Blasting dust fall air bag watering device

A sprinkler and airbag technology, applied in blasting, blasting tubes, using liquid separation agents, etc., can solve problems such as failure to achieve green construction, health damage to residents and construction workers, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

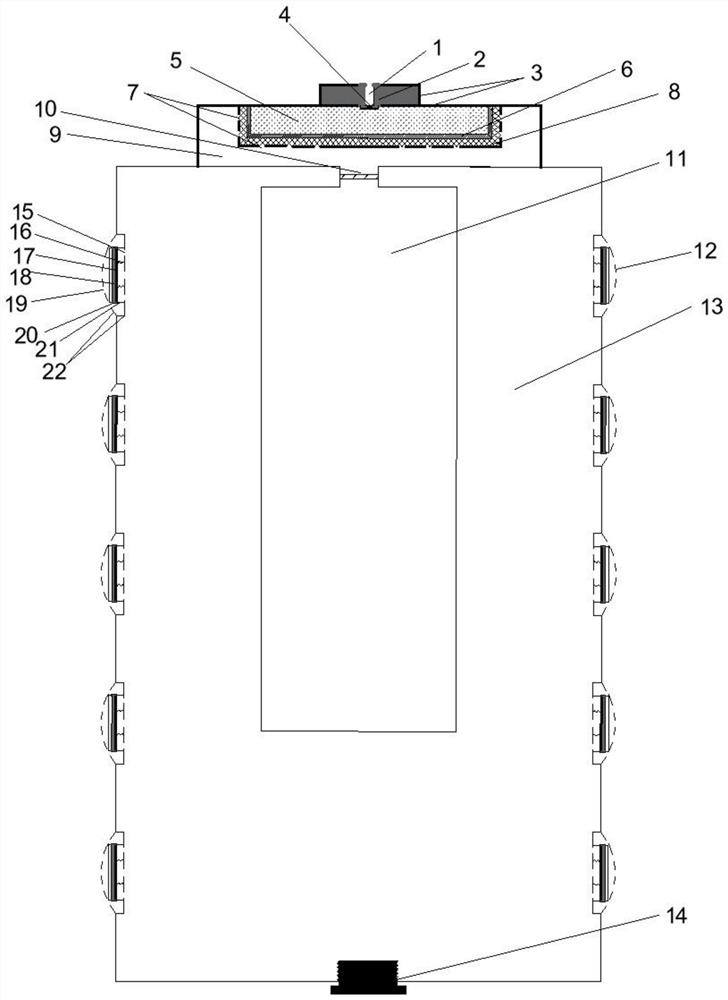

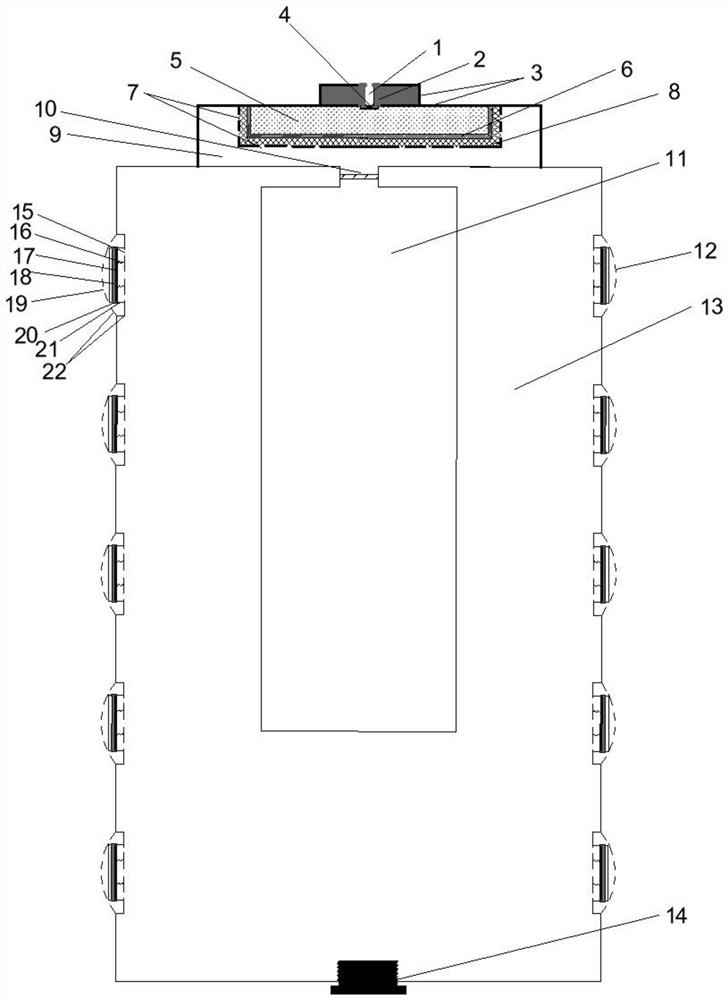

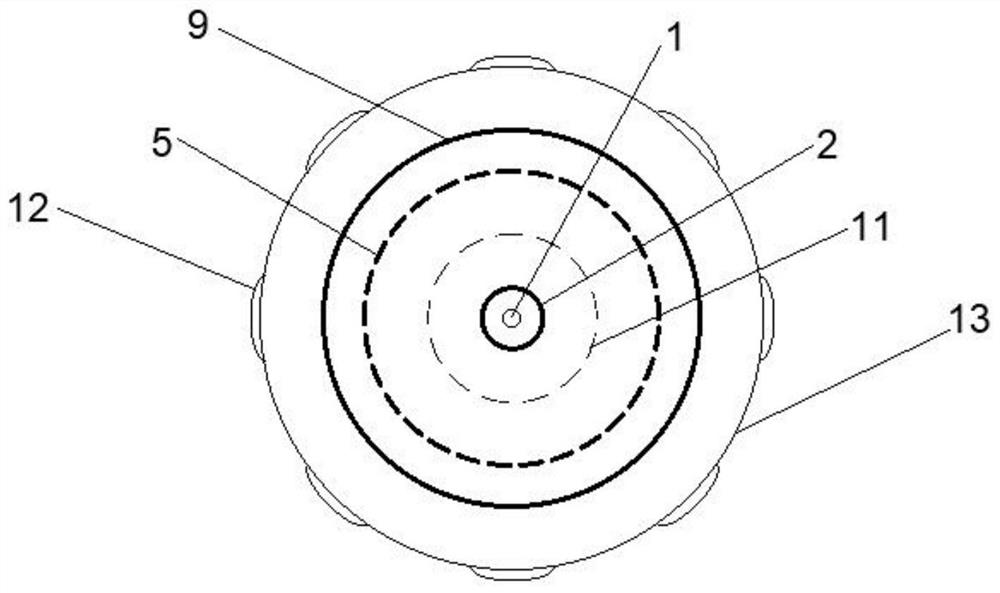

[0021] In the blasting and demolition of a building, the water inlet cover 14 is unscrewed, and an appropriate amount of water is filled into the water storage bag 13. In the stage of detonation network connection, several devices are placed on columns, shear walls, and floors containing blast holes. For beams and other locations where smoke and dust are likely to be generated, insert the nonel into the nonel insertion channel 1, and use the cross to connect to the detonation network together. In this way, while detonating, the detonator ignites the gas generating agent 5, and its reaction chemical equation is: 8CH 3 N 5 +7KClO 4 =7KCl+8CO 2 +12H 2 O+20N 2 , the gas generating agent 5 reacts rapidly after being ignited to generate carbon dioxide, water vapor and nitrogen. Under standard conditions, 1 g of the gas generating agent produces about 0.542 L of gas, which is instantly filled into the elastic air storage bag 11 and stored under the action of expansion. The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com