Screen plate structure, screening device and crushing device

A technology of sieve plate and screening unit, which is applied in the direction of sieve, solid separation, grid, etc., can solve the problems of clogging of sieve plate, reduction of porosity of sieve plate, reduction of screening efficiency, etc., so as to achieve less material blocking and high work efficiency. , the effect of improving the screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

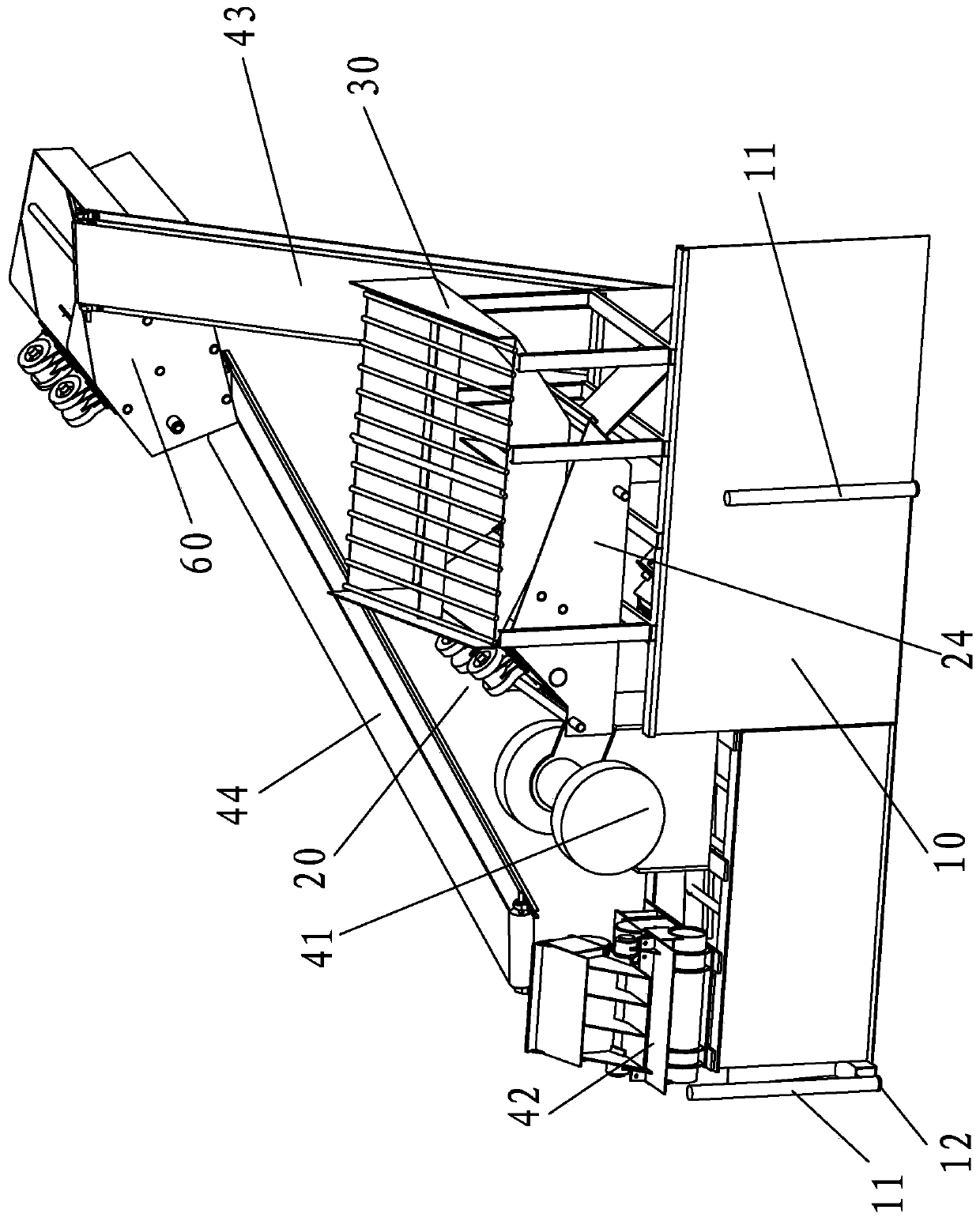

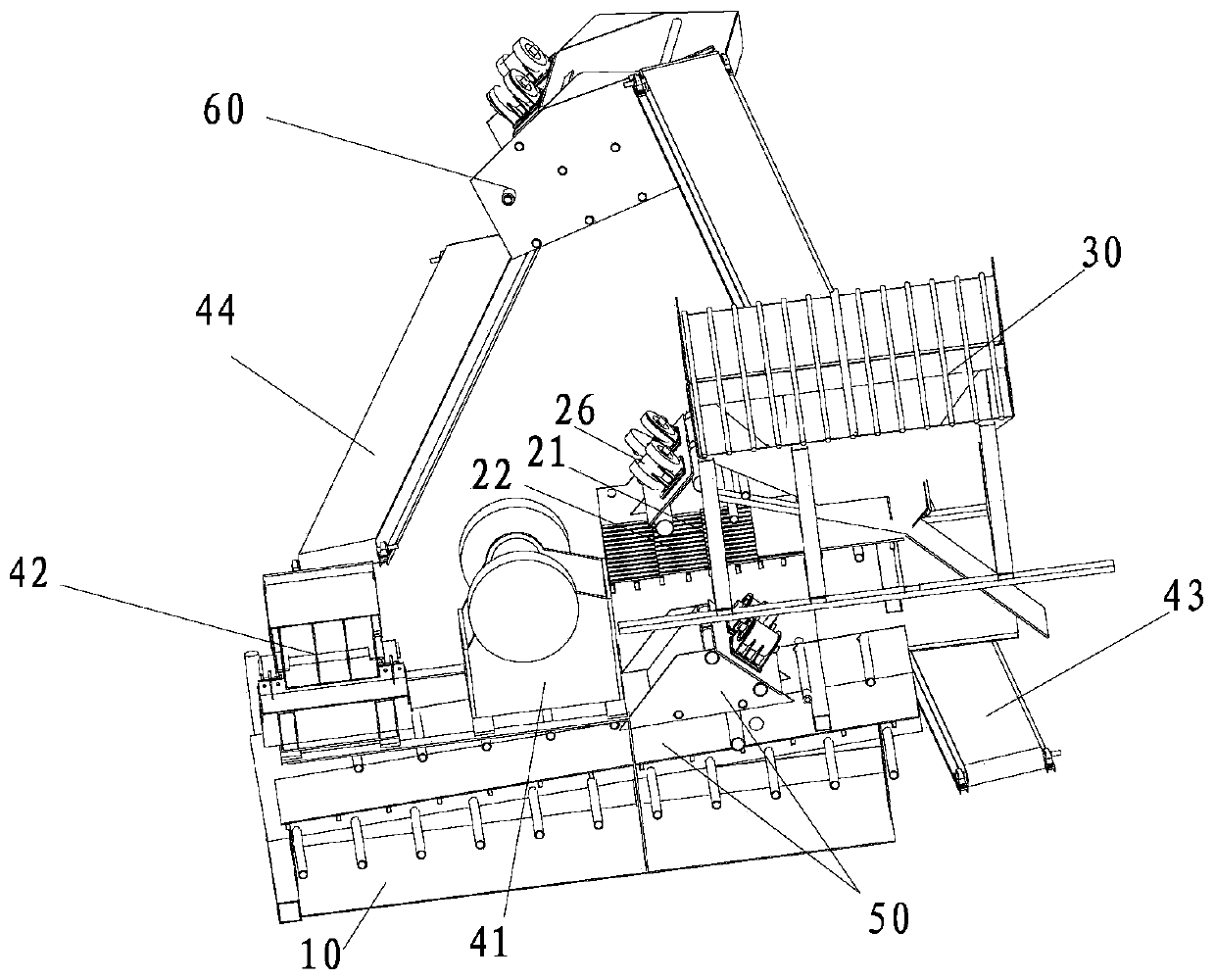

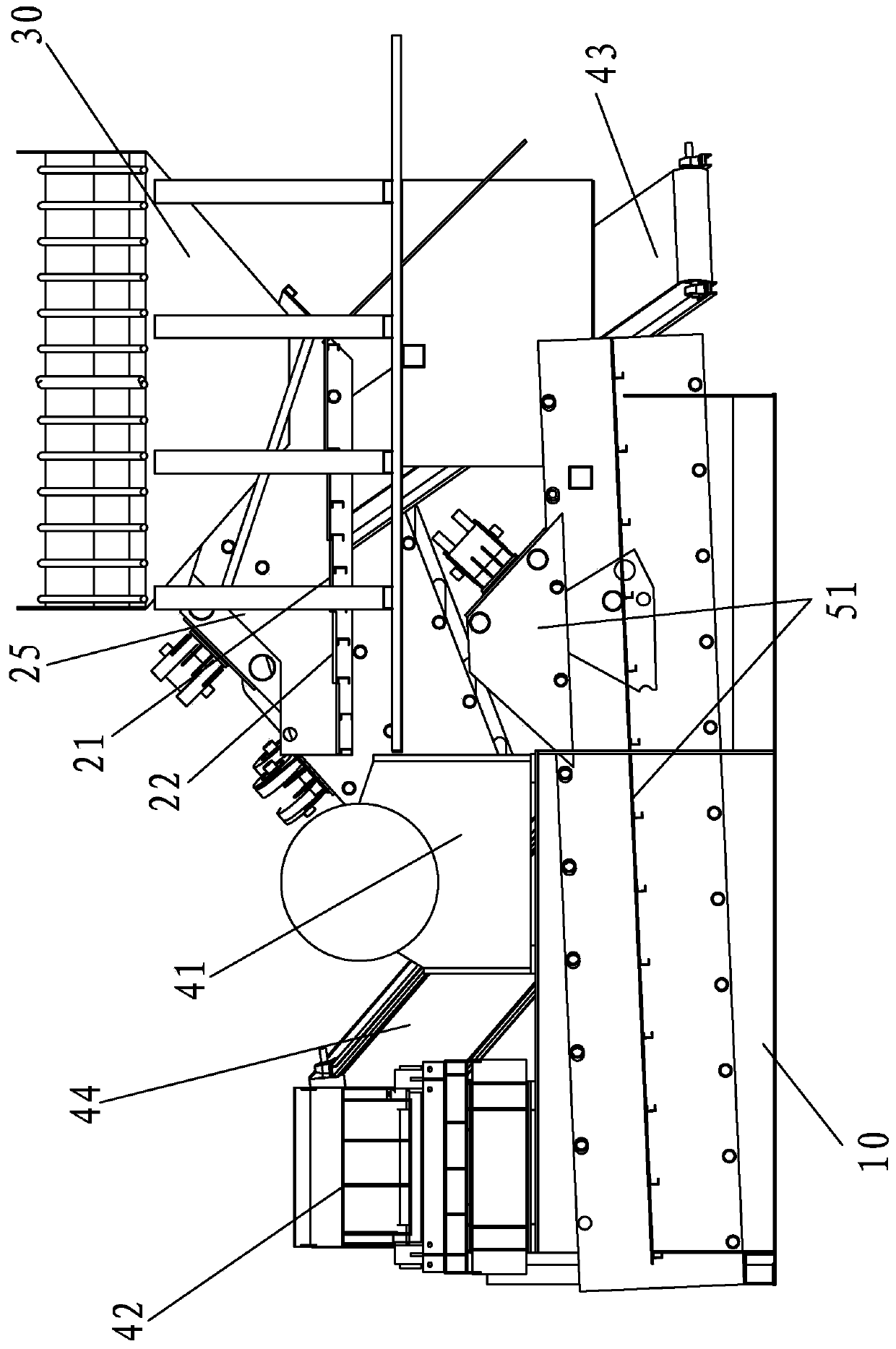

[0044] refer to Figure 1 to Figure 7 , the sieve plate structure, including a screening unit, the screening unit includes a plurality of sieve bars and connecting pieces for connecting the sieve bars into a sieve body 210, the sieve body 210 can be arranged in the horizontal direction, or can be arranged inclined relative to the horizontal plane, adjacent sieves Screening slots 215 are formed between the strips. The plurality of sieve bars at least includes a first sieve bar 213 and a second sieve bar 214 , and the plurality of sieve bars are arranged horizontally to form a sieve body 210 in the present invention. The screening groove 215 penetrates from the upper surface of the sieve body 210 to the lower surface, the first sieve bar 213 is provided with a first trough wall 2131 and a second trough wall 2132 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com