Curtain wall system

A curtain wall and curtain wall panel technology, applied in the field of curtain wall systems, can solve problems such as difficulty in forming steel keels, affecting the visual effect of the overall curtain wall, and discontinuity of the bearing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

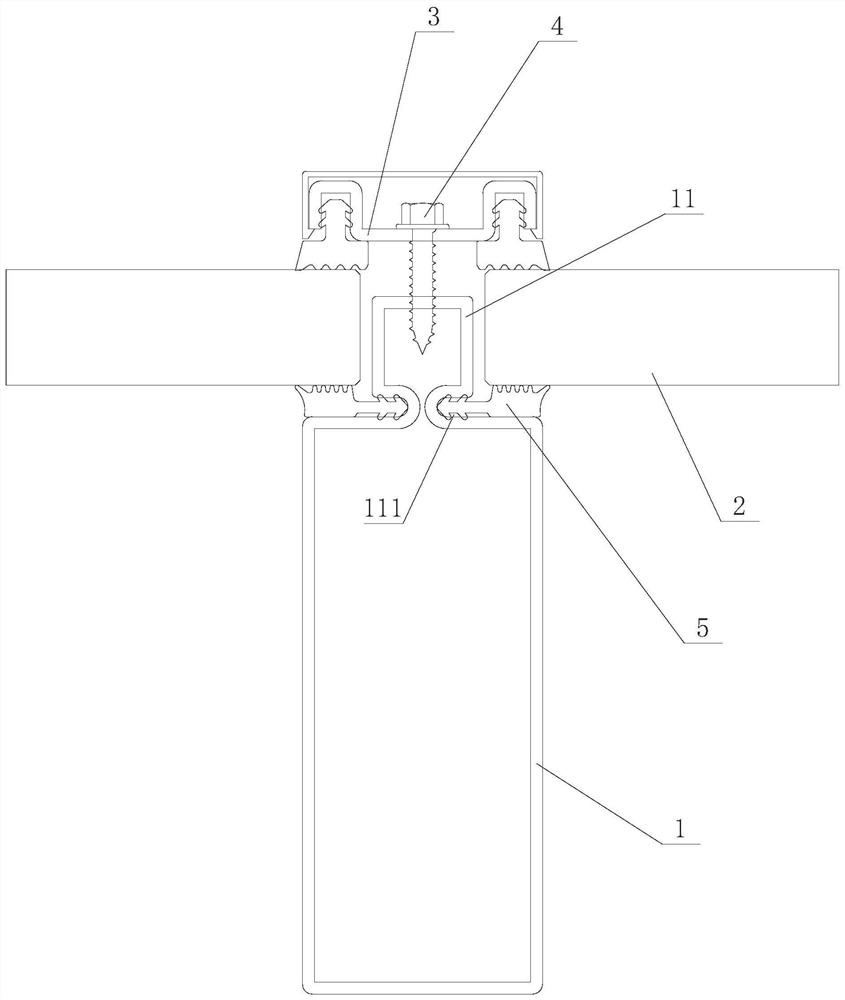

[0023] Such as figure 1 As shown, the first embodiment of the curtain wall system of the present invention includes a keel 1, a curtain wall panel 2, a pressure plate 3 and a locking bolt 4. The keel 1 is formed with a boss 11 extending out of the outline of the main body of the keel 1 on the bearing surface. , the curtain wall panel 2 is loaded on the bearing surface of the keel 1, the pressure plate 3 is pressed on the curtain wall panel 2, the locking bolt 4 is penetrated on the pressure plate 3 and is tightly connected with the boss 11, the curtain wall panel 2 and the keel 1 A sealing rubber strip 5 is provided, and a sinking groove 111 for preventing the sealing rubber strip 5 from falling off is formed on the boss 11 . During installation, the sealing rubber strip 5 is first clamped in the sinking groove 111, and the sealing rubber strip 5 covers the bearing surface of the keel 1, then the curtain wall panel 2 is loaded on the sealing rubber strip 5, and then the pressu...

Embodiment 2

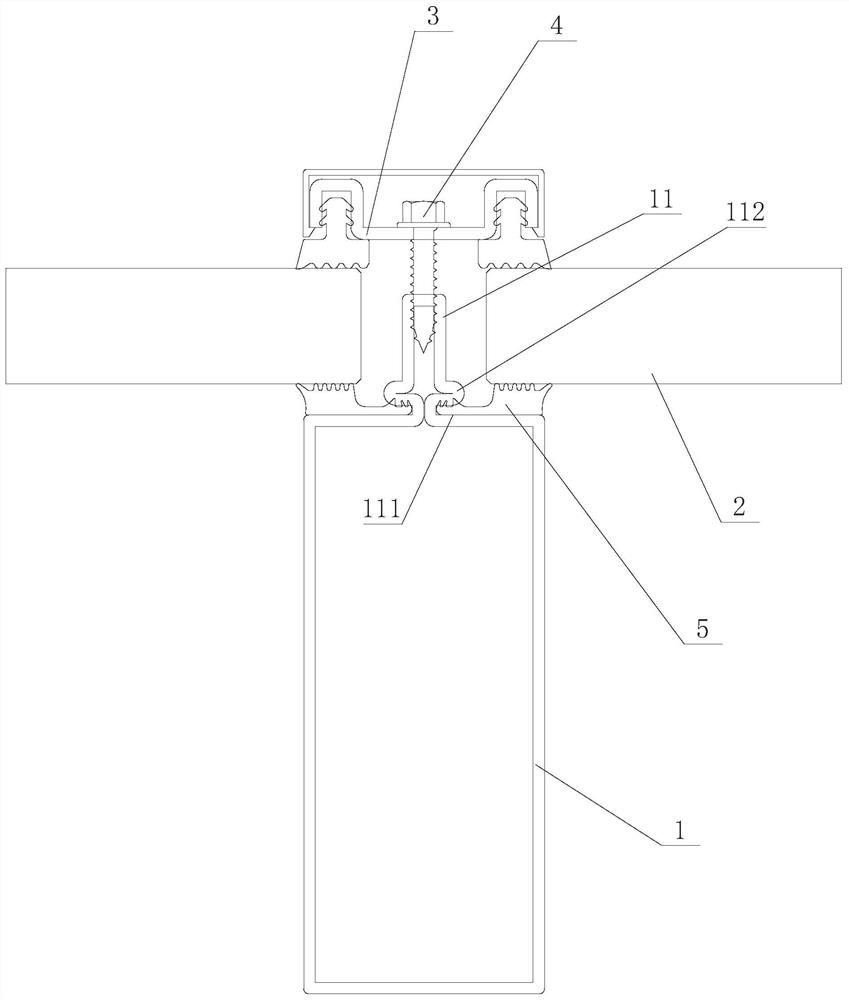

[0028] Such as figure 2 As shown, the second embodiment of the curtain wall system of the present invention, the curtain wall system is basically the same as Embodiment 1, the only difference is that in this embodiment, a lateral protrusion is formed on the boss 11 above the sinking groove 111 112. The arrangement of the lateral protrusions 112 strengthens the sinking groove 111 and the boss 11 at the same time, improving the connection strength.

Embodiment 3

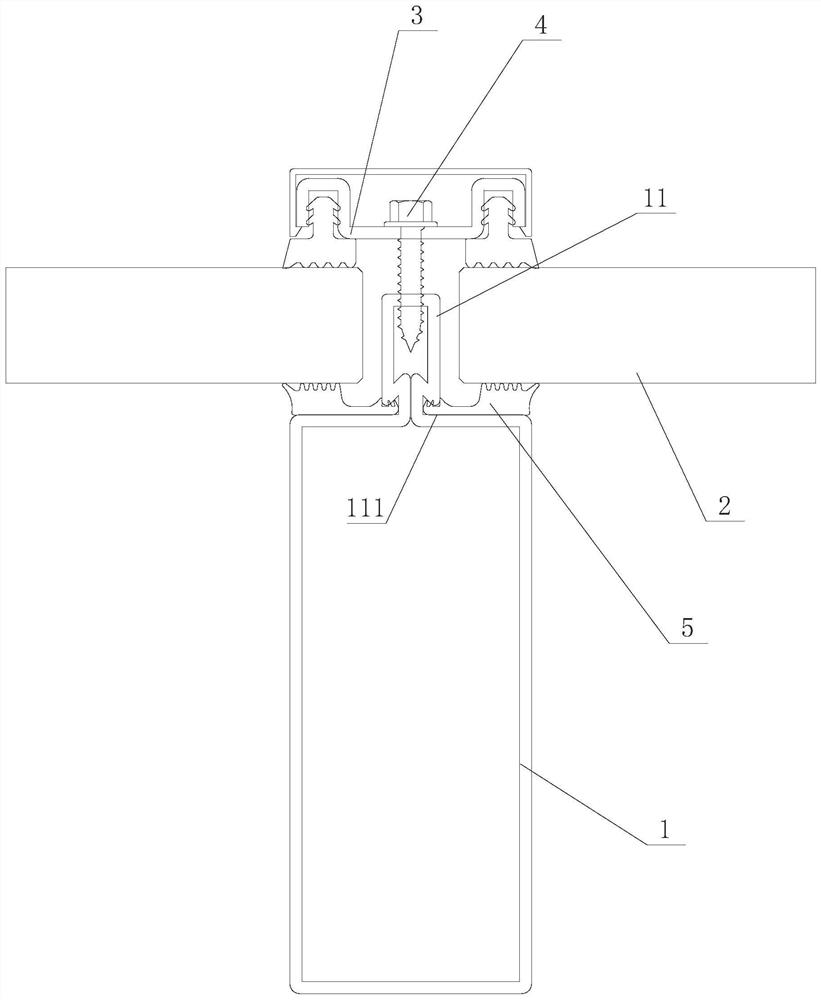

[0030] Such as image 3 As shown, the third embodiment of the curtain wall system of the present invention, the curtain wall system is basically the same as Embodiment 1, the only difference is that in this embodiment, the top surface of the sinking groove 111 is set as a slope, and the top slope makes the sinking groove 111 is an internal expansion groove as a whole. The setting of the inclined surface makes the sinking groove 111 an internal expansion groove as a whole, which further improves the effect of preventing the sealing rubber strip 5 from falling off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com