Liquid separator, compressor, air conditioner

A technology for liquid separators and compressors, which is applied in the fields of liquid separators, compressors, and air conditioners. It can solve problems that affect the energy efficiency and reliability of compressors, reduce compressor reliability, and reduce compressor energy efficiency. Thermal performance and operating reliability, improving energy efficiency and operating reliability, and improving the effect of refrigerant mass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

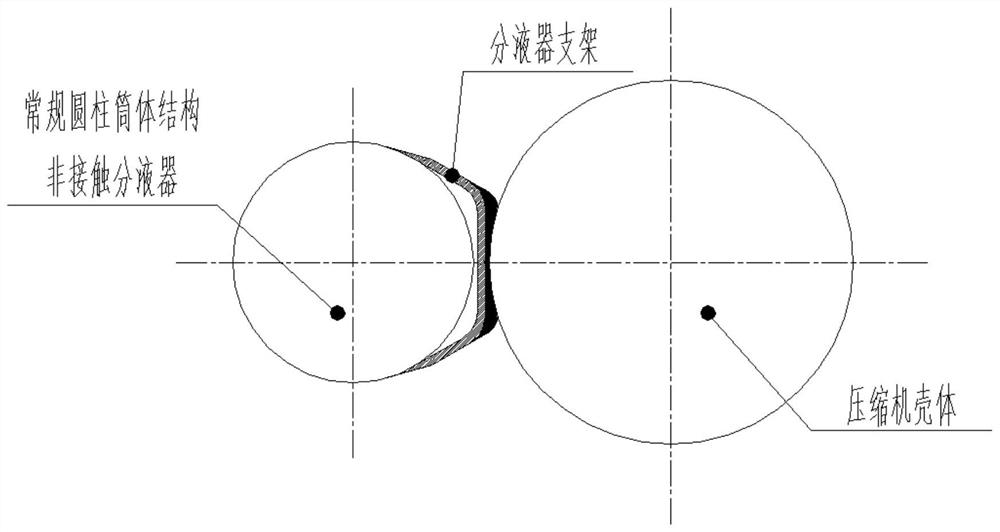

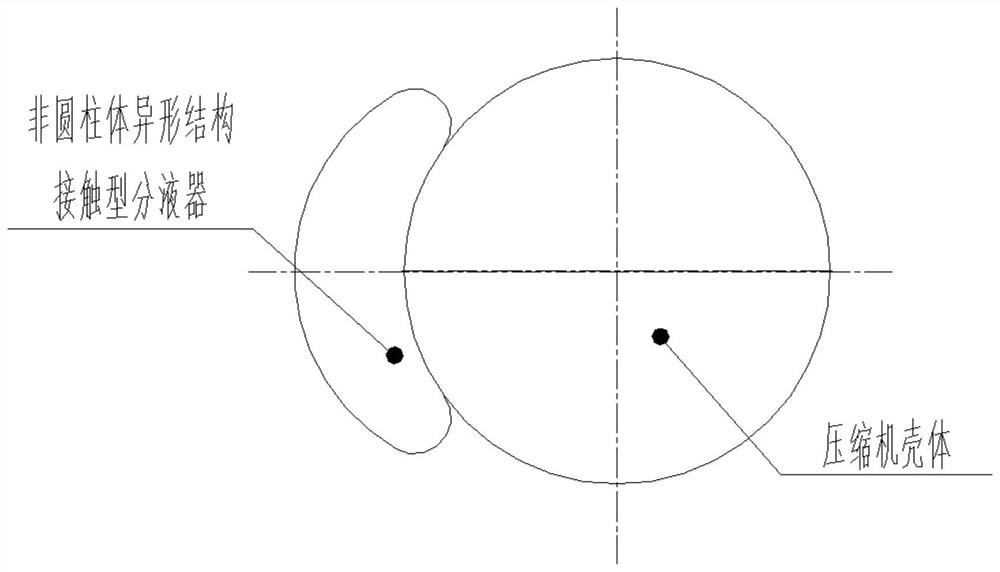

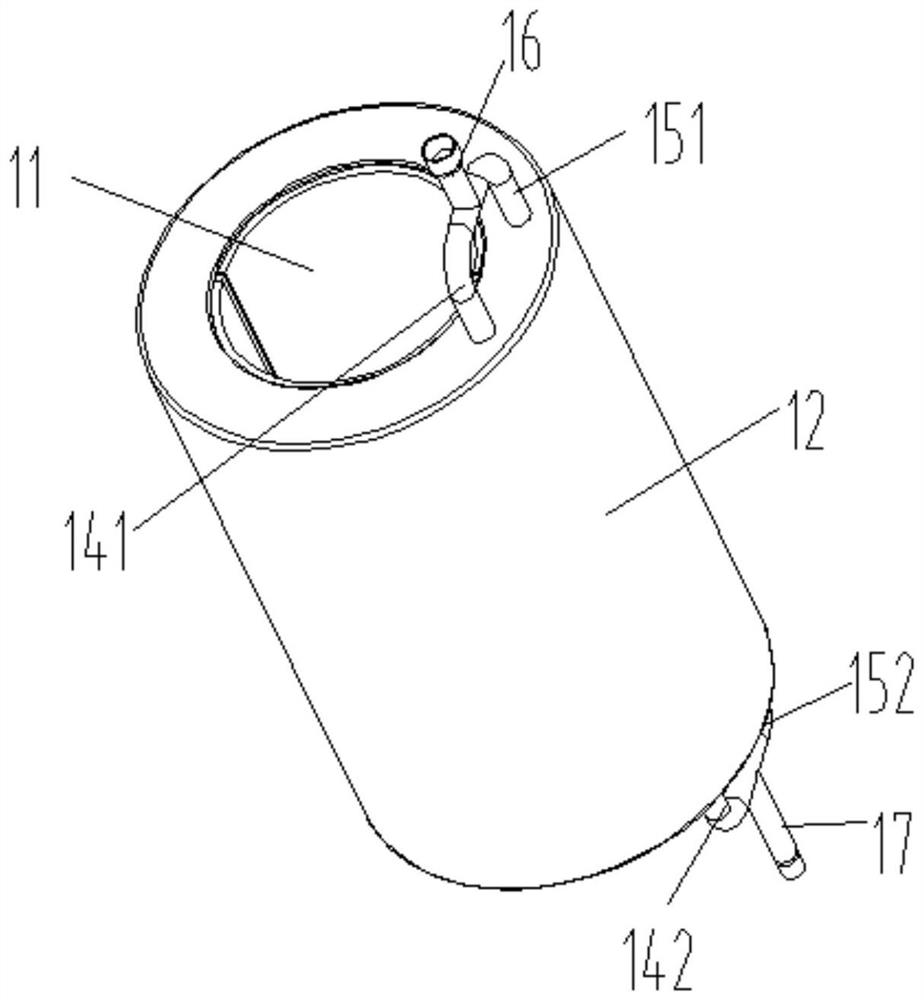

[0037] see in conjunction Figure 1 to Figure 11As shown, according to an embodiment of the present invention, a liquid separator is provided, including a first ring wall 11 and a second ring wall 12 radially outside the first ring wall 11, the first ring wall 11 A liquid separation space is formed between the second ring wall 12 (it can be understood that it is provided with corresponding sealing plates at both ends of the length of the first ring wall 11 and the second ring wall 12, so that The liquid-separating space becomes a closed space), the liquid-separating space is provided with a separator 13 (such as a partition), and the liquid-separating space is separated into a first liquid-separating chamber 14 and a second liquid-separating chamber independent of each other. 15, wherein, the first liquid separation cavity 14 corresponds to the first wall area of the first ring wall 11, and the first wall area can perform heat exchange with the shell of the compressor 100, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com