Environment-friendly printing process, paperboard prepared by printing process and application of paperboard

An environmentally friendly and technological technology, applied in the field of cardboard printing, can solve problems such as printing errors and achieve the effect of easy detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

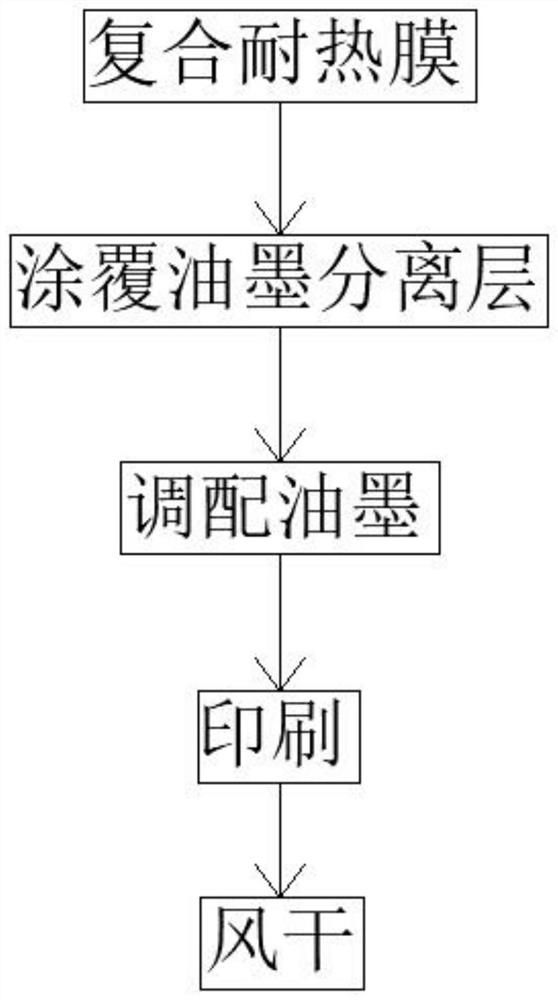

[0030] Such as figure 1 The environmentally friendly printing processes shown include:

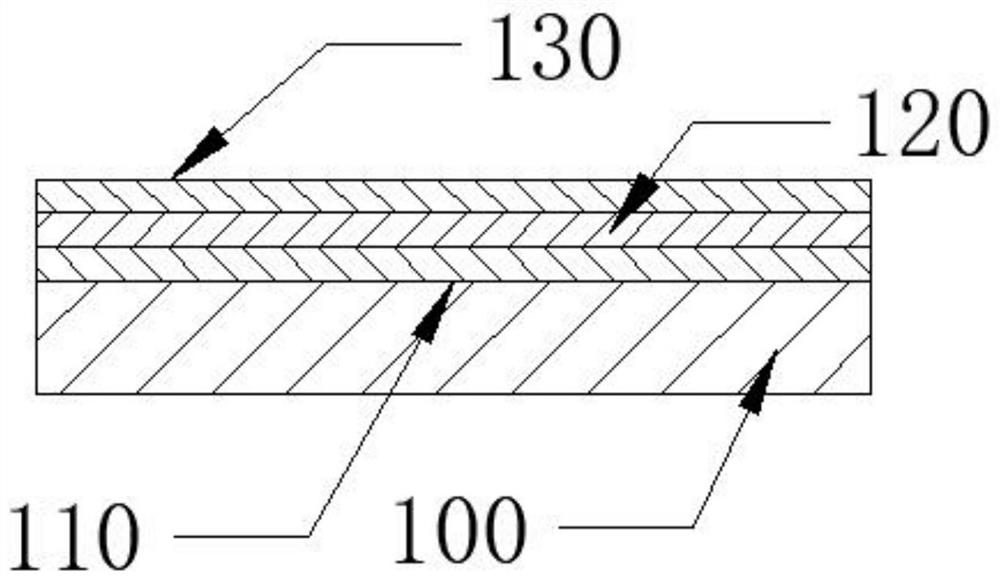

[0031] S1. Composite heat-resistant film 110: compound a layer of heat-resistant film 110 on the base paper layer 100. The specific heat-resistant film 110 is made of poly-4-methyl-1-pentene, and then coated with an acrylate adhesive Thermal film 110 is then placed on the composite matrix layer.

[0032] S2. Coating the ink separation layer 120: coat a layer of EVA resin on the heat-resistant film 110, and then cool to form the ink separation layer 120. Specifically, heat and stir the EVA resin masterbatch. When the temperature reaches between 100-110°C At this time, it is coated on the heat-resistant film 110, and then waits for natural cooling to form a layer of ink separation layer 120 on the surface of the heat-resistant film 110.

[0033] S3. Prepare ink: add rosin-modified phenolic resin, soybean oil, and mineral oil to mix, then heat to 125-145°C, and stir for 1 hour, then add ant...

Embodiment 2

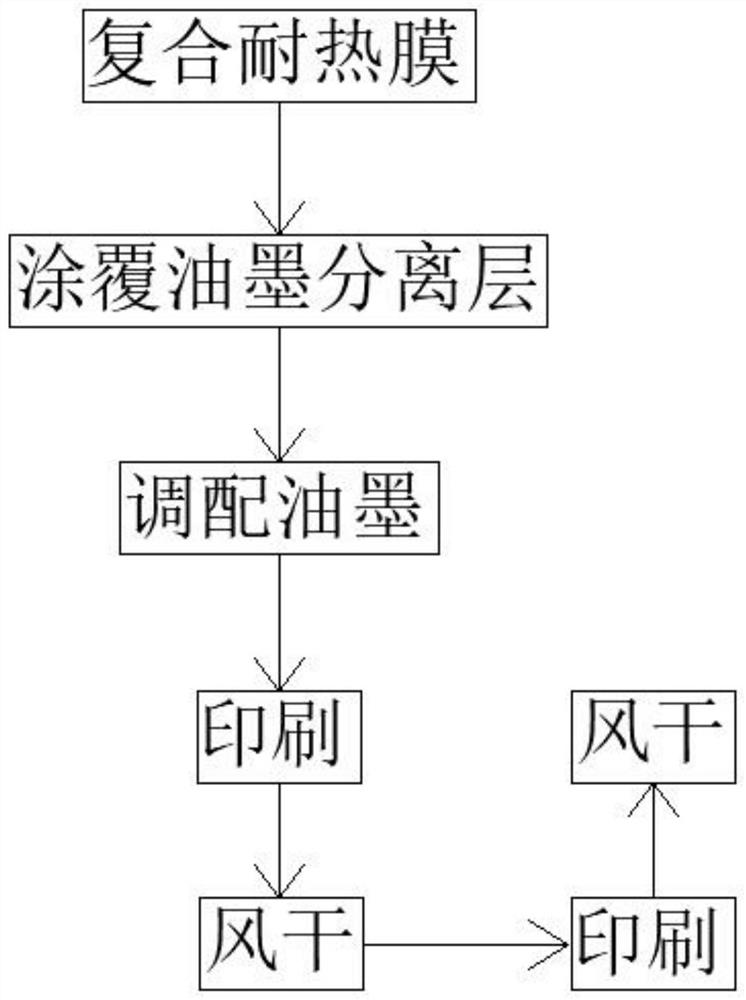

[0041] Such as image 3 Shown, environmentally friendly printing processes, including:

[0042] S1. Composite heat-resistant film 110: A layer of heat-resistant film 110 is compounded on both sides of the base paper layer 100. Specifically, the heat-resistant film 110 is coated with an acrylate adhesive, and then laminated on the matrix layer.

[0043] S2. Coating the ink separation layer 120: apply a layer of EVA resin on the heat-resistant film 110 on both sides, and then cool to form the ink separation layer 120. Specifically, heat and stir the EVA resin masterbatch. When the temperature reaches 100- When the temperature is between 110°C, it is coated on the heat-resistant film 110, and then waits for natural cooling to form a layer of ink separation layer 120 on the surface of the heat-resistant film 110.

[0044] S3. Prepare ink: add rosin-modified phenolic resin, soybean oil, and mineral oil to mix, then heat to 125-145°C, and stir for 1 hour, then add antioxidant and d...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 or 2 is that after step S5 is completed, a protective film is coated on the ink layer 130, and then air-dried. The specific protective layer 131 is coated with ethyl α-cyanoacrylate form.

[0055] Such as Figure 5 As shown, the cardboard manufactured by the environmentally friendly printing process of this embodiment is coated with a protective layer 131 on the outside of the ink layer 130 to protect the ink and avoid damage to the ink layer 130 due to long-term friction, thereby causing damage to the ink layer 130. Discoloration, etc. will occur.

[0056] The cardboard produced by the environmentally friendly printing process of this embodiment can be used as board game props, such as board game cards, chess boards, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com