Hosiery machine metering system for field yield statistics of operators

A metering system and hosiery machine technology, which is applied to the parts, packaging, and packaging protection of strapping machinery, can solve the problems of difficult production management, statistical double counting, and error-prone, and achieve the effect of avoiding statistical confusion and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

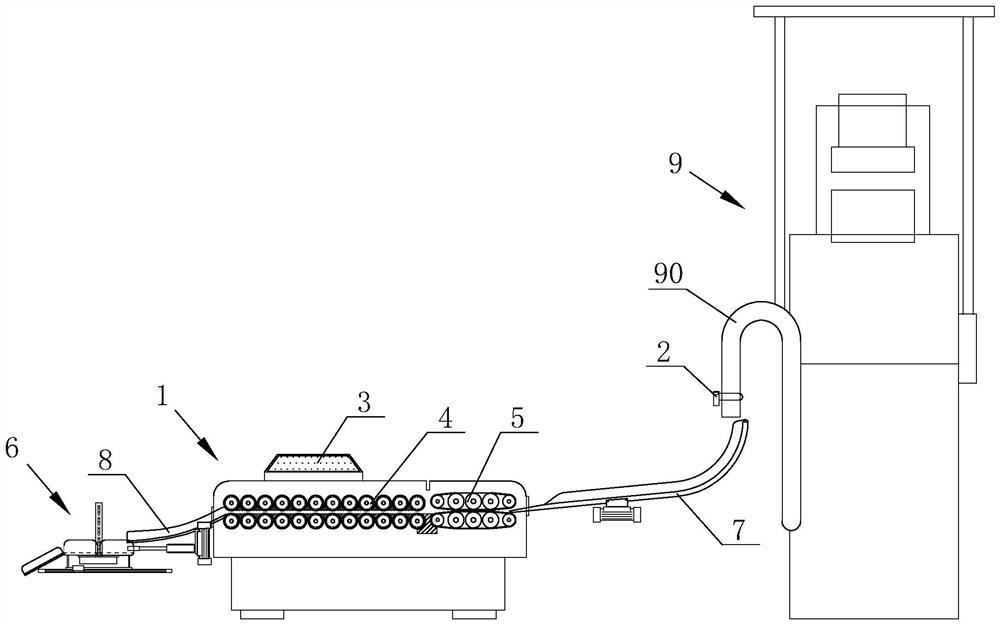

[0033] Such as Figure 1 to Figure 14 The hosiery machine metering system shown for on-site production statistics by operators includes a main body 1, a counting device, an intelligent controller, a display device, a sock body 10 sorting device, and a batch packing device 6, and the intelligent controller is integrated on the main body In 1, the display device adopts a touch display 3, which is arranged on the top of the main body 1. The touch display 3 is used to display the model, size, current output, production progress and raw material balance of the socks produced by the corresponding hosiery machine 9.

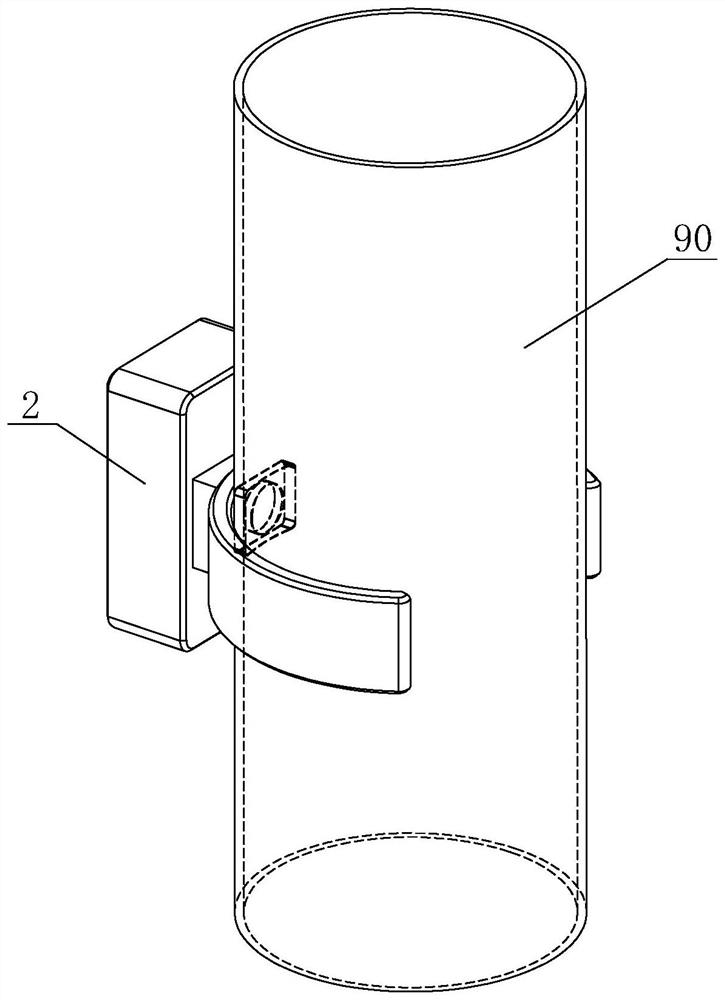

[0034] The counting device adopts an infrared light sensor 2, which is set independently from the main body 1, and the infrared light sensor 2 is detachably installed on the transparent sock outlet side wall of the hosiery machine 9, and the sensing probe of the infrared light sensor 2 faces the outlet. The cavity of the sock.

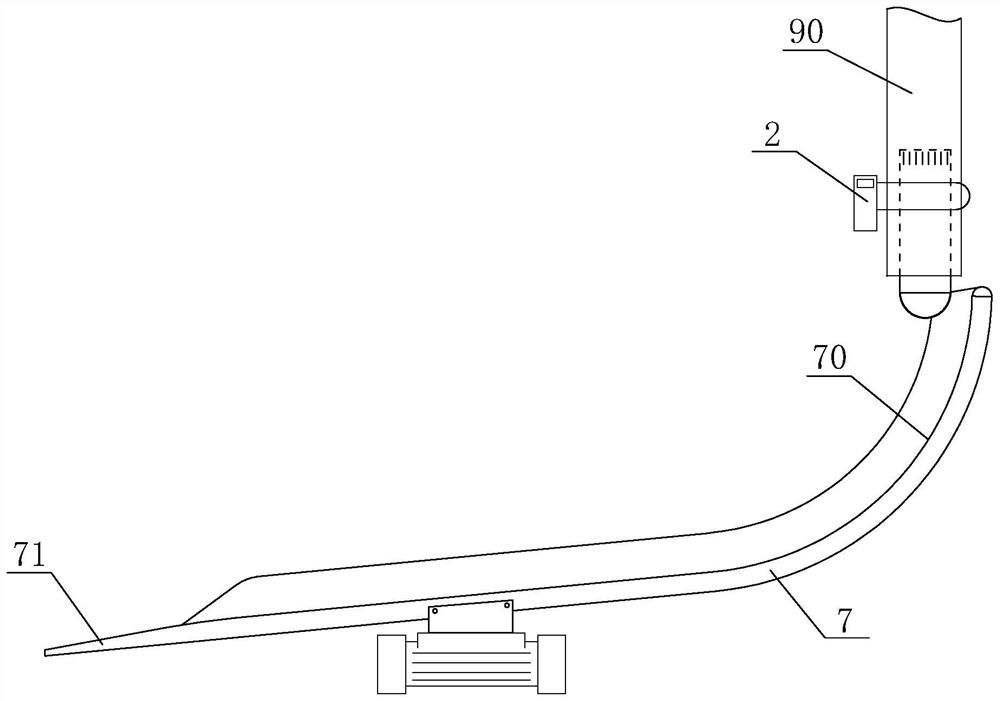

[0035] The sock body 10 sorting device i...

Embodiment 2

[0046] Such as Figure 15 As shown, the technical content of this embodiment is basically the same as that of Embodiment 1, and the technical points of difference between this embodiment and Embodiment 1 are:

[0047] The identification mark is a two-dimensional code that contains socks batch information, model information and size information printed on the cable tie 623, and the information of each sock can be entered into the computer of the factory through the two-dimensional code scanner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com