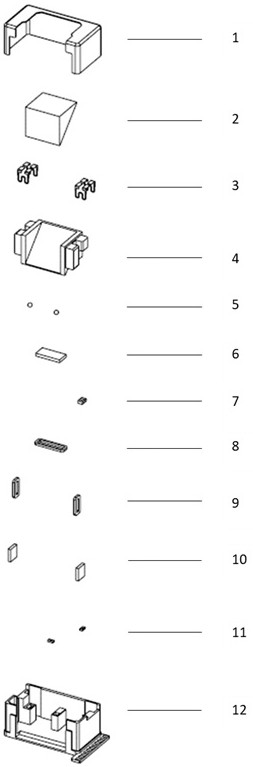

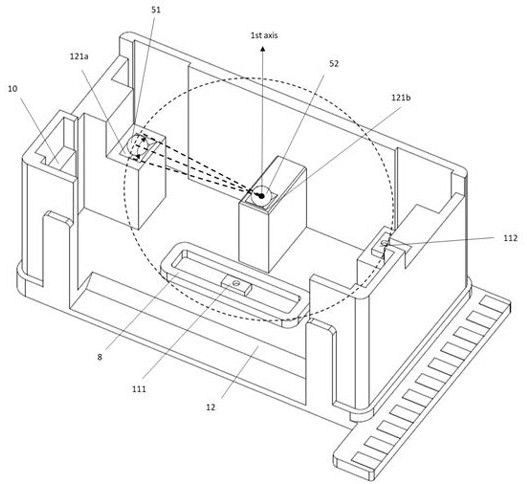

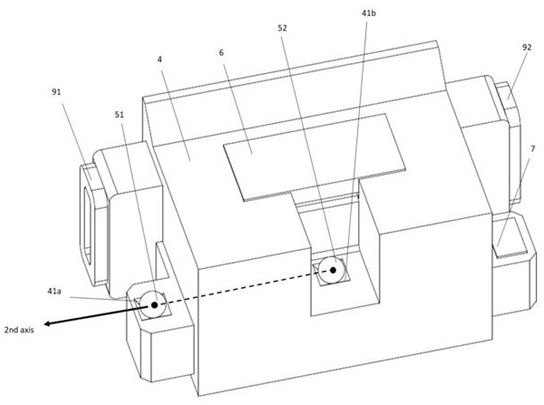

[0035] Such as figure 1 As shown, the simplified rotary module includes: a housing 1; a bearing seat 4 for carrying the optical path adjustment assembly 2 for adjusting the angle of the optical path. In this embodiment, the optical path adjustment assembly 2 is a prism, and the upper surface of the bearing seat 4 is provided with There are grooves corresponding to the prism; a base 12 forms an accommodating space with the housing 1 for containing and supporting the bearing seat 4, and has a rotation avoidance space for the bearing seat 4; a supporting component 5 is arranged between the bearing seat 4 and the base 12. Satisfy and limit the rotation of the bearing seat 4 around the first rotation axis and the second rotation axis respectively, and the first rotation axis and the second rotation axis are perpendicular to each other; a clamping assembly 3 is arranged between the bearing base 4 and the base 12 , providing a clamping force to keep the bearing seat 4, the base 12 an...

Embodiment 2

[0049] Such as Figure 7 , Figure 8 As shown, the difference between this simplified rotary module and Embodiment 1 is that two arc-shaped tracks 1211a, 1211b corresponding to the balls 51, 52 are arranged on the base 12, and the virtual centers of the two arc-shaped tracks 1211a, 1211b overlap, and the bearing seat 4 Accommodating point grooves 43a, 43b corresponding to the two balls 51, 52 are provided on the top. In this embodiment, the first rotation axis is perpendicular to the plane where the two arc-shaped tracks 1211a, 1211b are located and passes through the virtual center of the arc-shaped tracks 1211a, 1211b, and the second rotation axis is the center of the two balls 51, 52. virtual connection. When the electromagnetic rotational driving force acts on the bearing seat 4, the balls 51, 52 move clockwise or counterclockwise along the corresponding arc-shaped tracks 1211a, 1211b, and the bearing seat 4 rotates with the first rotation axis passing through the virtua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com