Inspection and classification device and method for metal mask strips

A technology of metal mask and sorting equipment, which is applied in sorting and other directions, and can solve problems such as low netting yield, offset of opening position, deformation of metal mask plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

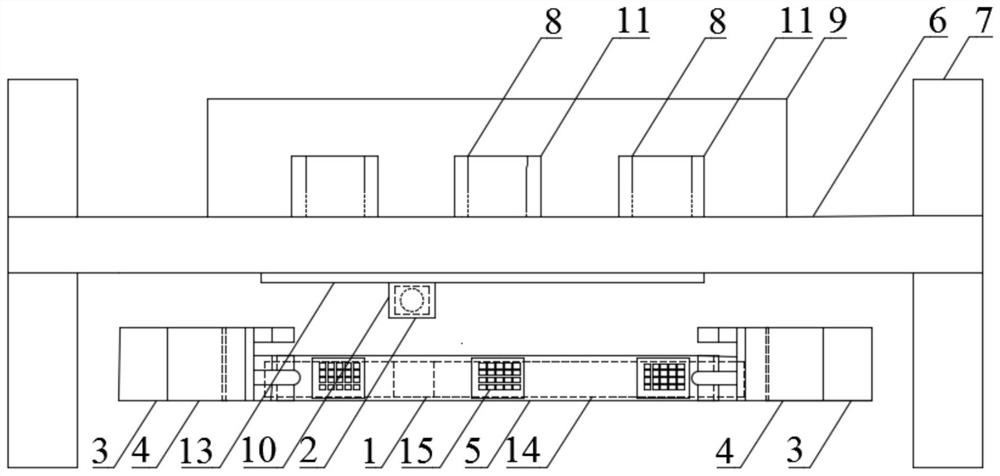

[0071] Please refer to figure 2 , Figure 5 to Figure 7 , Embodiment 1 of the present invention is:

[0072] An inspection and sorting device for metal mask strips, such as figure 2 As shown, it includes a backlight 1 , a position measuring device 2 , a first track 3 and a clamping device 4 . Wherein, the position measuring device 2 is erected above the backlight 1 , and the measuring direction of the position measuring device 2 is aligned with the light emitting surface of the backlight 1 . Both sides of the backlight 1 are provided with a clamping device 4 respectively, the clamping device 4 is erected on the first track 3 and equipped with a tension sensor, the track direction of the first track 3 is the same as the placement direction of the two clamping devices 4 . The two clamping devices 4 are respectively used to clamp the two ends of the metal mask strip 5 to be tested, and the tension sensor is used to measure the tension of the metal mask strip 5 to be tested....

Embodiment 2

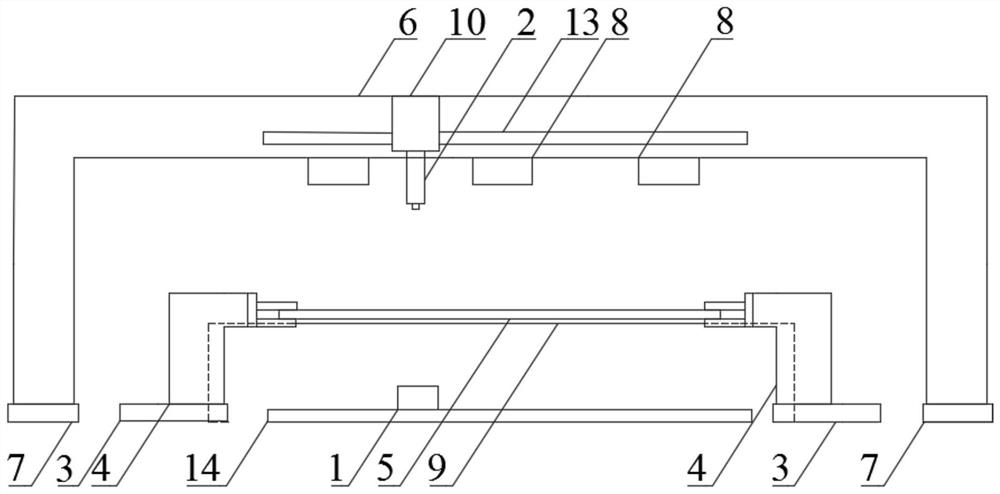

[0074] Please refer to Figure 1 to Figure 4 , the second embodiment of the present invention is:

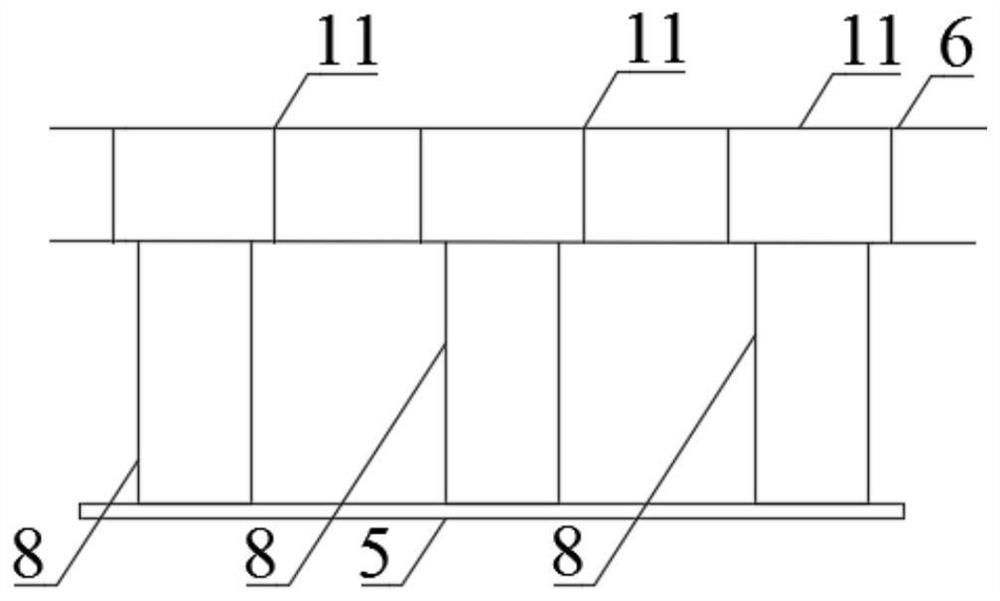

[0075] An inspection and sorting device for metal mask strips, such as figure 1 and figure 2 As shown, it also includes a gantry frame 6, a second rail 7, an adsorption device 8, a placement table 9, a first lifting device 10 and a second lifting device 11. Wherein, the placement table 9 and the backlight source 1 are located between the two second rails 7, the gantry frame 6 is erected on the two second rails 7, and the track direction of the second rail 7 is aligned with the arrangement direction of the placement table 9 toward the backlight source 1 same. The first lifting device 10 and the second lifting device 11 are erected respectively on the beam frame of the gantry 6, the position measuring device 2 is fixedly connected with the first lifting device 10, the adsorption device 8 is fixedly connected with the second lifting device 11, and the adsorption device 8 It is...

Embodiment 3

[0079] Please refer to Figure 8 , Embodiment three of the present invention is:

[0080] A method for checking and classifying metal mask strips, applied to the inspection and sorting equipment for a metal mask strip described in embodiment one or two, comprising steps:

[0081] S1, fixing the metal mask strip 5 to be tested and stretching the net, recording the current tension of the metal mask strip 5 to be tested;

[0082] S2, measuring the current opening position of the target opening 15 on the metal mask strip 5 to be tested at this time;

[0083] S3 , classifying the metal mask strips 5 to be tested according to the current tension corresponding to the metal mask strips 5 to be tested and the current opening positions.

[0084] In this embodiment, a method for checking and classifying metal mask strips is provided, by obtaining the current tension and the current opening position of the metal mask strip 5 to be tested in the current stretching state, and classifying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com