Kitchen garbage can full-automatic treatment system and process with movable deflection spraying part

A processing system and processing technology, which are applied to the automatic processing system and process field of kitchen waste trash cans with movable deflecting spray parts, can solve the problem that the kitchen waste processing requirements of urban households cannot be met, and the perishable odor of kitchen waste is not considered. , mixed solid and liquid, narrow application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0088]Example 1

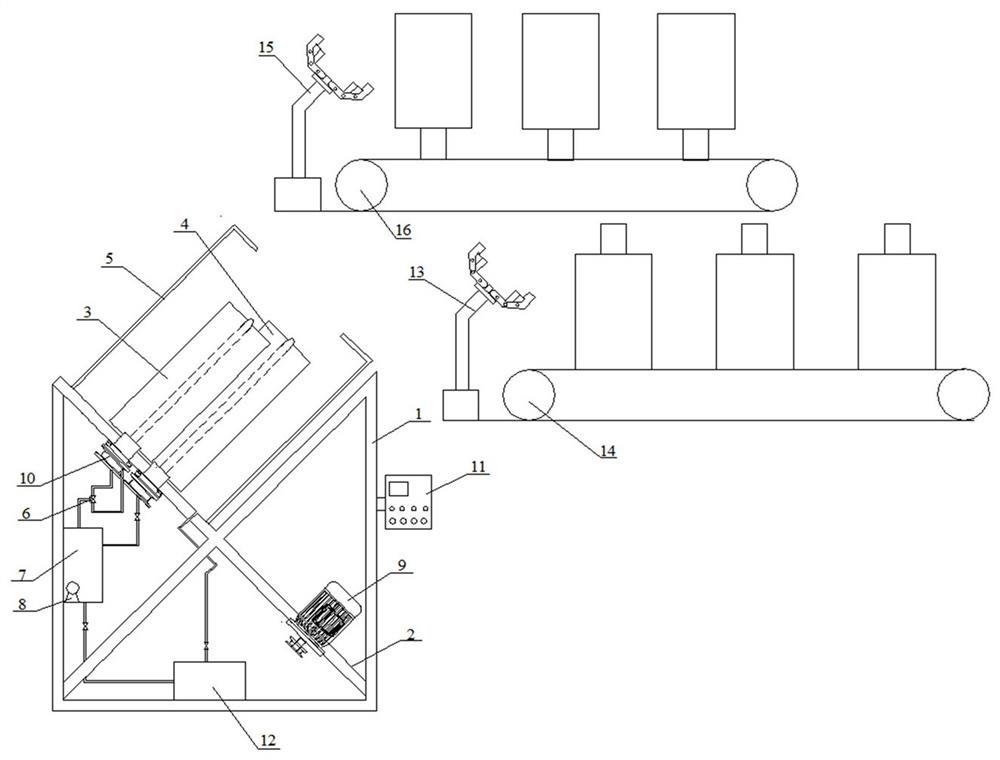

[0089]figure 1 A structural diagram showing the full automatic processing system of the kitchen trash can full automatic processing system with a sprayed spray member having an active deflection.

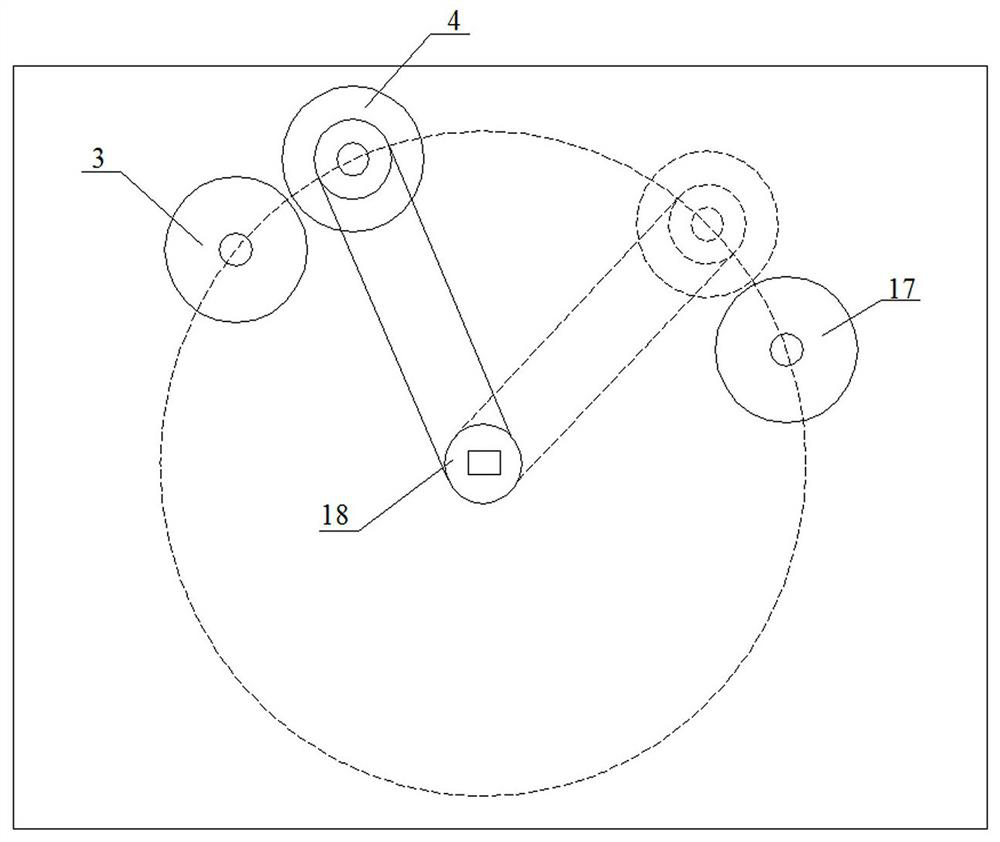

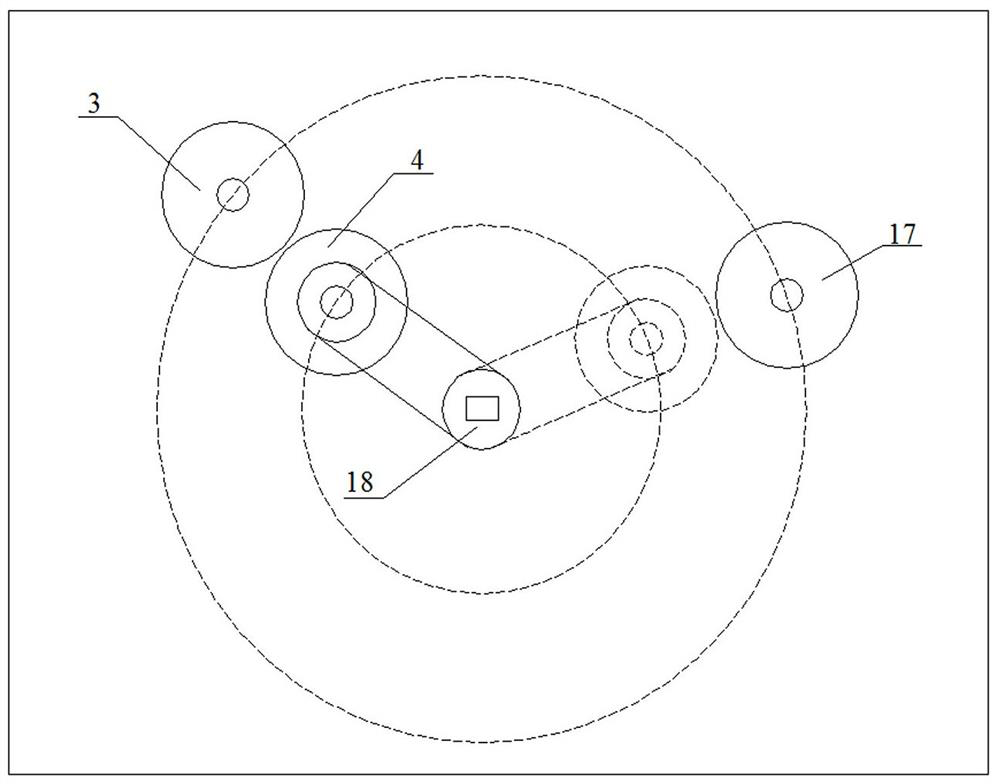

[0090]Figure 2A A mating mechanism of the first inner brush mechanism, the second internal brush mechanism, and the outer brush mechanism is shown, that is, the figure shows the top view of the gravity tilt direction (for example, the direction of the gravity tilt 45 °), A comparative relationship between an inner brush mechanism, the second internal brush mechanism, and the outer brush mechanism.Figure 2b Another mating mechanism of the first inner brush mechanism, the second internal brush mechanism, and the outer brush mechanism is shown, that is, the figure shows a top view of the gravity tilt direction (for example, the direction of the gravity tilt 45 °). Another mating relationship between the first inner brush mechanism, the second internal brush mechanism, and the out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap