Equipment for efficiently removing accumulated ash on ash tank base of converter waste heat boiler

A waste heat boiler and converter technology, which is applied to lighting and heating equipment, removal of solid residues, and treatment of combustion products, etc., can solve the problems of incomplete and tight sealing, heavy soot, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

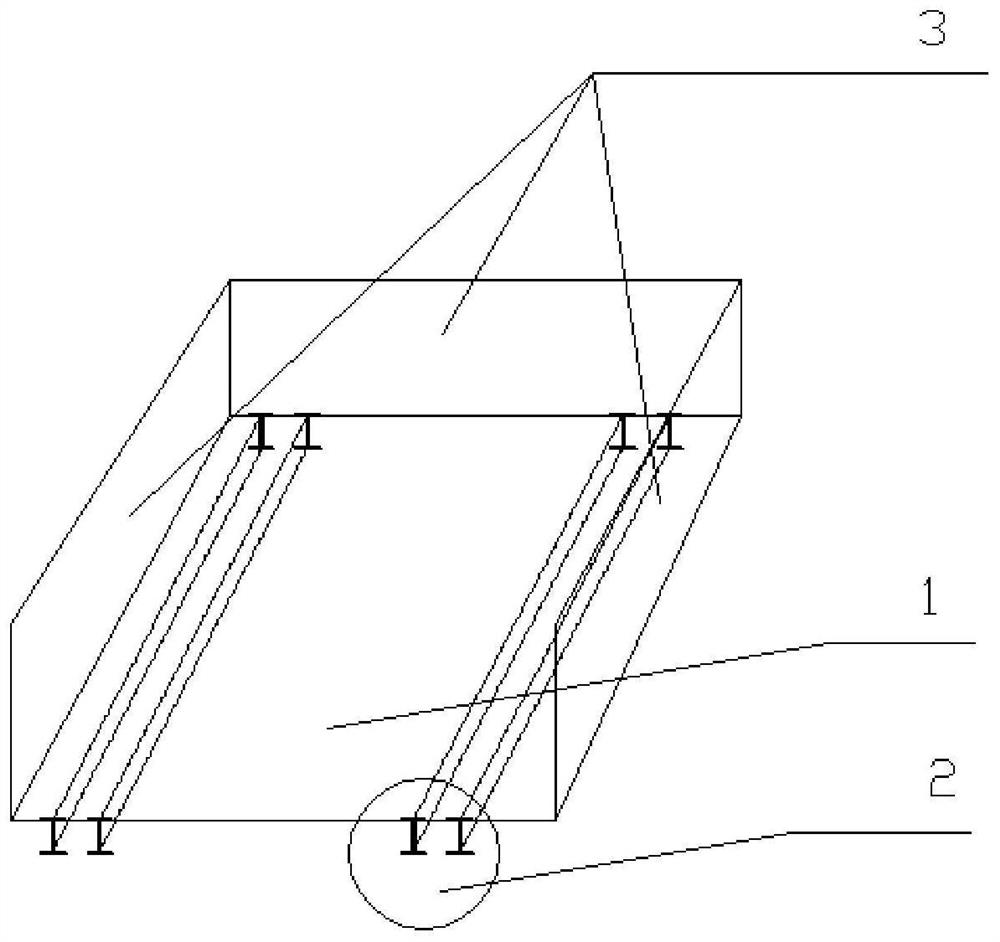

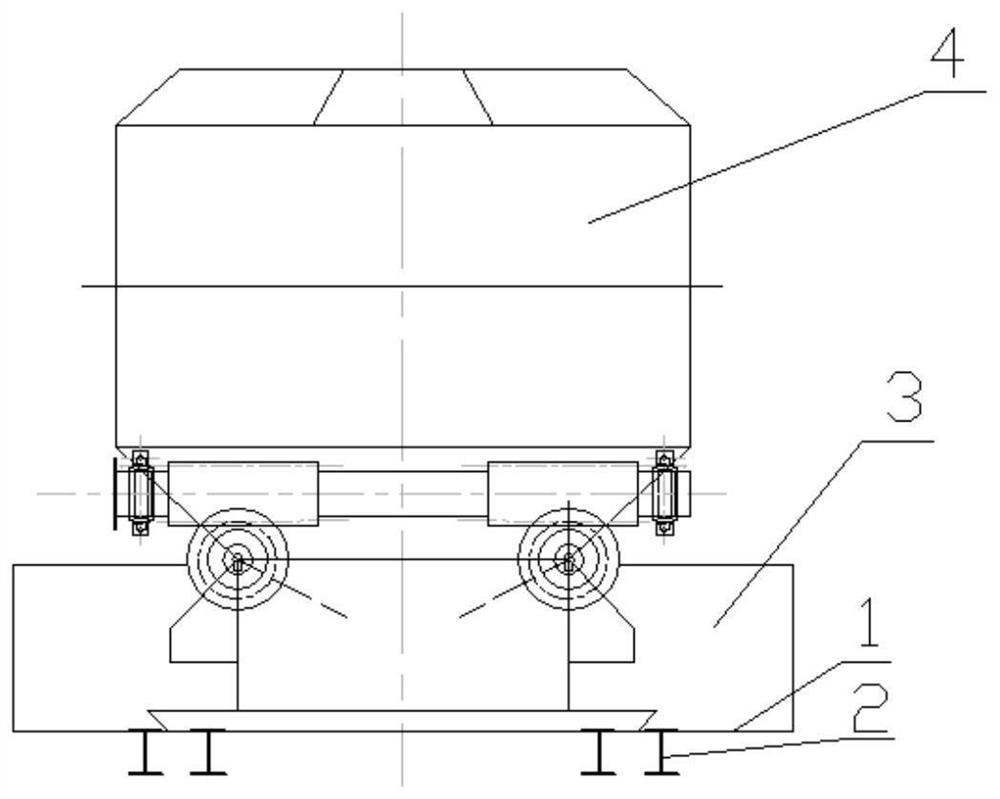

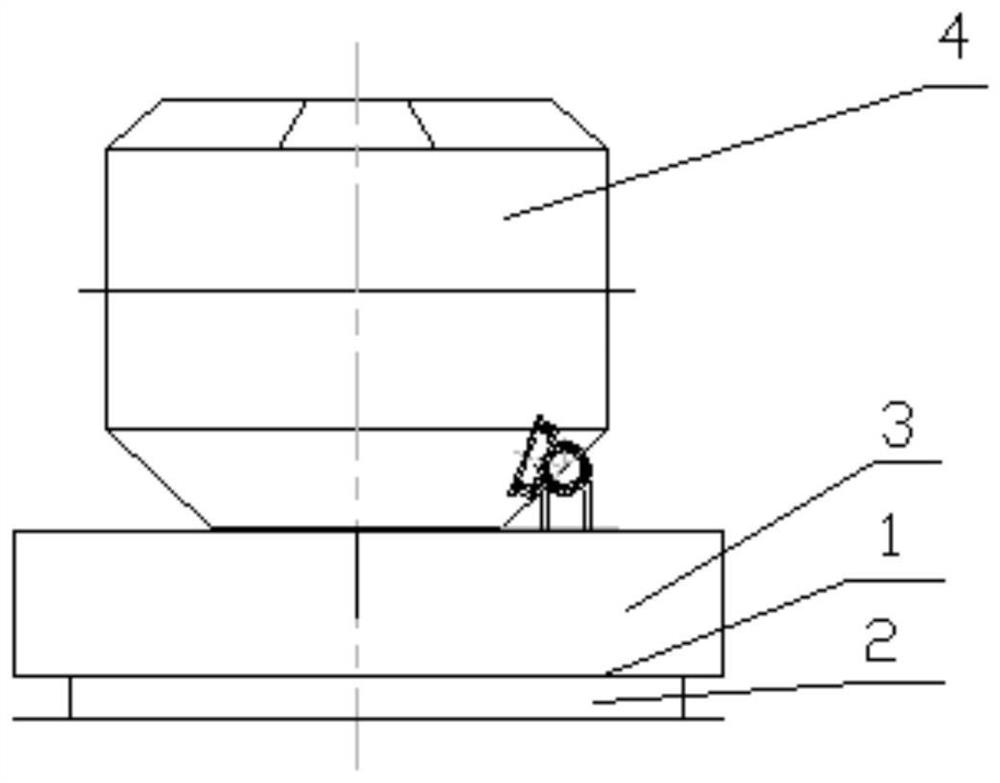

[0017] Please refer to the attached figure 1 As shown, a device for efficiently cleaning the ash tank base of the converter waste heat boiler provided by this embodiment is a device for efficiently cleaning the ash tank base of the converter waste heat boiler, including a base 1, a base support 2 and a baffle plate 3, and the base 1. Three vertical baffles 2 are set at the edge of the top surface. The baffles 2 and the base 1 enclose the top surface and an open ash cleaning space on one side. Two base supports 2 are arranged in parallel on the bottom of the base 1. The base supports 2 is composed of two I-beams arranged in parallel; the open side of the ash removal space is used as the ash removal port, the baffle plate 3 uses ordinary steel plates to block the ash, and the base 1 uses a steel plate with a thickness of 15mm; the two workers forming a single base support 2 The width between the beams is not less than the width of the fork plate of the forklift to ensure that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com