Intelligent screening equipment for garbage classification

A screening equipment and garbage sorting technology, which is applied in the direction of filtering, solid separation, grille, etc., can solve the problems of manpower consumption, slow efficiency, and statistical classification errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

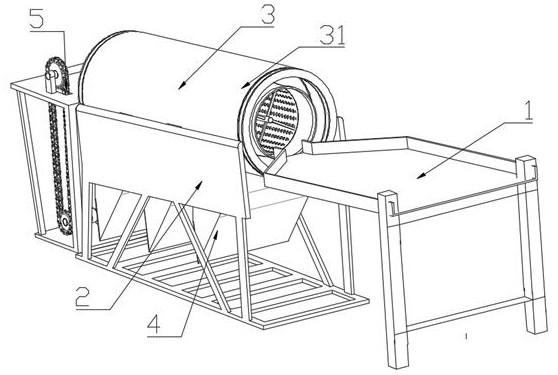

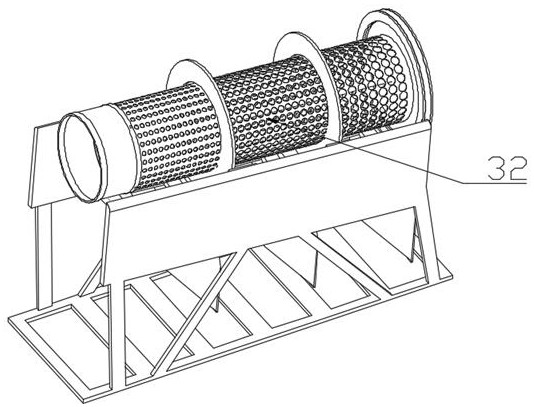

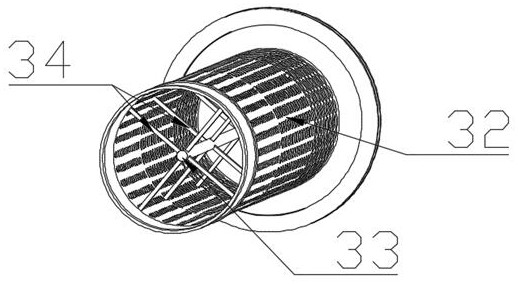

[0025] Such as Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention: an intelligent screening device for garbage classification, including a material receiving assembly 1, a screening base 2, a screening mechanism 3, a discharging mechanism 4 and a driving mechanism 5, and the screening base 2 is set on On the ground, the screening mechanism 3 is arranged on the top of the screening base 2, the discharge mechanism 4 is arranged in the inner cavity of the screening base 2, and the top of the discharge mechanism 4 is connected with the screening mechanism 3 The bottom of the material receiving assembly 1 is arranged obliquely at the feed end of the screening mechanism 3, and the discharge end of the material receiving assembly 1 extends to the feed end of the screening mechanism 3, the The driving mechanism 5 is arranged at the tail end of the screening base 2, and the working end of the driving mechanism 5 is fixed at the center position of the tail of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com