Lithium carbon fluoride battery positive pole piece, preparation method thereof and lithium carbon fluoride battery

A technology of lithium fluoride carbon battery and positive electrode sheet, which is applied to the electrodes of primary batteries, electrode manufacturing, battery electrodes, etc., and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

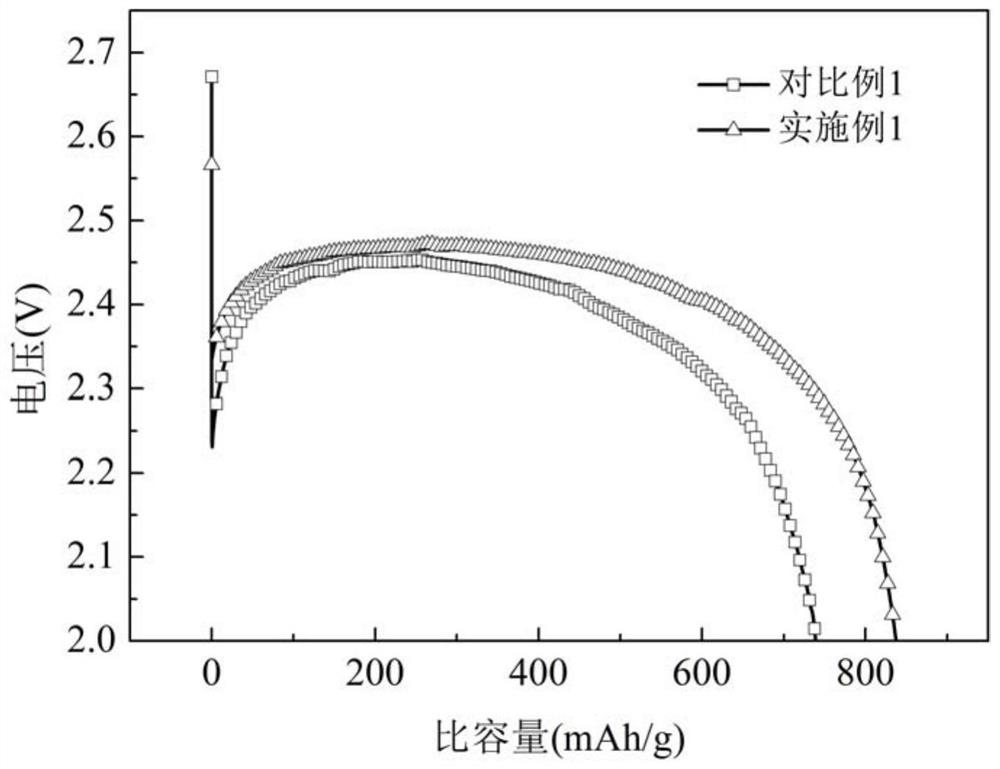

Embodiment 1

[0054] A preparation method of a lithium carbon fluoride battery positive pole piece:

[0055] (1) The fluorocarbon material (CF 0.99 ), binder (PVDF), conductive agent (SP and CNT mass ratio of 1:1), chloride (NaCl) and solvent (NMP) are mixed, wherein fluorinated carbon material: binder: conductive agent: chloride The mass ratio is 90:5:4.9:0.1, and the obtained viscosity is the positive electrode slurry of 10000MPa;

[0056] (2) Coating the positive electrode slurry on the current collector (aluminum foil) with a coating thickness of 160 μm, then adjusting the rolling temperature to 25° C. and the rolling pressure to 60 tons to obtain a compacted density of 1.6 g / cm 3 , to obtain a lithium carbon fluoride battery cathode sheet with a porosity of 28%.

Embodiment 2

[0058] A preparation method of a lithium carbon fluoride battery positive pole piece:

[0059] (1) The fluorocarbon material (CF 0.99 ), binder (PVDF), conductive agent (SP), chloride (KCl) and solvent (NMP) are mixed, wherein the mass ratio of fluorocarbon material: binder: conductive agent: chloride is 94.95:3: 2:0.05, the obtained viscosity is the positive electrode slurry of 17000MPa;

[0060] (2) Coating the positive electrode slurry on the current collector (aluminum foil) with a coating thickness of 150 μm, then adjusting the rolling temperature to 150° C. and the rolling pressure to 30 tons to obtain a compacted density of 1.4 g / cm 3 , to obtain a lithium carbon fluoride battery cathode sheet with a porosity of 48%.

Embodiment 3

[0062] A preparation method of a lithium carbon fluoride battery positive pole piece:

[0063] (1) The fluorocarbon material (CF 0.99 ), binder (PVDF), conductive agent (SP), chloride (KCl) and solvent (NMP) are mixed, wherein the mass ratio of fluorocarbon material: binder: conductive agent: chloride is 94.95:3: 2:0.05, the obtained viscosity is the positive electrode slurry of 17000MPa;

[0064] (2) Coat the positive electrode slurry on the current collector (aluminum foil) with a coating thickness of 150 μm, then adjust the rolling temperature to 61° C., and the rolling pressure to 50 tons to obtain a compacted density of 1.4 g / cm 3 , to obtain a lithium carbon fluoride battery cathode sheet with a porosity of 31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap