Mounting walking module of spacer installation and maintenance robot

A technology of robots and spacers, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of low installation efficiency, long installation tower distance, and high physical strength consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

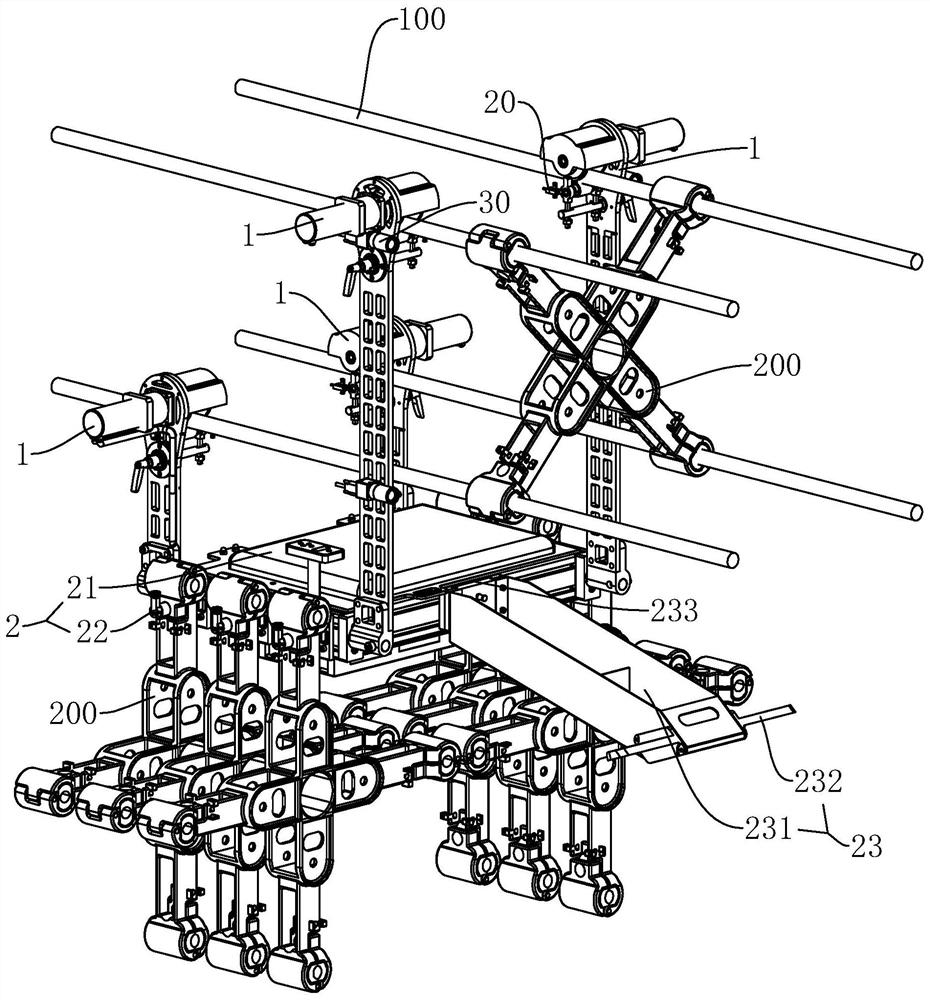

[0028] combine Figure 1 to Figure 7 Further description will be made on the mounted walking module of the spacer installation and maintenance robot of the present invention.

[0029] A spacer installation and maintenance robot is characterized in that it includes an operation support module 2 and a mounted walking module connected to the operation support module 2 .

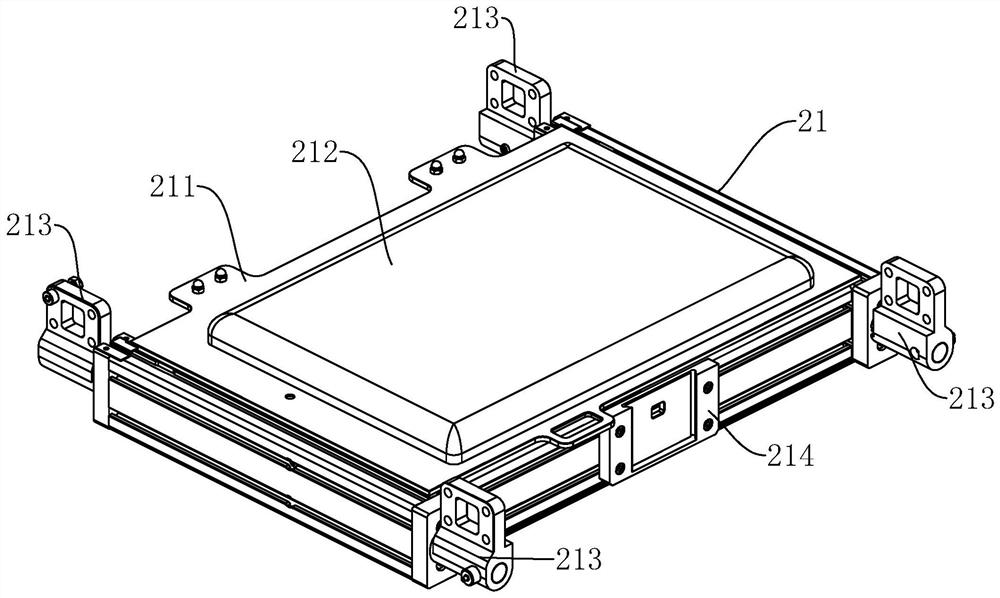

[0030] The work support module 2 has a seat frame 21 , a hanger assembly and a tool box 23 . The hanger assembly is installed on the left and right sides of the seat frame 21 and can be hung by a plurality of spacer bars 200 . The tool box 23 is installed on the front side of the seat frame 21 and can be placed and supported by the operator's feet.

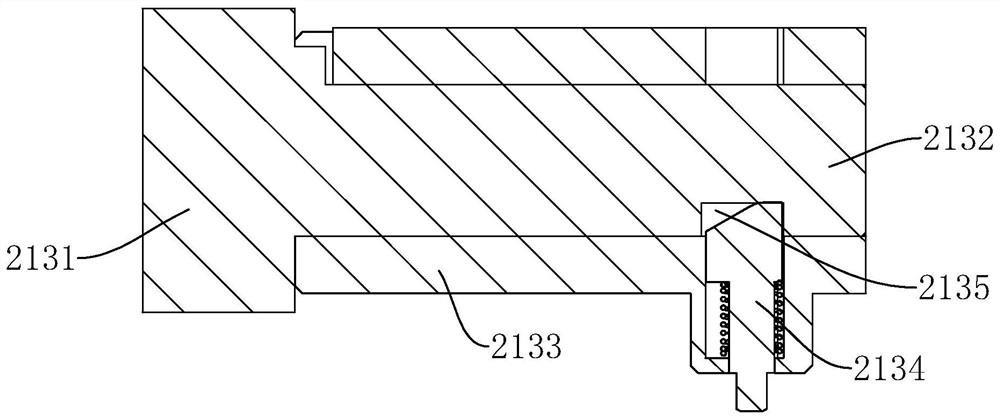

[0031] The mounted traveling module includes a plurality of mounted traveling devices 1 , and each mounted traveling device 1 includes a connecting arm 19 , traveling wheels 12 , a driving motor 11 and a wire locking mechanism 10 . Described traveling wheel 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com