Aggregation dust collecting device for waste plastic film of dry decontamination machine

The technology of a dust collection device and a decontamination machine is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., which can solve the problems that are not conducive to the health of production workers, reduce the cleaning rate of dry decontamination machines, waste plastics, etc. Inconvenient collection of membranes and other issues, to improve the operating environment, eliminate the generation of secondary flying dust, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

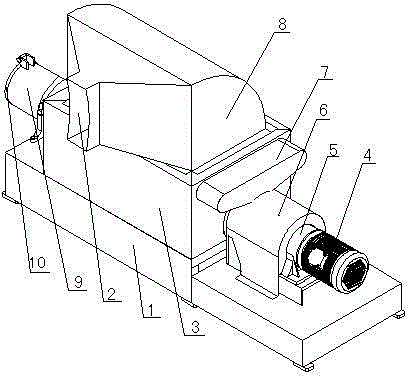

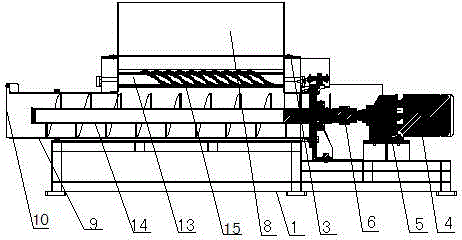

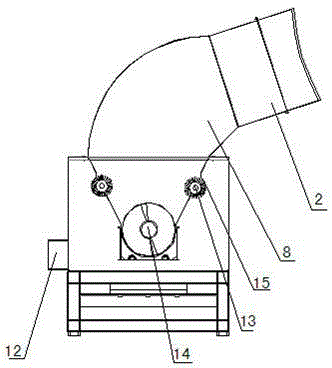

[0022] Example: please combine figure 1 , figure 2 , image 3 , Figure 4 Said, a collection and dust collection device of waste plastic film dry decontamination machine, is characterized in that: said drive system is made up of motor 4, motor transmission 5, and motor 4 is connected with motor transmission 5, and is fixed on the machine The front end of the frame 1; the casing 3 and the barrel 9 are fixed on the rear frame 1, the hopper 8 is fixed directly above the casing 3, and the feed port 2 is arranged on one side of the hopper 8; one end of the barrel 9 is arranged outside the casing 3 , and fixed on the rear end frame 1, the other end of the barrel 9 is located in the cabinet 3, connected with the cabinet 3, and below the brush rod 13; The screw rod 14 that rotates on the barrel 9, one end of the screw rod 14 is connected to the chassis 3, and a cavity is provided between the other end and the discharge port 10, and the bearing of the screw rod 14 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com