A grab ship unloader hopper anti-blocking system

A ship unloader and hopper technology, which is applied to conveyor objects, loading/unloading, conveyor control devices, etc., can solve the problem of increased workload in operation and maintenance, increase in terminal operation and maintenance costs, and affect the normal operation of grab ship unloaders, etc. problems, to reduce the risk of hopper blockage, easy operation, and ensure the safety of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

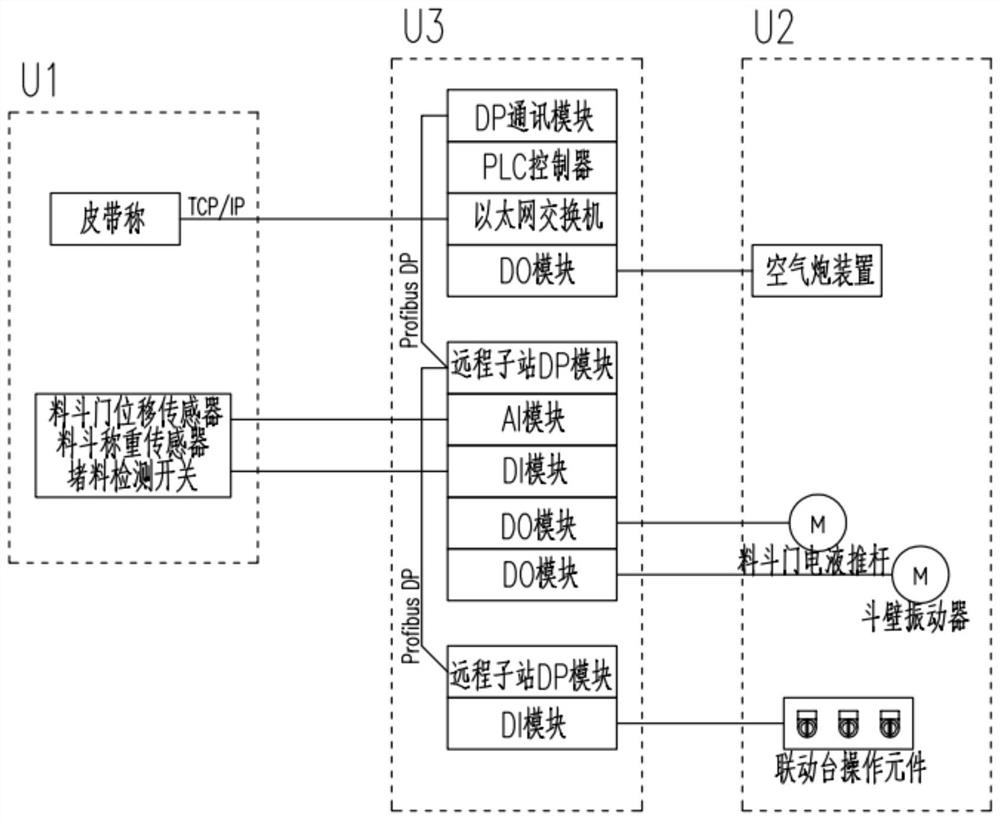

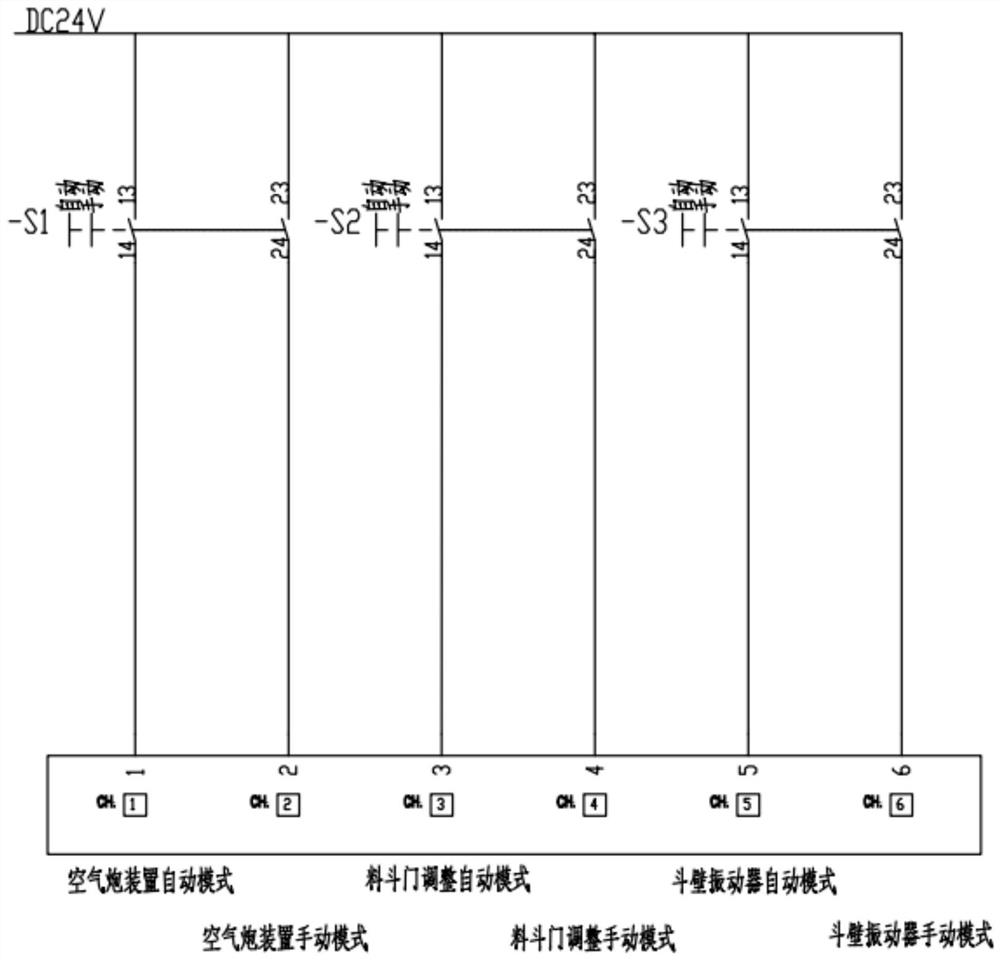

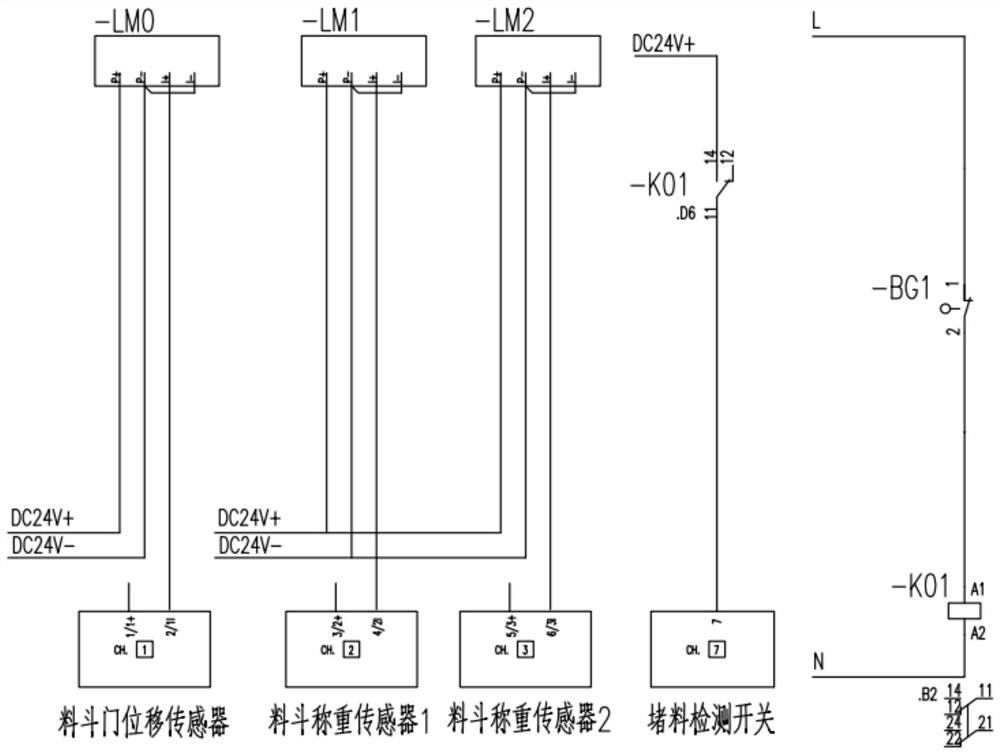

[0056] Taking the grab ship unloader equipped with bucket wall vibrator, air cannon and belt scale as an example, the anti-blocking function of its hopper is explained. control flow such as Figure 8 Shown: After the hopper anti-blocking function is applied, the PLC control unit firstly confirms the operating status of the air cannon, hopper door and bucket wall vibrator in the blocking treatment system. If it is confirmed that the operation is normal, the hopper anti-blocking function will be activated. activation. After the hopper anti-blocking function is activated, the PLC control unit will monitor the material blockage in the hopper area in real time. When the material blockage warning system of the hopper has a blockage warning (the blockage detection switch is activated, the material flow of the belt scale is abnormally reduced, and the decreasing trend of the hopper weight disappears) When the PLC control unit issues an instruction, the hopper blockage processing syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com