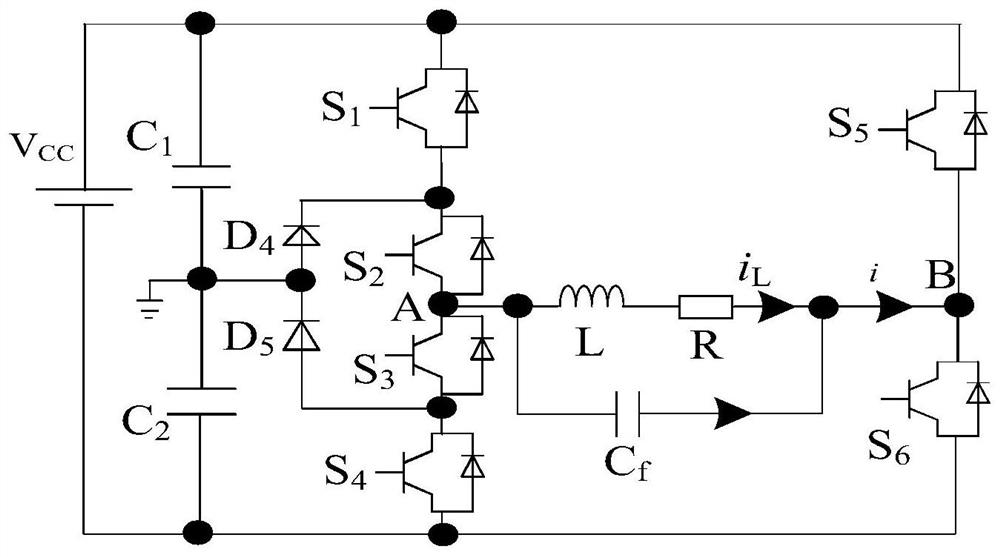

Composite three-level double-buck inverter, and control method and system thereof

A control method and inverter technology, applied in the direction of electrical components, AC power input conversion to DC power output, output power conversion device, etc., can solve high reverse recovery loss, increase grid-connected current harmonic content, reduce Inverter power quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

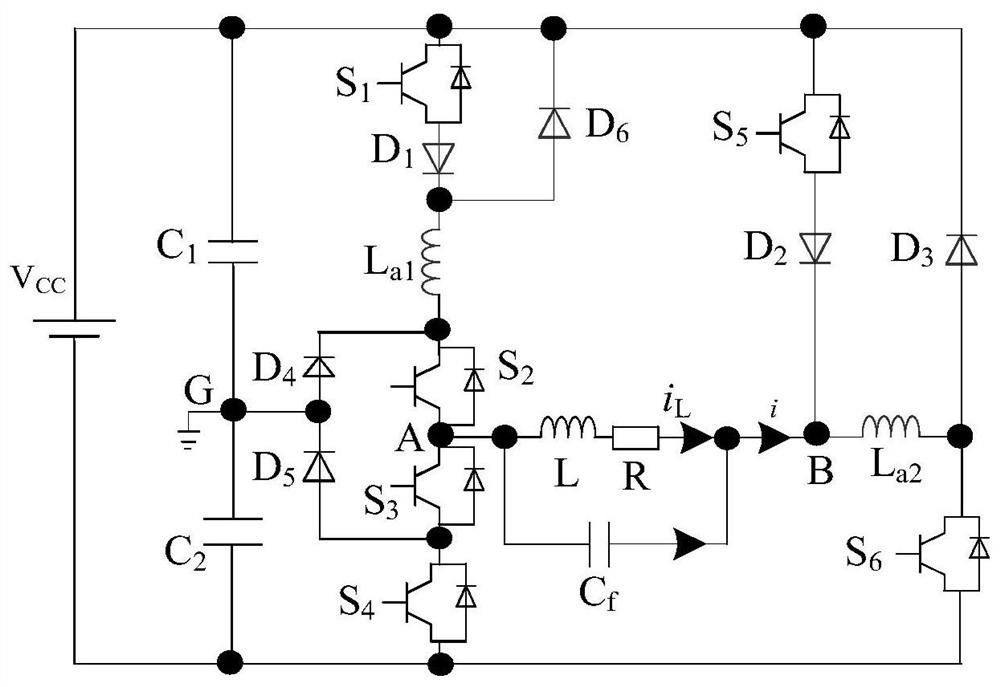

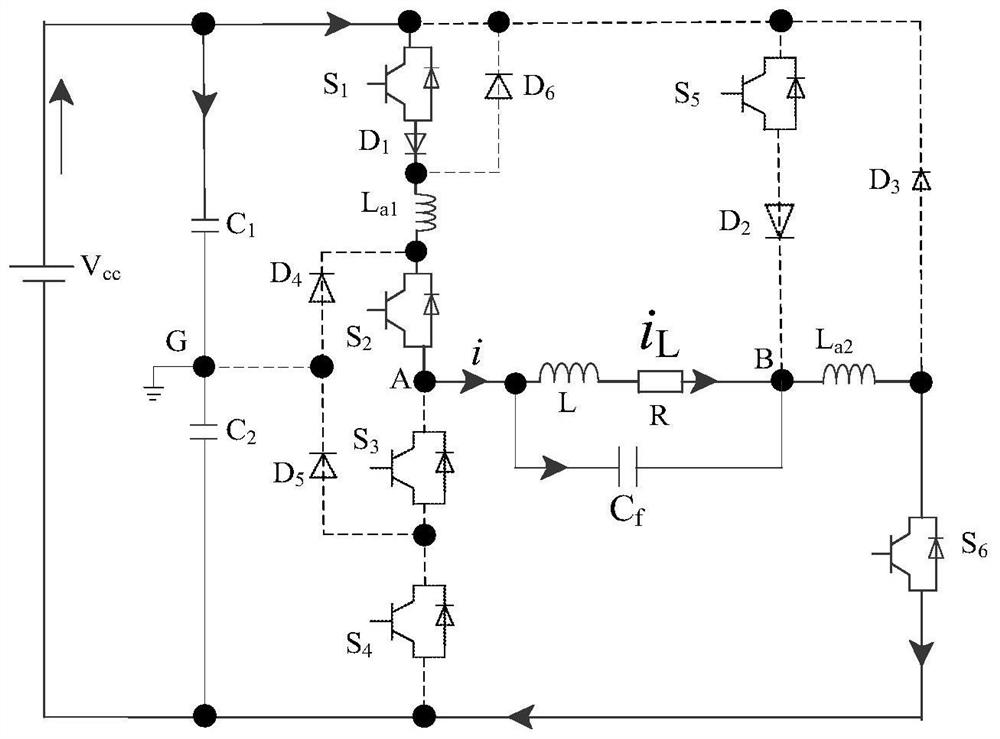

[0053] A compound three-level double-buck inverter, such as figure 2 As shown, the inverter is mainly composed of DC voltage source Vcc, supporting capacitor C 1 , support capacitance C 2 , power switch tube S 1 , power switch tube S 2 , power switch tube S 3 , power switch tube S 4 , power switch tube S 5 , power switch tube S 6 , power diode D 1 , power diode D 2 , power diode D 3 , power diode D 4 , power diode D 5 , power diode D 6 , filter inductance L a1 , filter inductance L a2 , filter inductor L and filter capacitor C f And the composition of the load resistance R;

[0054] where the support capacitor C 1 One end of the DC voltage source Vcc is connected to the positive pole of the support capacitor C 1 The other end of the support capacitor C 2 One end of the connection, support capacitor C 2 The other end of the DC voltage source Vcc is connected to the negative pole;

[0055] Power switch tube S 1 The collector of the DC voltage source Vcc is ...

Embodiment 2

[0064] In this embodiment, the unipolar dual-carrier modulation method is used to control the working mode of the composite three-level double-buck inverter proposed in the above-mentioned embodiment 1. During specific implementation, the Figure 9 shown in the modulation method and Figure 10 The logic control diagram shown in the figure realizes the power switch tube S 1 , power switch tube S 2 , power switch tube S 3 , power switch tube S 4 , power switch tube S 5 and the power switch tube S 6 on or off. The existing SPWM control principle is to use a reference sine wave and a triangular carrier wave for handover to obtain a pulse signal, which is used to control the switching of the power switch tube. However, the five-level inverter of this application needs to modulate the signal u c After rectification, the triangular carrier V with two frequencies and amplitudes equal C1 and V C2 compared to obtain two pulse signals A 1 and B 1 . Simultaneously with modulat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap